Ultra-width industrial cloth coating and pasting equipment

An industrial cloth and ultra-wide technology, which is applied in the field of industrial cloth coating and pasting equipment, can solve the problems of inconvenient cloth blank roll disassembly and replacement, reduce the processing efficiency of cloth blank coating and pasting, and inconvenience automatic cutting and blanking of fabric blanks, etc., to achieve The effect of improving efficiency, improving practicality and scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

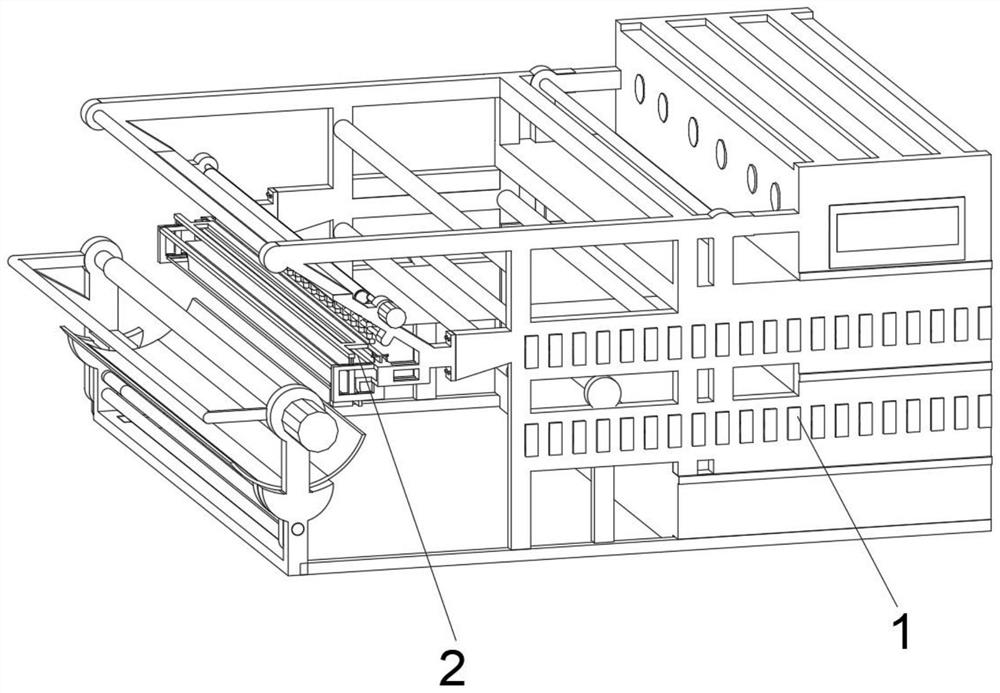

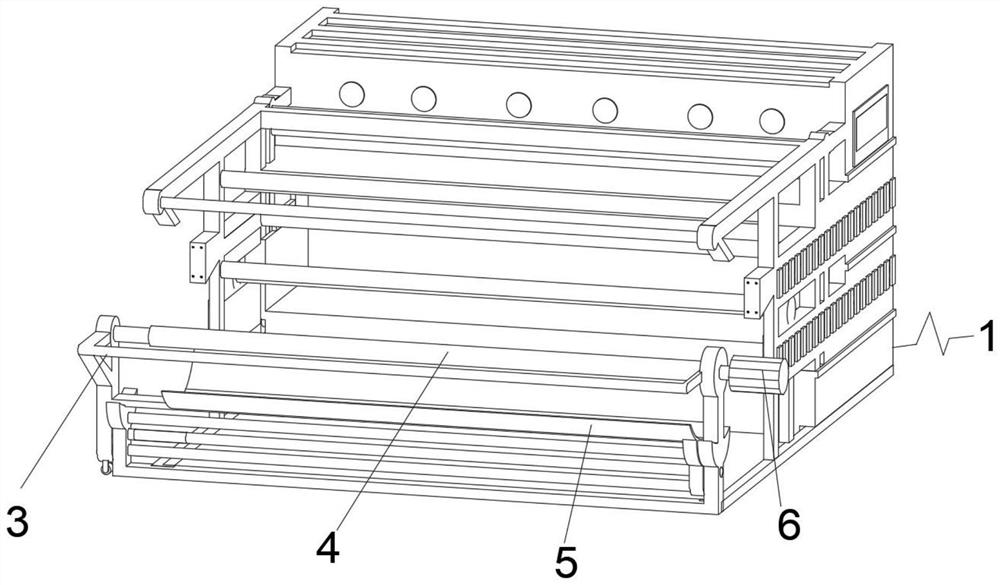

[0033] see Figure 1-7 , an embodiment provided by the present invention: a super-wide industrial cloth coating equipment, including a coating equipment 1 and a cutting device 2, the cutting device 2 is fixedly installed at one end of the coating equipment 1, and the coating equipment 1 The inside includes the blanking frame 3, the winding shaft 4, the arc-shaped receiving plate 5 and the first drive motor 6, the arc-shaped receiving plate 5 is welded on the inner bottom center of the blanking frame 3, and the first driving motor 6 is fixedly installed on the coating equipment 1 on the side edge of one end, the winding shaft 4 is rotatably installed on the upper center edge of one end of the applicator 1, and the unloading rack 3 is slidably installed on the bottom of one end surface of the arc-shaped receiving plate 5;

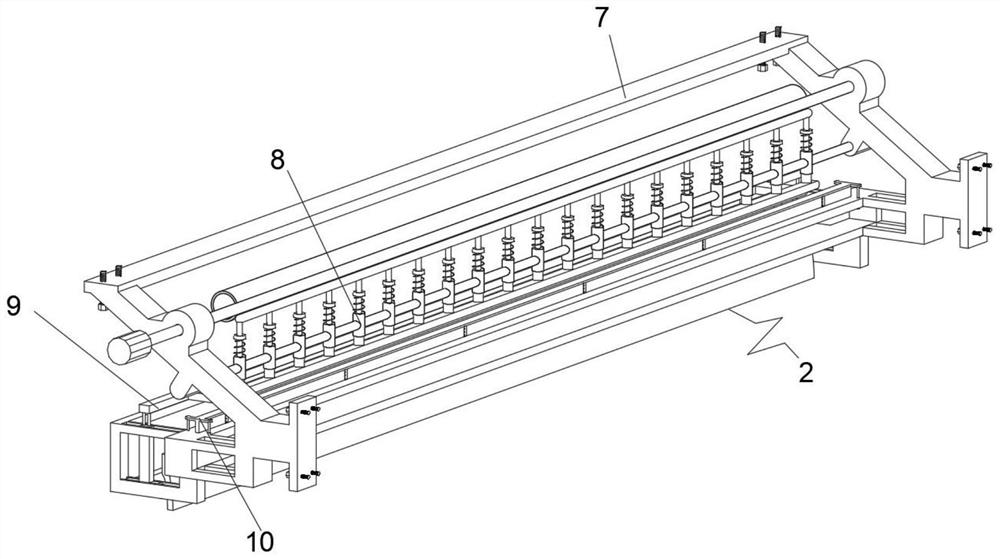

[0034] The inside of the cutting device 2 includes a limit support frame 7, an extruding device 8, a trigger frame 9 and a cutting tool 10. The cutting tool ...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 8 As shown, the side bottom edge of the guide frame 22 is provided with a limit chute 25, and the outer surface of both ends of the trigger rod 21 is spirally connected with a threaded rod 27, and one end of the threaded rod 27 is welded with a turntable 26.

[0045] When this embodiment is implemented, by adjusting the rotation of the threaded rod 27, the two ends of the trigger rod 21 can be slid on the outer surface of the threaded rod 27, and the position of the trigger rod 21 inside the bottom end of the guide frame 22 can be changed. Cloth rolls of different diameters are cut automatically, and the range of use of the trigger frame 9 can be expanded simultaneously.

[0046] Working principle: When coating and pasting the cloth, it is necessary to control the coating equipment 1, the first driving motor 6 and the second driving motor 12 to start running at the same time, and when the second driving motor 12 rotates, it wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com