A method for producing chromium-containing high carbon steel by using stainless steel dust

A stainless steel and high-carbon steel technology, applied in the field of metallurgy, can solve problems such as long production process, low metal recovery efficiency, complex recovery system, etc., and achieve the effects of reducing the amount of chromium alloy used, good environmental benefits, and simplifying the reduction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

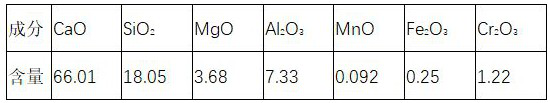

Embodiment 1

[0042] A method for producing chromium-containing high-carbon steel by utilizing stainless steel dust as a resource in LF furnace. 2 : 4-12% (wt), TFe: 30-35% (wt), TCr: 10-15% (wt), TNi: 0.5-1.5% (wt), MnO: 2-5% (wt), MgO : 2-5% (wt) and a very small amount of other oxides. The experimental furnace number 20210987 was used, the refining cycle of the LF ladle furnace was 58 minutes, and the heating time was 27 minutes.

[0043]Step 1: Treat the molten steel before entering the refining process to keep the carbon content in the molten steel at 0.75% and the oxygen content in the molten steel at 20 ppm.

[0044] Step 2: After the molten steel enters the station, adjust the bottom blowing argon for 40m 3 / h, add the first batch of active lime 5kg / t for slagging, 1kg / t refining slag, and 2kg / t fluorite.

[0045] Step 3: During the first heating process, adjust the bottom blowing argon for 30m 3 / h, the stainless steel dust briquettes are added to the ladle furnace in three bat...

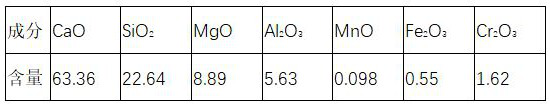

Embodiment 2

[0052] A method for producing chromium-containing high-carbon steel by utilizing stainless steel dust as a resource in LF furnace. 2 : 4-12% (wt), TFe: 30-35% (wt), TCr: 10-15% (wt), TNi: 0.5-1.5% (wt), MnO: 2-5% (wt), MgO : 2-5% (wt) and a very small amount of other oxides. The experimental steel furnace number 20311765 was used, the refining cycle of the LF ladle furnace was 55 minutes, and the heating time was 25 minutes.

[0053] Step 1: Treat the molten steel before entering the refining process to keep the carbon content in the molten steel at 0.78% and the oxygen content in the molten steel at 18 ppm.

[0054] Step 2: After the molten steel enters the station, adjust the bottom blowing argon for 30m 3 / h, add the first batch of active lime 4.4kg / t, refining slag 1.2kg / t and fluorite 2.4kg / t.

[0055] Step 3: During the first heating process, adjust the bottom blowing argon 20m 3 / h, add 4kg / t of stainless steel dust briquettes into the ladle furnace in three batches...

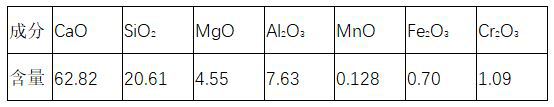

Embodiment 3

[0062] A method for producing chromium-containing high-carbon steel by utilizing stainless steel dust as a resource in LF furnace. 2 : 4-12% (wt), TFe: 30-35% (wt), TCr: 10-15% (wt), TNi: 0.5-1.5% (wt), MnO: 2-5% (wt), MgO : 2-5% (wt) and a very small amount of other oxides. The experimental steel grade is 82B, the heat number is 20311767, the refining cycle of the LF ladle furnace is 58 minutes, and the heating time is 26 minutes.

[0063] Step 1: Treat the molten steel before entering the refining process to keep the carbon content in the molten steel at 0.78% and the oxygen content in the molten steel at 23 ppm.

[0064] Step 2: After the molten steel enters the station, adjust the bottom blowing argon for 40m 3 / h, add the first batch of active lime 5kg / t for slagging, 1.4kg / t refining slag, and 2kg / t fluorite.

[0065] Step 3: During the first heating process, adjust the bottom blowing argon 20m 3 / h, add 2.6kg / t stainless steel dust-removing ash briquette into the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com