Open-type current transformer and manufacturing method thereof

A current transformer, open-type technology, applied in the field of transformers, can solve the problems of inability to guarantee product qualification rate, difficulty in accuracy level, increase product cost, etc., and achieve the effect of reducing requirements, reducing production costs, and improving yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

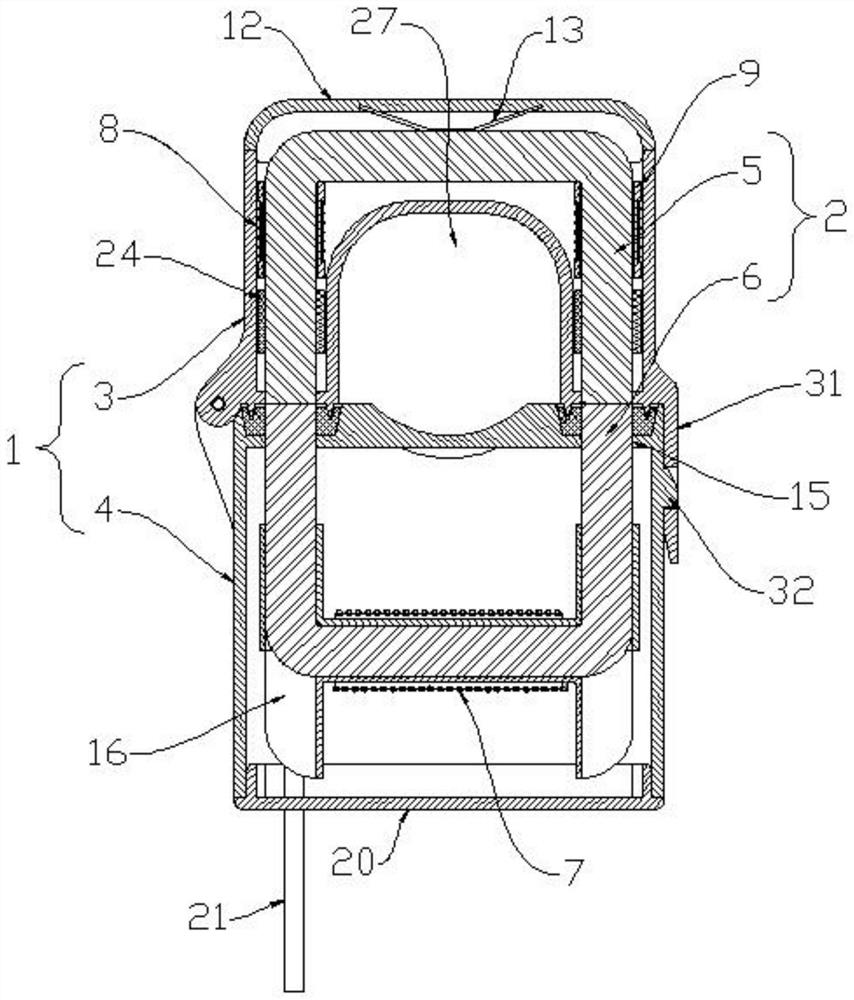

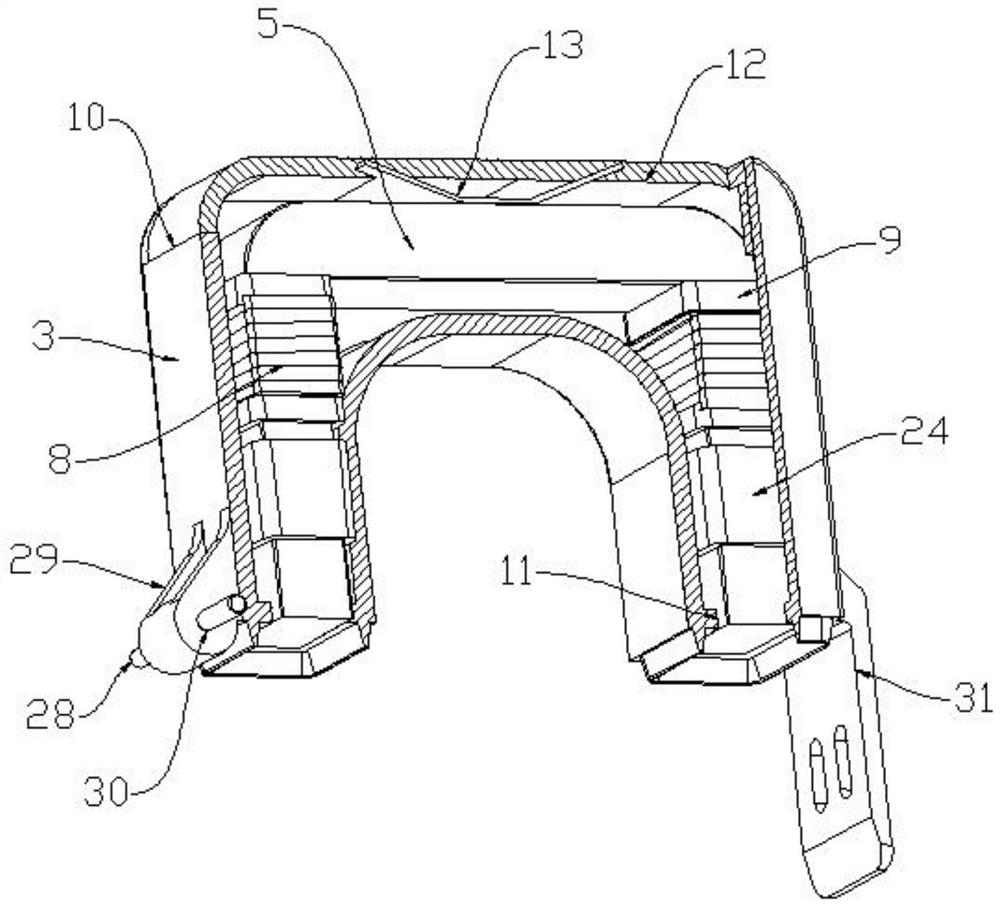

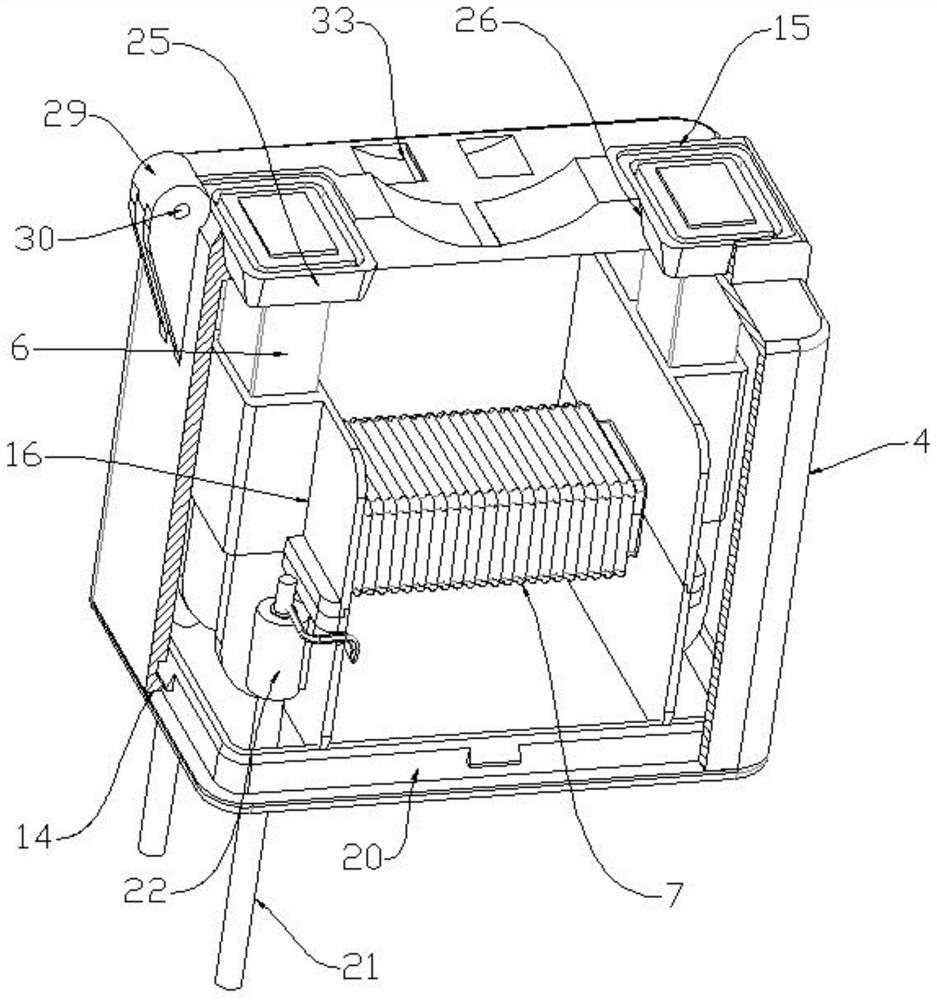

[0029] Such as Figure 1 to Figure 5 As shown, an open current transformer includes a housing 1 and an annular iron core 2; the housing 1 includes an upper housing 3 and a lower housing 4, and the upper housing 3 and the lower housing Active connections between bodies 4. The iron core 2 includes an upper iron core 5 accommodated in the upper housing 3 and a lower iron core 6 accommodated in the lower housing 4, specifically, the upper iron core 5 and the The lower iron cores 6 are U-shaped, and the upper iron core 5 is set opposite to the mouth of the lower iron core 6; when the upper shell 3 and the lower shell 4 are closed, the upper iron core is driven The core 5 is docked with the lower iron core 6 to form a complete iron core 2 . A secondary winding 7 is wound on the lower iron core 6 , and a compensation winding 8 is arranged on the upper iron core 5 .

[0030] Among them, the compensation winding 8 arranged on the upper iron core 5 without the secondary winding 7 nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com