Buffer type oil pipe

An oil pipe and pipe body technology, applied in the field of pipeline design, can solve problems such as easy damage of oil pipes, and achieve the effects of improving installation stability, avoiding overheating damage and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

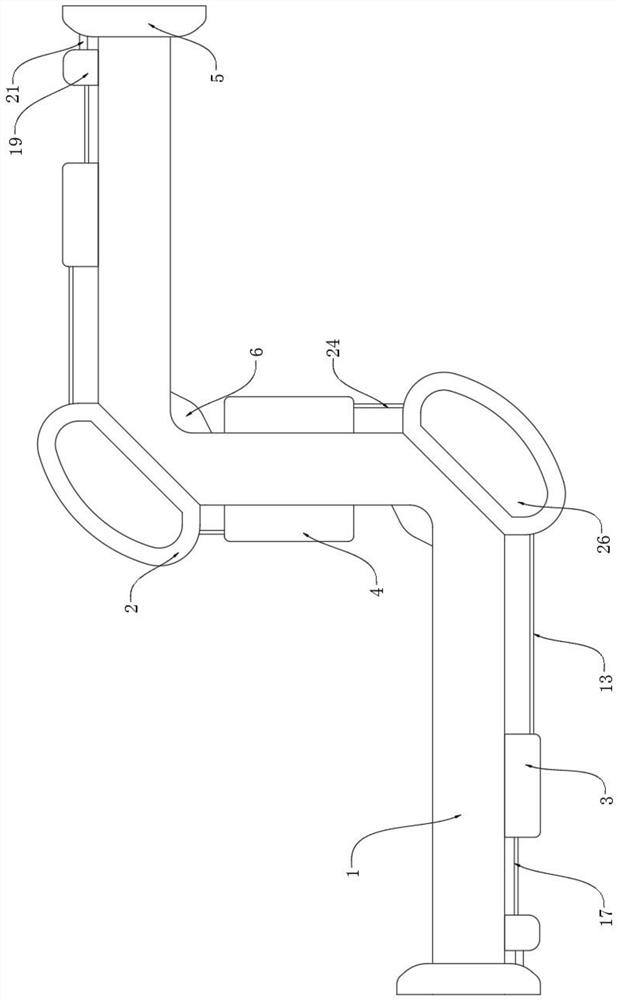

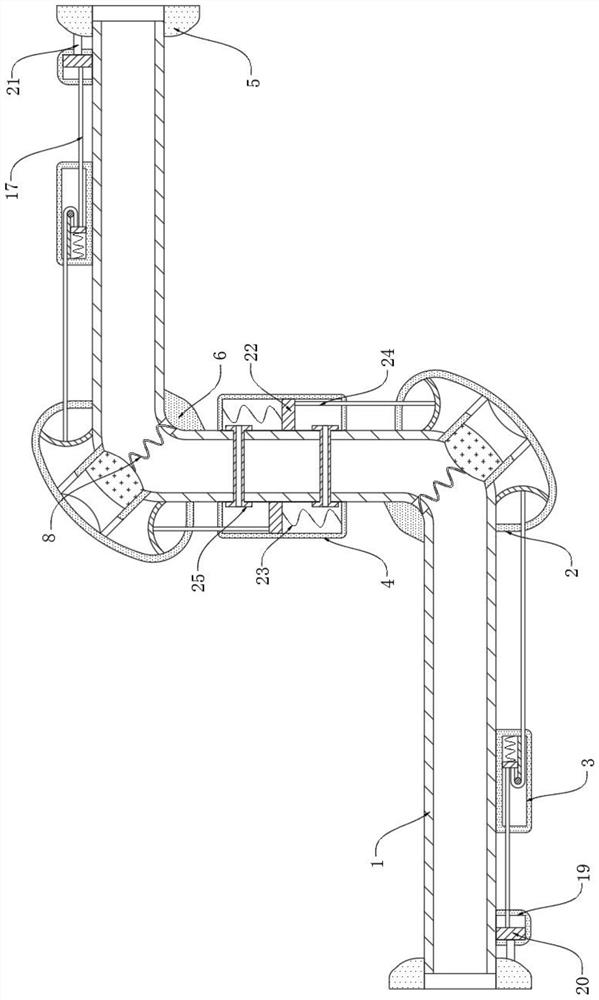

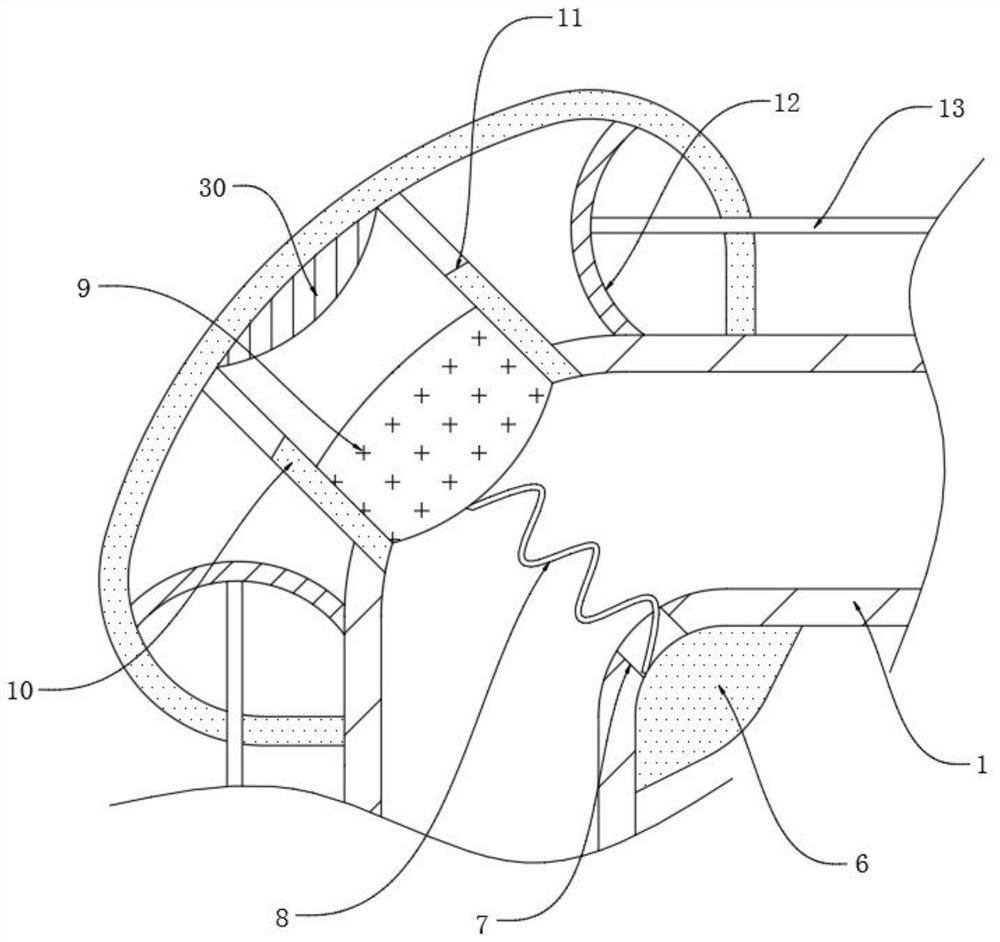

[0025] refer to Figure 1-5 , a buffer type oil pipe, including a pipe body 1 and two corner guards 2 installed at two corners of the pipe body 1, the inside of the two corner guards 2 are equipped with a force unloading mechanism, and the side wall of the pipe body 1 is fixed with Two reversing boxes 3, the inside of the two reversing boxes 3 are equipped with a reversing mechanism, both ends of the pipe body 1 are fixed with a stabilizing plate 5, and the side wall of the pipe body 1 is fixed with two suction boxes 19 and Two cooling boxes 4 and two suction boxes 19 are provided with supercharging mechanisms, and the insides of the two cooling boxes 4 are provided with heat-absorbing mechanisms. The upper ends of the two corner guards 2 are fixed with warning boxes 26, and the two The inside of each warning box 26 is provided with an alarm triggering mechanism.

[0026] The unloading mechanism includes two partitions 10 fixed on the inner wall of the corner guard 2, the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com