An industrial robot that automatically removes interference fit parts

An industrial robot and interference fit technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of high labor intensity, damage, disassembly efficiency and poor effect, and achieve improved effect, increased amplitude, simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

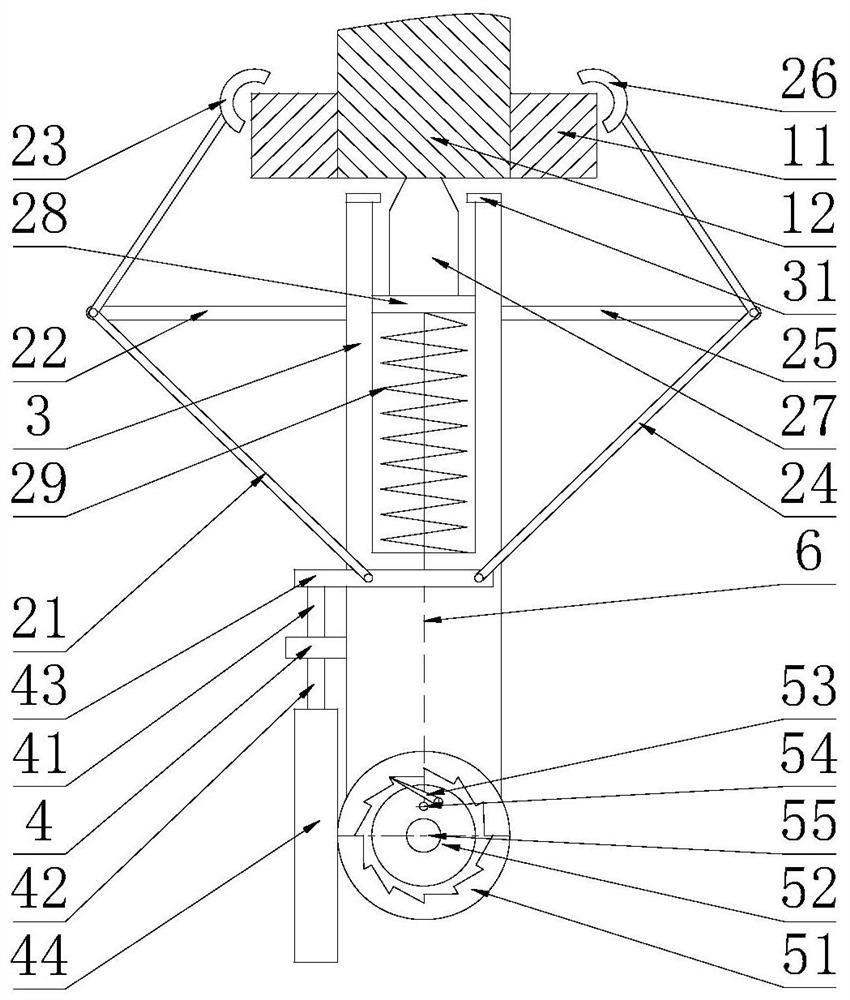

[0016] see figure 1 , an industrial robot that automatically disassembles interference fit parts of the present invention, which includes a U-shaped sleeve frame 3, a part locking device installed on the U-shaped sleeve frame 3 for locking and assembling external parts 11, and a The part impact device for disassembling and assembling the inner part 12 , and the double-rod piston cylinder 4 fixedly installed on the U-shaped sleeve frame 3 .

[0017] The parts locking device includes a horizontal connecting rod A22 and a horizontal connecting rod B25 symmetrically installed on the left and right sides of the U-shaped sleeve frame 3. At the V-shaped link B24 at the right end of the horizontal link B25, the arc clamp A23 fixed on the upper end of the V-shaped link A21, the arc clamp B26 fixed at the upper end of the V-shaped link B24, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com