Production process of anti-static wall cloth

A production process and anti-static technology, applied in the field of wall coverings, can solve the problems of wall coverings smell polluting the indoor environment, not having odor absorption effect, blocking, etc., and achieve the effects of avoiding thermal fatigue loss, ensuring stability, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

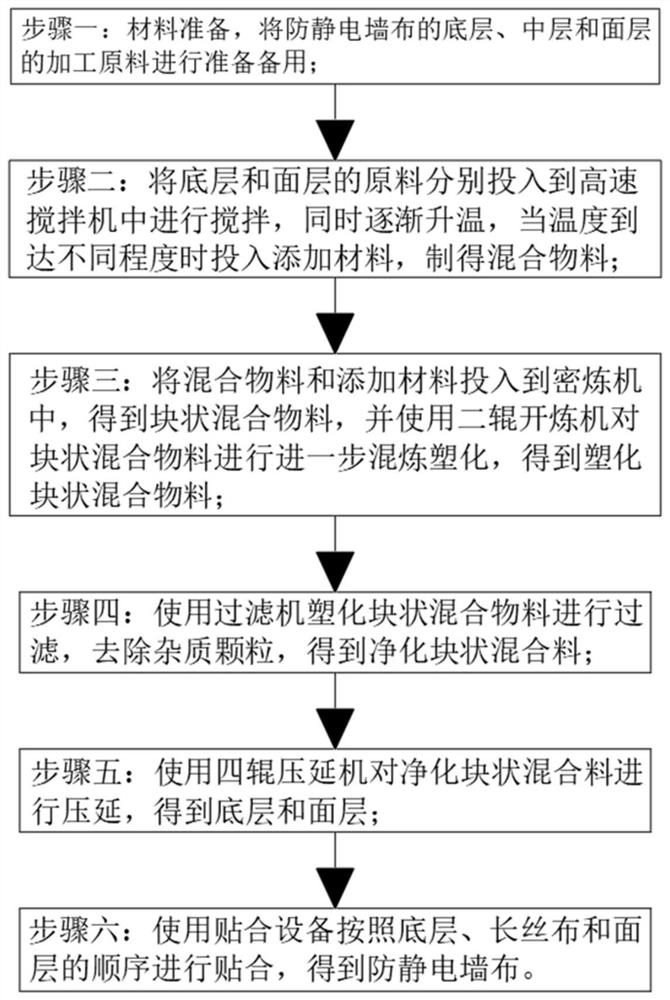

[0051] see figure 1 , the present invention provides a technical solution: a production process of antistatic wall cloth, comprising the following steps,

[0052] Step 1: Material preparation, prepare the processing raw materials for the bottom layer, middle layer and surface layer of the anti-static wall covering;

[0053] Step 2: Put the raw materials of the bottom layer and the surface layer into the high-speed mixer for stirring, and gradually increase the temperature at the same time. When the temperature reaches different levels, add materials to make a mixed material;

[0054] Step 3: put the mixed material and the added material into the internal mixer to obtain the block mixed material, and use the two-roller open mill to further knead and plasticize the block mixed material to obtain the plasticized block mixed material;

[0055] Step 4: Use a filter to plasticize the bulk mixture for filtering, remove impurity particles, and obtain a purified block mixture;

[005...

Embodiment 2

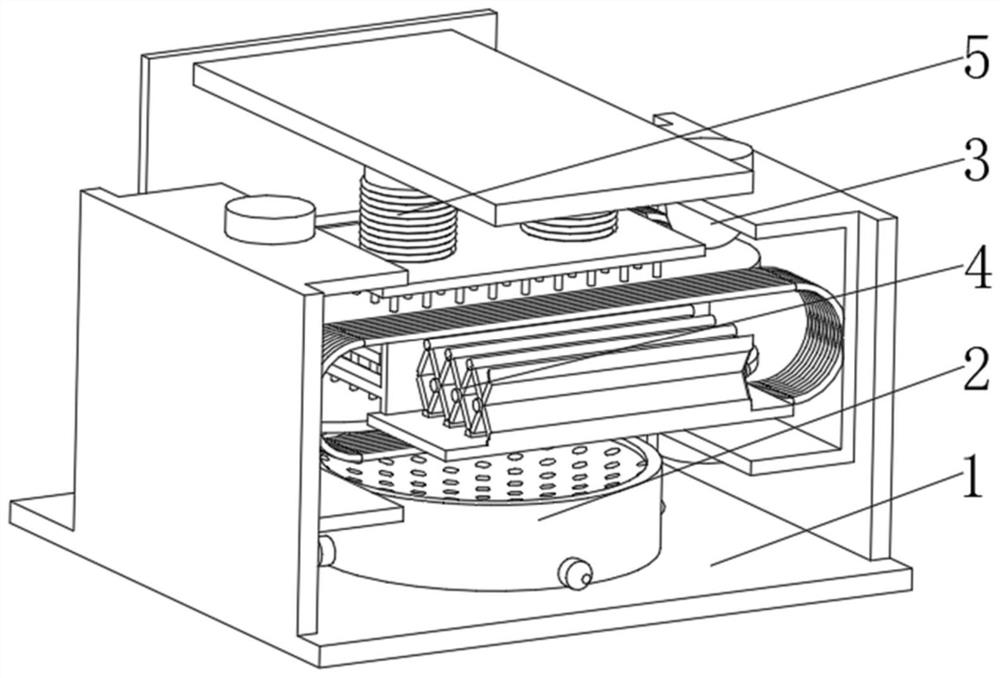

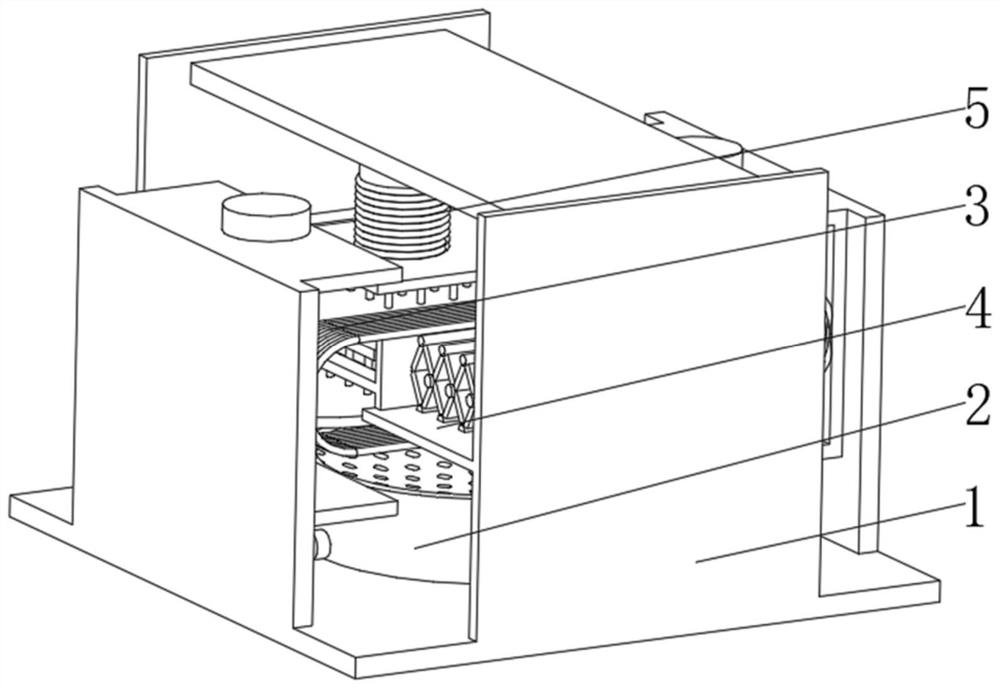

[0059] see Figure 2-7 , on the basis of Embodiment 1, the present invention provides a technical solution: an anti-static wall covering laminating equipment, specifically comprising:

[0060] The installation frame board box 1 has a square box body, and an air circulation device 2 installed at the middle position of the bottom of the square box inner cavity, and a bonding device 3 installed at the middle position of the inner wall on both sides of the square box body, And the layering device 4 installed on the front and back of the inner cavity of the square box, and the positioning device 5 installed in the middle of the top of the inner cavity of the square box, and the internal and external contact area of the equipment is increased through the design of the space left in the mounting frame board box 1 , to facilitate its flowing flow and heat exchange, avoid thermal fatigue loss of components caused by high temperature during processing of equipment components, prolong ...

Embodiment 3

[0070] see Figure 2-7 , on the basis of Embodiment 2, the present invention provides a technical solution: a method for using anti-static wall covering laminating equipment, comprising the following steps,

[0071] Step 1: Turn on the external power supply, so that each electric component inside the device is powered on;

[0072] Step 2: Start the columnar air pump 22 in the airflow circulation device 2, so that the air flows downward from the middle position inside the equipment, passes through the through air holes 24 on the spherical carrier plate 23, and then is output by the columnar air pump 22 to the surroundings;

[0073] Step 3: Place the surface layer on the top of the sheet metal plate 44 in the layering device 4, place the filament cloth between the sheet metal plates 44, and place the bottom layer on the top of the bonding plate 34 located below in the bonding device 3;

[0074] Step 4: Start the heating coil 36, and start the telescopic rhombic frame 43 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com