Method for detecting flow characteristic offset fault of CV control valve

A flow characteristic, high-profile technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems affecting the safety and stable operation of the unit, and achieve the effect of reliable data analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

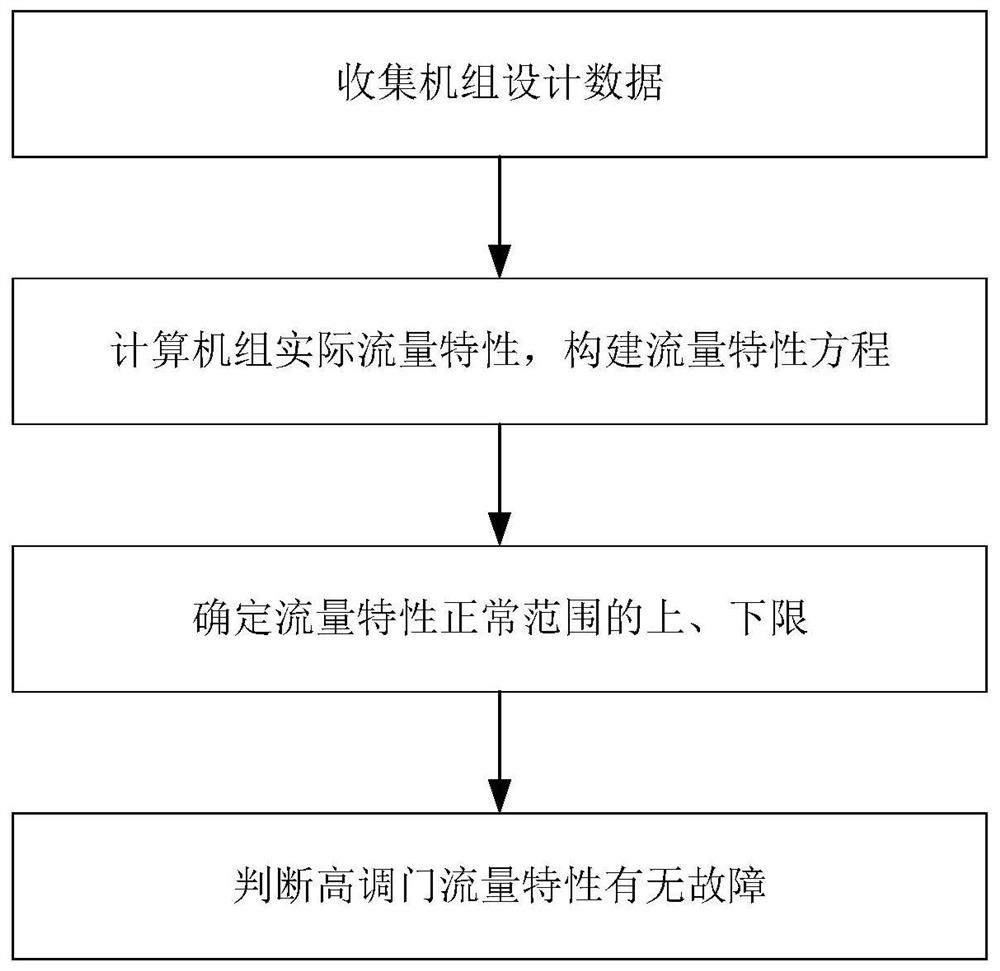

[0041] Embodiment 1, with reference to Figure 1-Figure 4 Describe this implementation mode, a method for detecting a high-profile door flow characteristic deviation fault, including the following steps:

[0042] S110 collects unit design data; the unit design data includes unit rated working condition data and unit failure-free historical data.

[0043] Specifically, the main steam flow rate, the regulating stage pressure, the regulating stage temperature, and the exhaust pressure of the high-pressure cylinder under the rated working condition of the unit;

[0044] Specifically, the history data of the unit without failure is specifically the historical data collected in the DCS system of the comprehensive flow command, the pressure of the regulating stage, the exhaust pressure of the high-pressure cylinder, and the temperature of the regulating stage.

[0045] The actual flow characteristics of the S120 computer group, and construct the flow characteristic equation;

[0046]...

Embodiment 2

[0066] Embodiment 2, with reference to Figure 1-Figure 4 Describe this implementation mode, a method for detecting a high-profile door flow characteristic deviation fault, including the following steps:

[0067] S110 collects unit design data; the unit design data includes unit rated working condition data and unit failure-free historical data.

[0068] Specifically, the actual main steam flow ratio, regulating stage pressure, regulating stage temperature and high discharge pressure under the rated working condition of the unit;

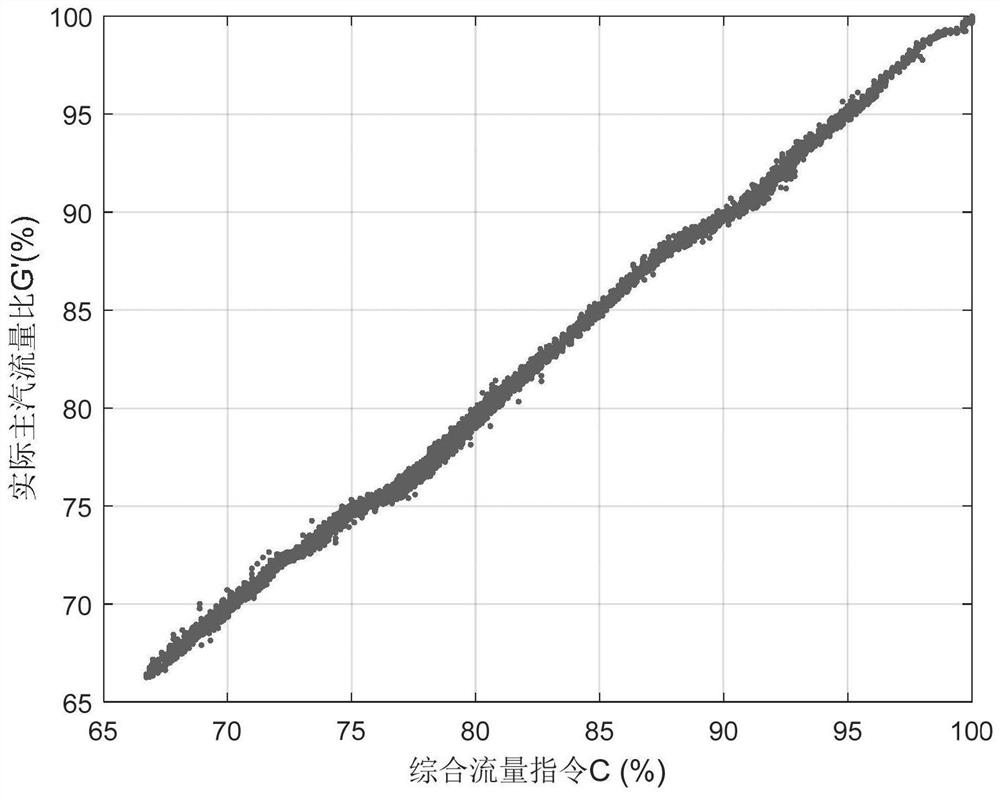

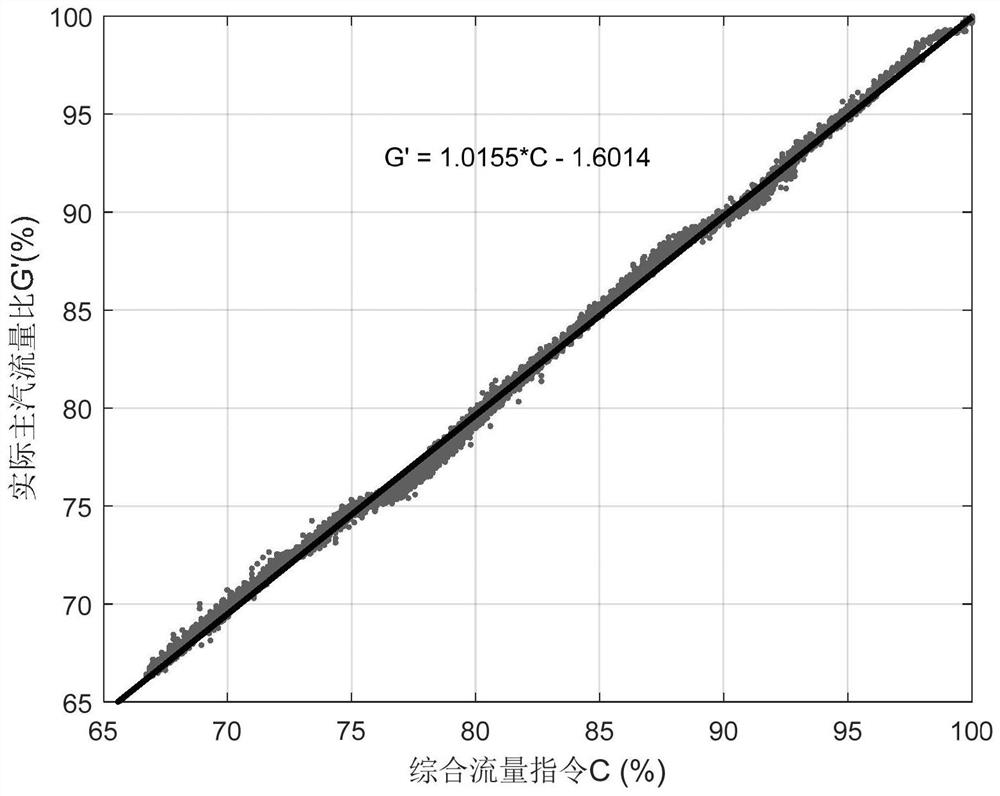

[0069] Specifically, the historical data of the unit without faults is specifically the historical data of the comprehensive valve position command, regulating stage pressure, high exhaust steam temperature, regulating stage temperature and other parameters collected in the DCS system and the actual flow characteristics of the S120 computer unit;

[0070] The collected data at a certain moment of collecting unit design data is shown in Table 1 (col...

Embodiment 3

[0086] Embodiment 3 is different from Embodiment 2 in that this embodiment adopts the support vector machine (SVM) algorithm to fit the flow characteristic curve of the unit in step S120 (calculating the actual flow characteristics of the group) described in Embodiment 2.

[0087] Suppose you have training data:

[0088] (x 1 ,y 1 ), (x 2 ,y 2 ),..., (x n ,y n ), x∈R n , y∈{-1,+1} (11)

[0089] Then the hyperplane is:

[0090] w*x+b=0 (12)

[0091] Then the distance from the support vector to the hyperplane is:

[0092]

[0093] For support vectors, there are

[0094] y(w T x+b)=|w T x+b|=1 (14)

[0095] Bringing formula (19) into formula (18) can convert the maximum segmentation distance into solving the following optimization problem:

[0096]

[0097] s.t.1-y i [(w*x t +b)]≤0, i=1, ..., n (15)

[0098] Introducing the Lagrangian multiplier α i Transform this into a dual problem:

[0099]

[0100]

[0101] The values of w and b can be obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com