A kind of preparation method of Faraday cage

A Faraday cage and concentric ring technology, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve the problems of not too large opening density, high cost, slow speed, etc., and achieve good design reduction, Easy to adjust, highly symmetrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

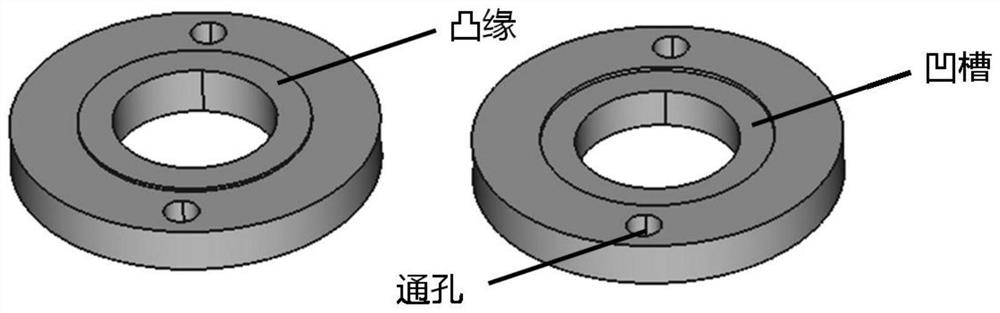

[0016] The preparation method of a Faraday cage provided by the present invention mainly includes two parts. The first part is to design and process the two-dimensional graphics of the planar material, and the second part is to stretch the processed planar material into a three-dimensional shape to obtain the Faraday cage.

[0017] In the first step, according to the parameters of the Faraday cage to be processed, the planar structure of the two-dimensional figure is designed, and the planar material is processed into the corresponding planar structure.

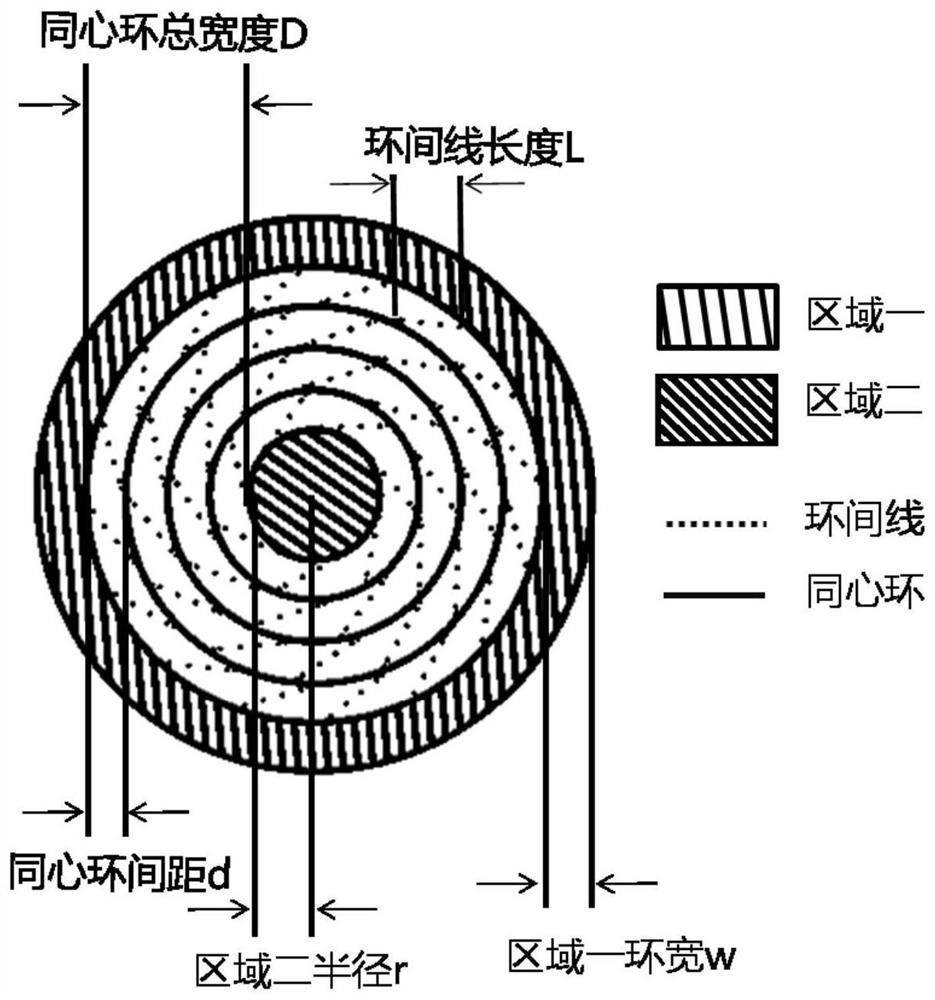

[0018] Such as figure 1 As shown, the two-dimensional image of the planar material designed in the embodiment of the present invention is a circle as a whole, wherein the black part indicates that there is material, the center part and the outer ring part of the image are filled with solid materials,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com