Block ice maker with effects of saving energy and protecting environment and facilitating demoulding

An energy-saving, environment-friendly, demoulding technology, which is applied in ice making, ice manufacturing, energy industry, etc., can solve the problems of inconvenient demoulding, waste of resources, insufficient energy conservation and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

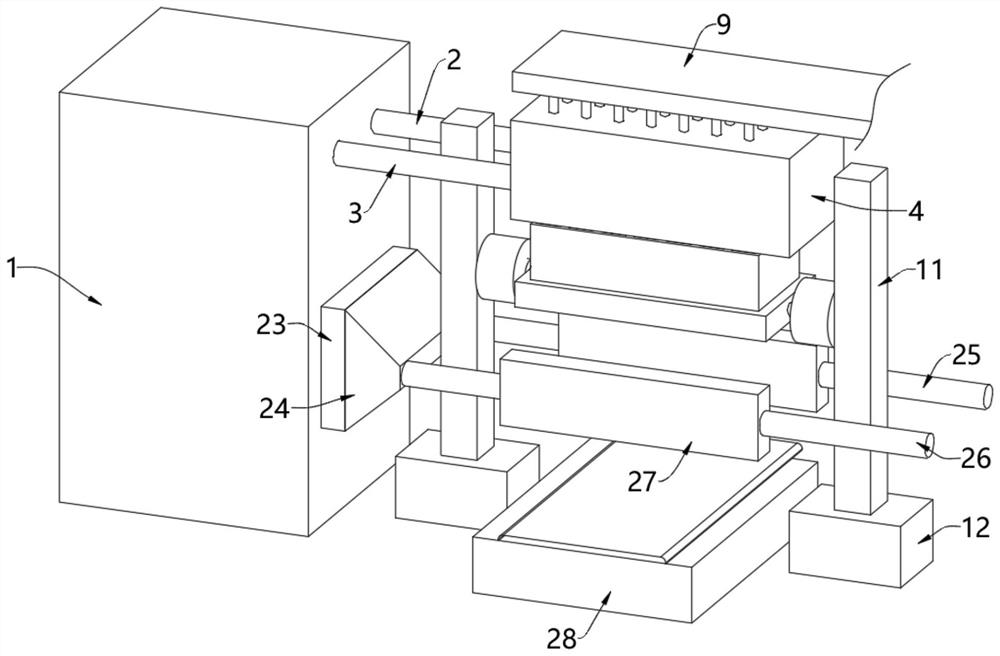

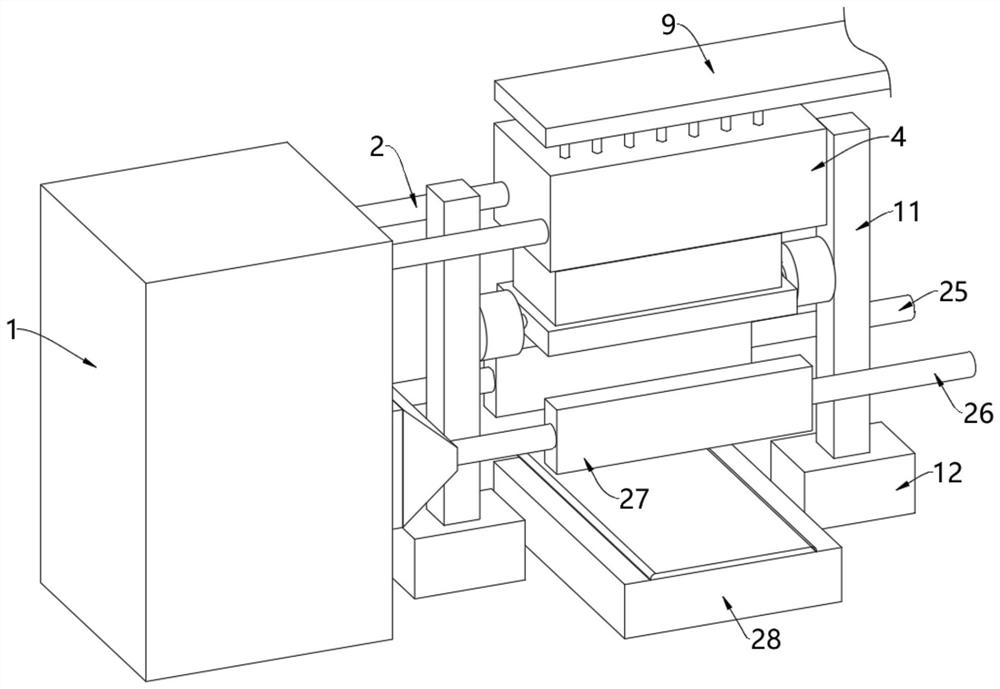

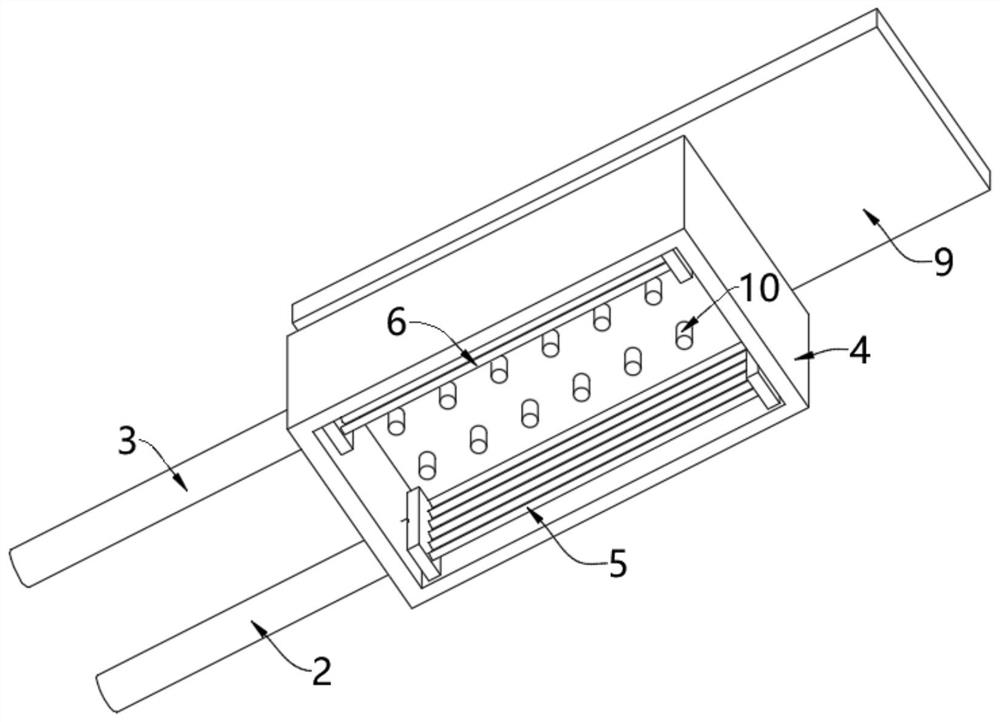

[0037] see Figure 1-Figure 6 , an energy-saving and environmentally friendly ice block machine that is easy to demould, including a refrigeration unit 1, the output end of the refrigeration unit 1 is provided with a first refrigeration pipe 2 and a second refrigeration pipe 3, the first refrigeration pipe 2 and the second refrigeration pipe 3 The ends of the first branch pipe 5 and the second branch pipe 6 are respectively connected through each other, and the first branch pipe 5 and the second branch pipe 6 are fixedly installed on the inner wall of the refrigerator 4 and arranged in an opposite state;

[0038] The bottom of the refrigerator 4 is open and an ice mold 7 is movably arranged at the opening. Several mold grooves 8 are evenly provided inside the ice mold 7. The control device between 11 and the ice mold 7 drives the ice mold 7 to move up and down and turn back and forth;

[0039] The control device includes a first motor 13, a screw mandrel 14, a screw nut 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com