Cloth inspecting and packaging integrated conveying system

A conveying system and cloth inspection technology, applied in the field of cloth inspection and packaging integrated conveying system, can solve the problems of inability to continuously operate, the packaging mechanism is stuck, and the collection efficiency is low, and achieve the effect of saving manpower, continuous collection, and improving collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

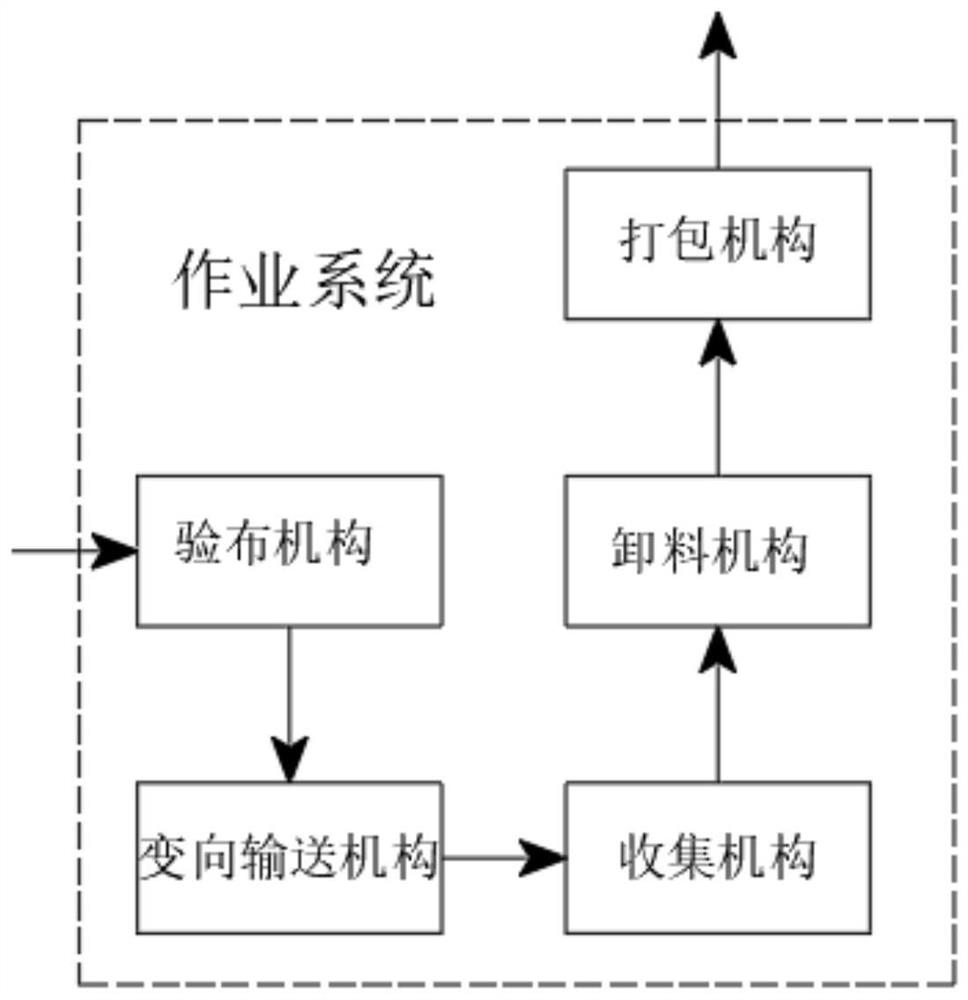

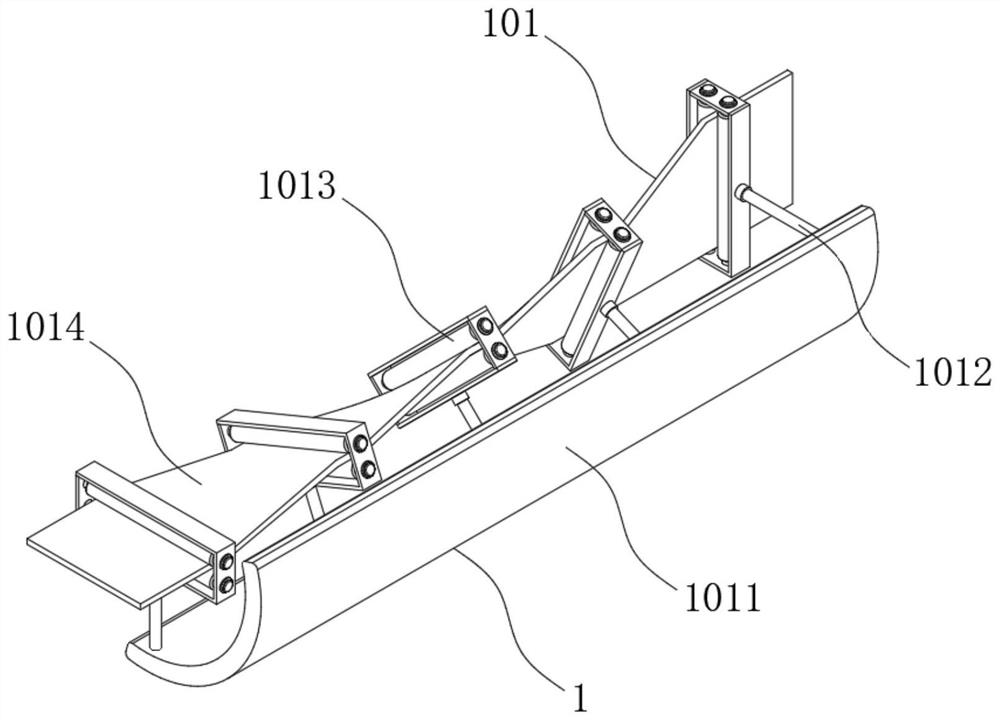

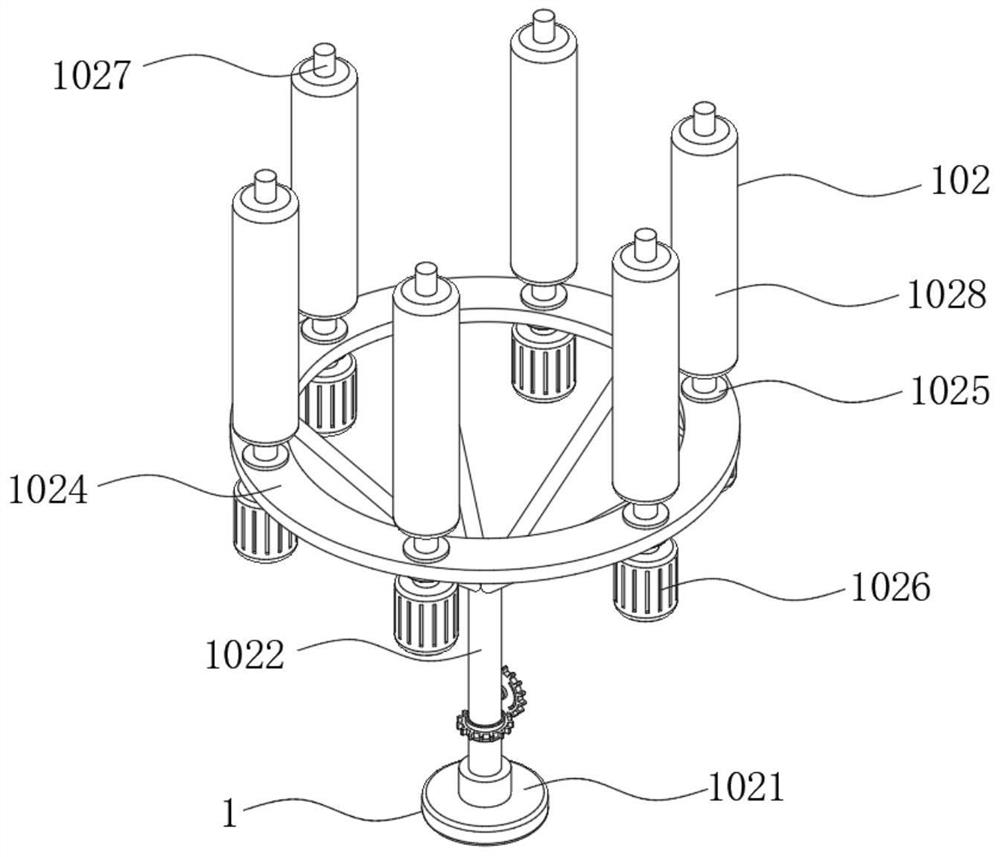

[0030] see Figure 1-6 As shown, the present invention is an integrated delivery system for cloth inspection and packaging, including an operation system 1, and the operation system 1 sequentially includes a cloth inspection mechanism, a direction-changing conveying mechanism 101, a collection mechanism 102, an unloading mechanism 103, and a packaging mechanism, and the collection mechanism 102 The included base 1021 is movably connected with a pillar 1022 at the central position on the upper side, and the upper end of the pillar 1022 is fixedly connected with a slanted column 1023, and the upper end of the slanted column 1023 is fixedly connected with an annular mounting plate 1024, and the inner portion of the annular mounting plate 1024 is arranged in an array and sleeved wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com