Printing Defect Detection Method Based on Adaptive Focus

A detection method and a technology for printing defects, which are applied to color TV parts, TV system parts, instruments, etc., can solve problems such as multiple printing of printed products, inability to judge, and affect user experience, so as to improve reliability, Detect precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

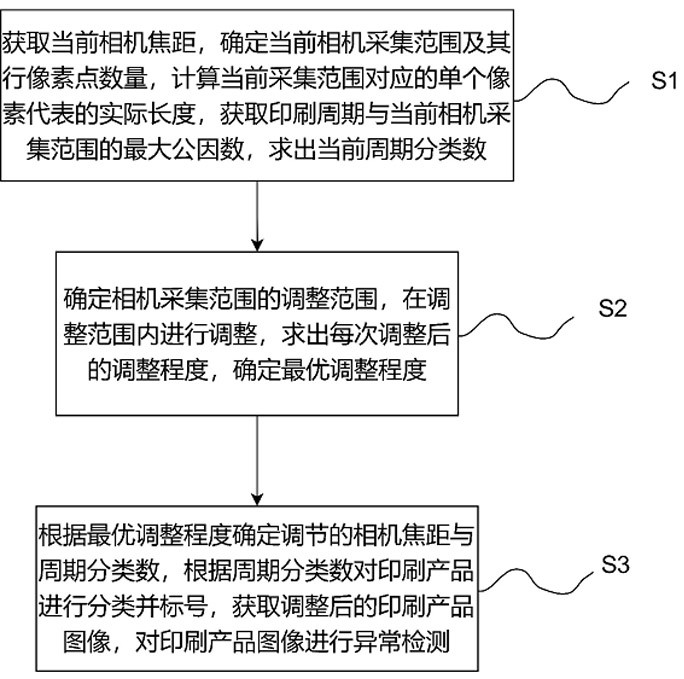

[0064] The method includes:

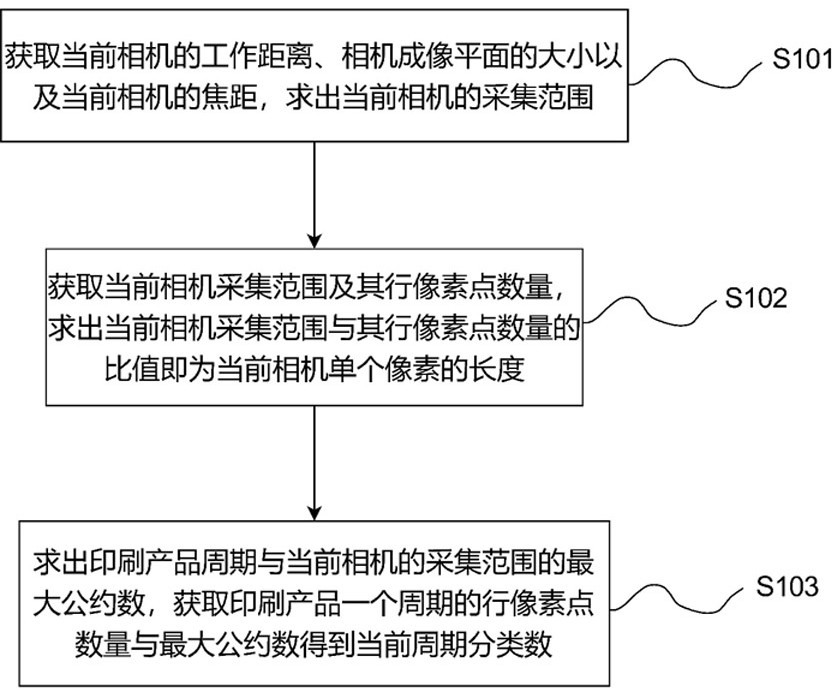

[0065] S1: Obtain the current camera focal length, determine the current camera acquisition range and the number of row pixels, calculate the actual length represented by a single pixel in the current acquisition range, obtain the cycle of the printed product and the number of row pixels in one cycle, and determine the print product The greatest common factor of the cycle and the current camera acquisition range is used to find the classification number of the current cycle;

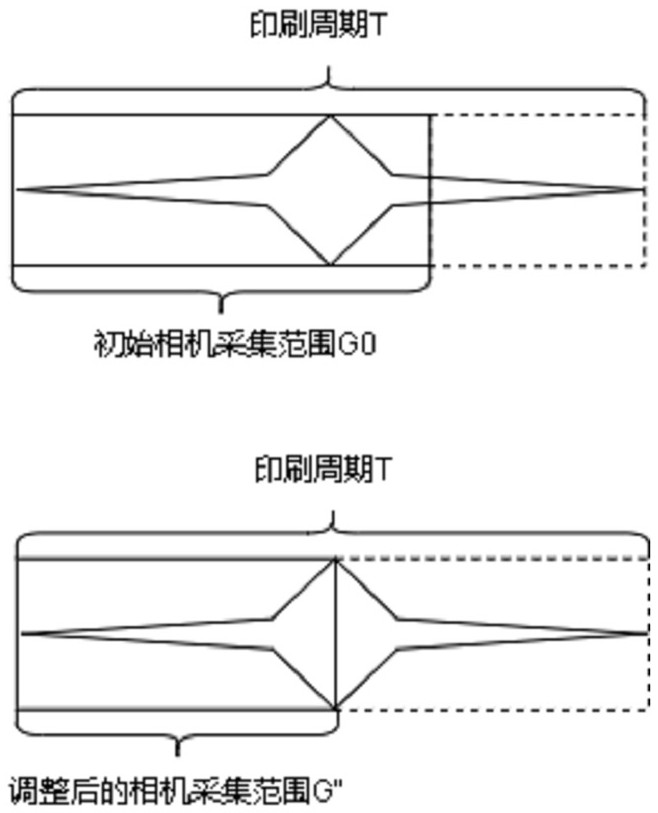

[0066] S2: Determine the adjustment range of the camera acquisition range, adjust within the adjustment range, find the number of cycle classifications and the length of a single pixel corresponding to each adjusted acquisition range, calculate the corresponding adjustment degree after each adjustment, and determine the optimal degree of adjustment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com