Gas or liquid ultrasonic purification device

An ultrasonic and liquid technology, applied in the field of gas or liquid purification and purification equipment, can solve the problems of clogging, passivation, filtration and purification efficiency and quality, affecting the production efficiency of enterprises, etc. range, reduce the number of times of opening and flushing, and ensure the effect of filtration and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

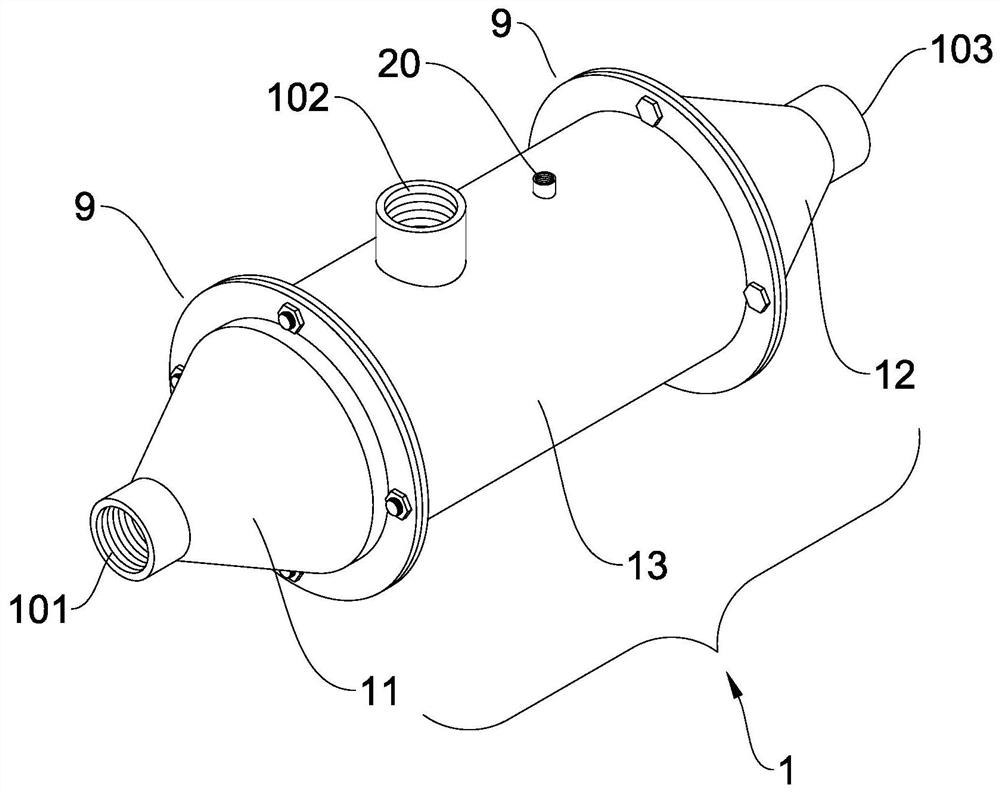

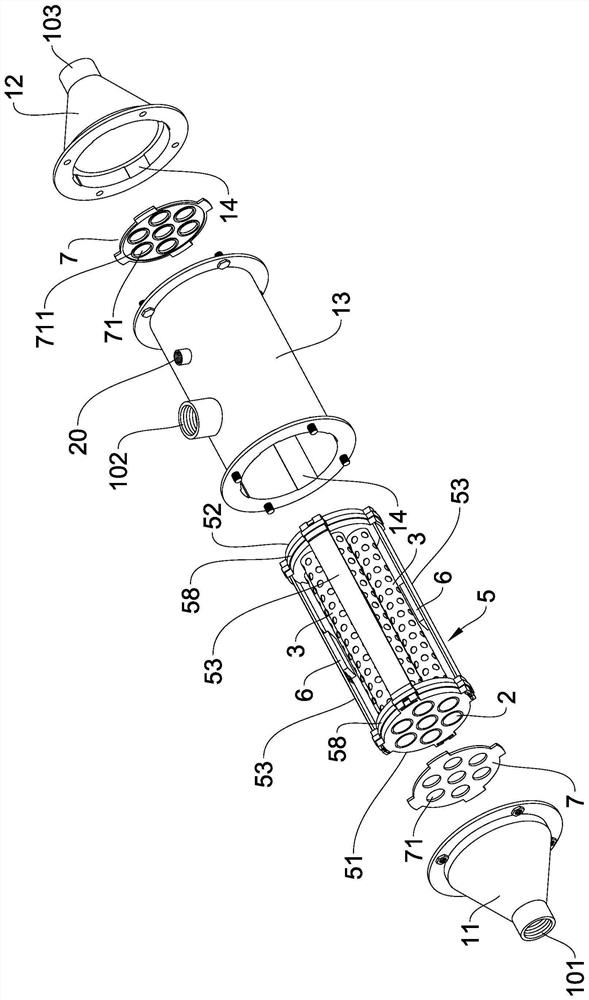

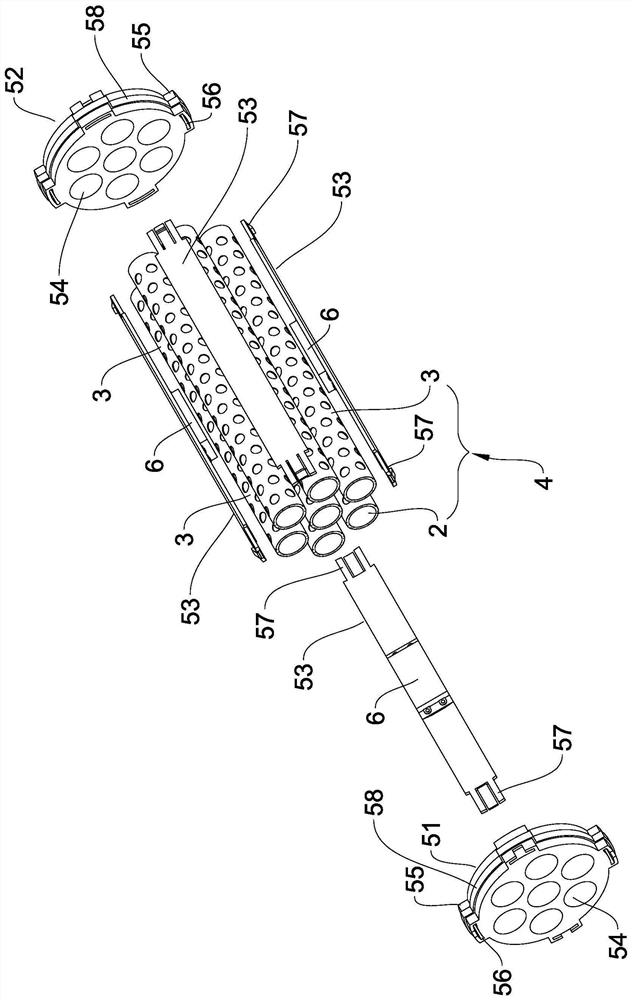

[0014] Such as figure 1 , figure 2 , Figure 5 As shown, a gas or liquid ultrasonic purification and purification device according to the present invention includes the following components: a housing 1, a number of fiber filter tubes 2, a number of hard mesh tubes 3, an internal support body 5, and an ultrasonic vibration element 6;

[0015] Wherein, the housing 1 is an outer shell with at least one end openable and having an input port 101 , a purification output port 102 and a sewage output port 103 . In order to make the shell 1 easy to process, and more convenient to maintain and clean, the preferred scheme of the shell 1 of the present invention is a structure that can be disassembled at both ends, specifically as Figure 5 As shown, the housing 1 includes a front cone cover 11, a rear cone cover 12 and a shell main body 13, and the shell main body 13 is arranged between the front cone cover 11 and the rear cone cover 12 and can be fixed with a flange structure 9. Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com