Control method of clothes treating equipment

A technology of clothing processing equipment and control method, which is applied in the control device of washing machine, washing device, textile and paper making, etc., can solve the problems of reduction of moment of inertia change, reduction of precision, reduction of turning radius, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

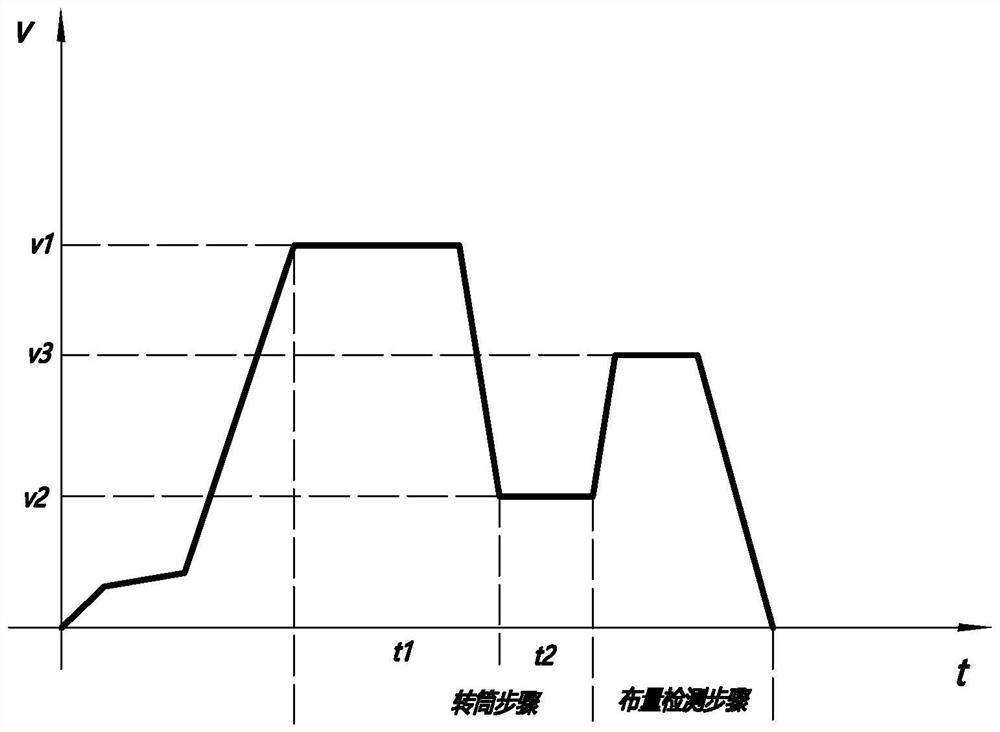

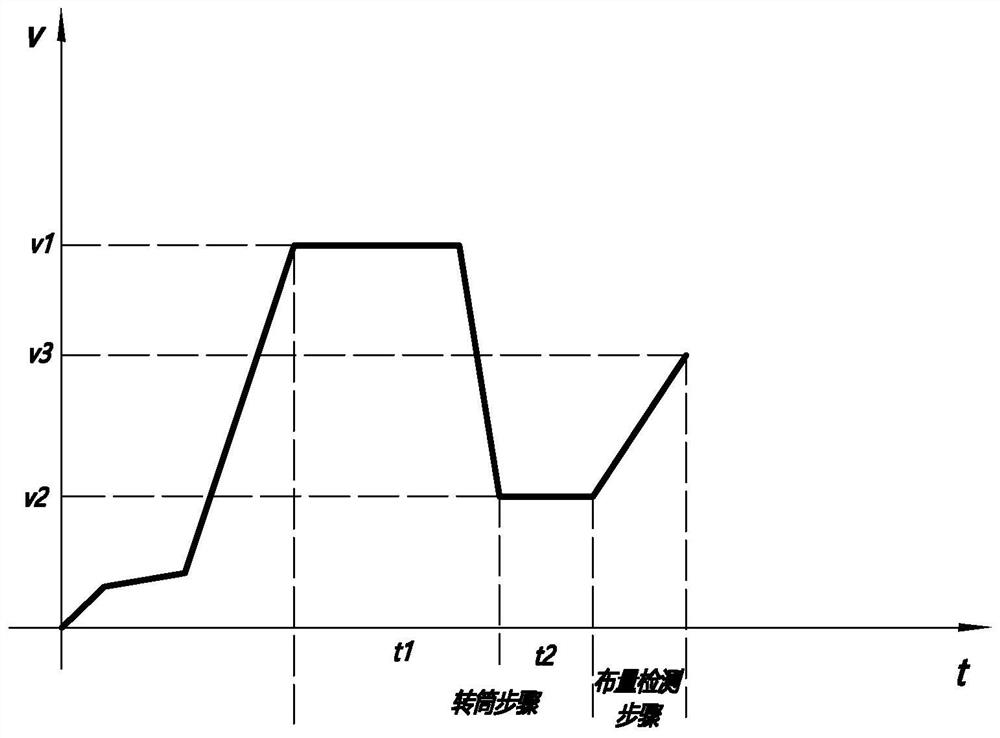

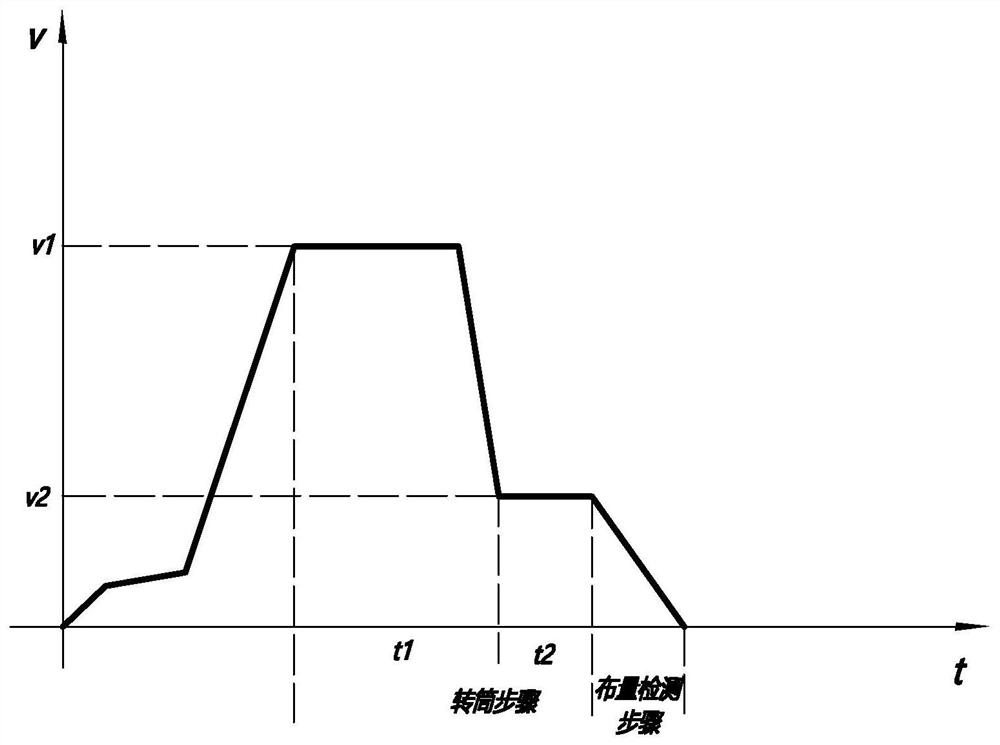

[0047]The control method of the laundry treatment equipment proposed by the present invention, the laundry treatment equipment has a rotatable washing bucket, and the control method includes: the step of rotating the drum, driving the washing bucket to rotate at a first speed v1, so that the clothes in the washing bucket are close to the inside of the washing bucket and, in the cloth amount detection step, driving the washing tub to accelerate and / or decelerate to determine the cloth amount; wherein, the first rotational speed v1 is greater than the maximum rotational speed of the washing tub in the cloth amount detection step.

[0048] The technical solutions of the embodiments of the present invention will be explained and described below in conjunction with the accompanying drawings of the embodiments of the present invention, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implementation ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com