Inner wall cleaning device for heat exchange tube and method thereof

An inner wall cleaning and heat exchange tube technology, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of complicated cleaning equipment, incomplete cleaning, cumbersome process, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

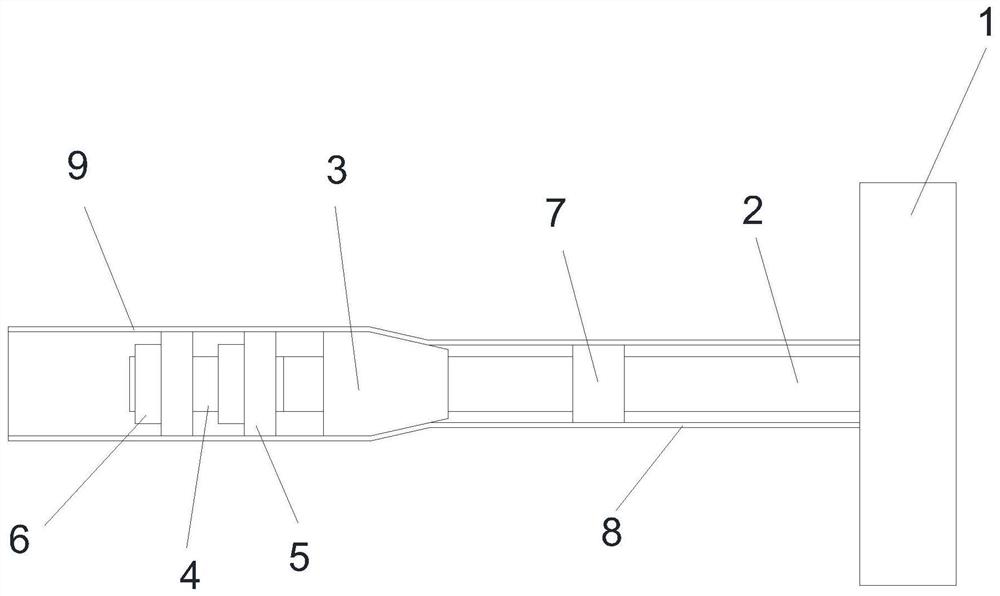

[0013] Embodiment 1 refers to figure 1 , a cleaning device for the inner wall of a heat exchange tube, comprising a rolling mill 1, one end of a core rod 2 connected to the rolling mill, the other end of the core rod is provided with an inner mold 3, the other end of the core rod is located outside the inner mold and is also connected to an inner hole deoiling core rod 4, the inner The hole deoiling mandrel is provided with a tube wall deoiling member 5 for inserting into the heat exchange tube and sticking to the inner wall of the heat exchange tube for deoiling.

[0014] A heat exchange tube inner wall cleaning device, the tube wall deoiling part is a polyurethane sealing block.

[0015] The outer surface of the pipe wall deoiling member is attached to the limit ring 6 arranged on the core rod.

[0016] An oil guide groove is arranged on the outer surface of the polyurethane sealing block. The cross-section of the tube wall deoiling part facing the inner mold is conical, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com