Efficient processing device for biodegradable high-barrier plastic film material

A plastic film, biodegradable technology, applied in the field of plastic film processing, to achieve the effect of fast drying and convenient fixing of film base film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

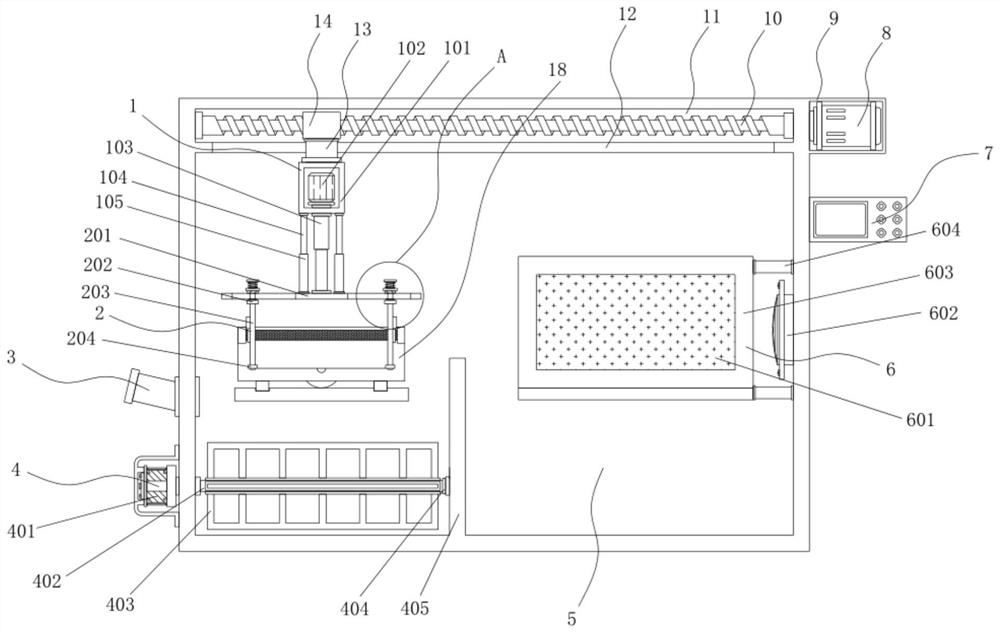

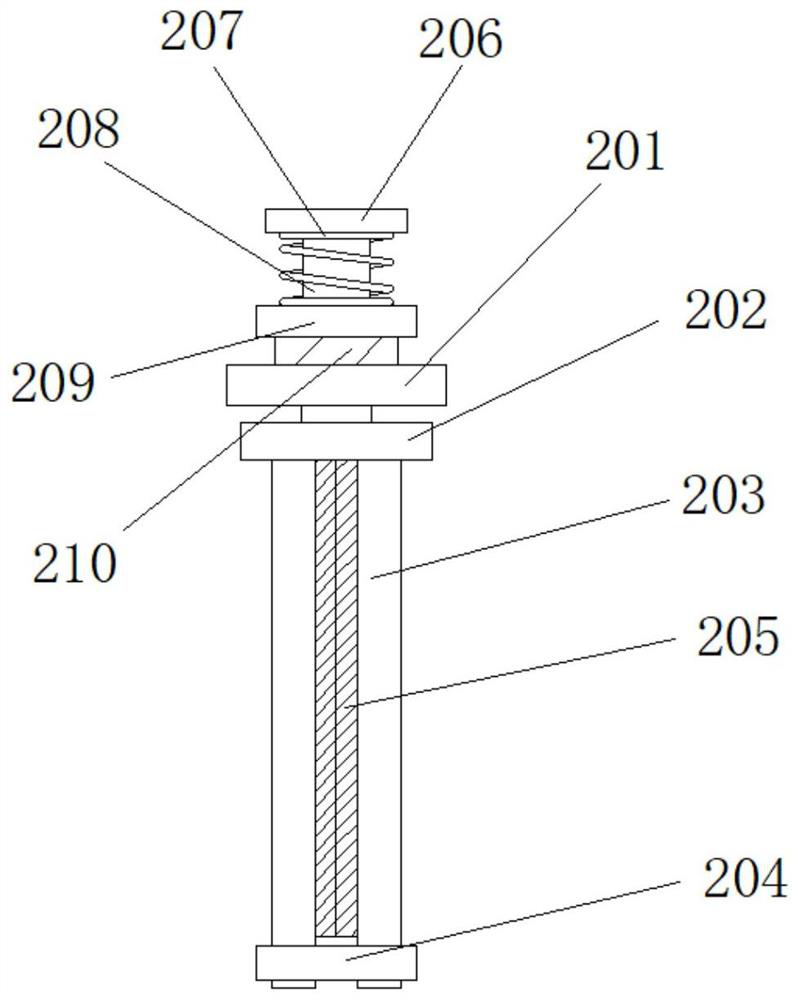

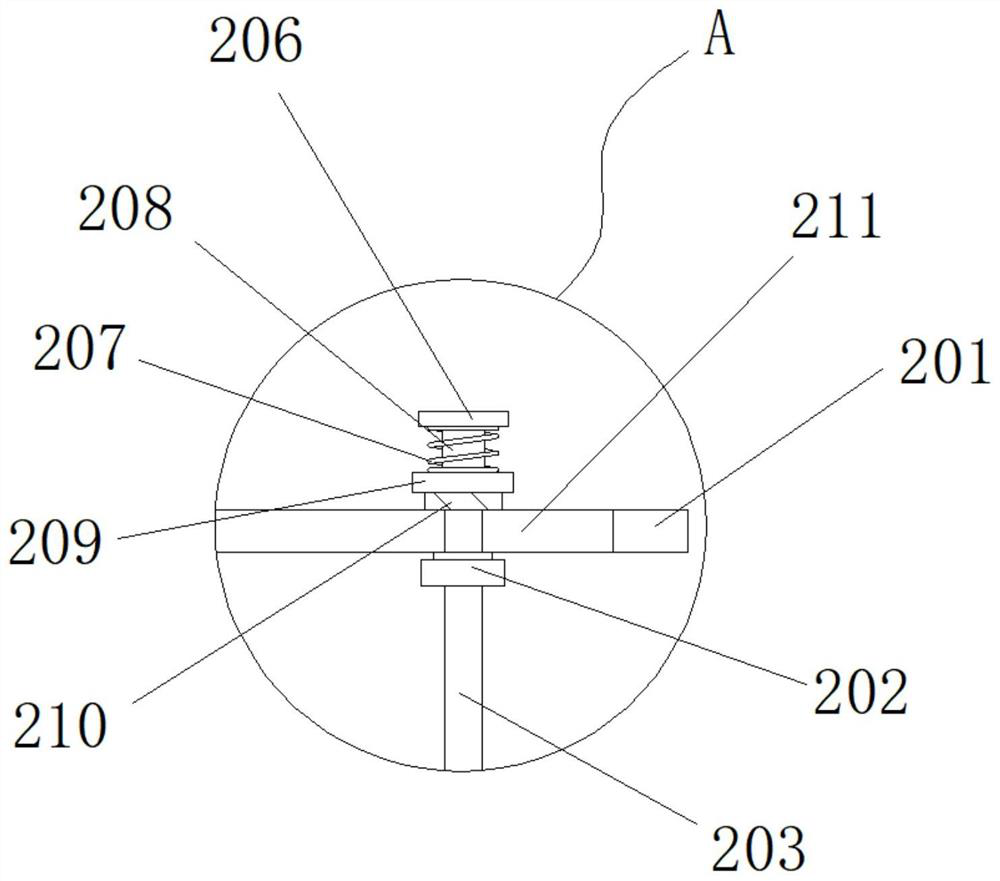

[0039] Example 1: See Figure 1-7 , a high-efficiency processing device for biodegradable high-barrier plastic film materials, comprising a feed pipe 3 and a box body 5, one side of the box body 5 is fixedly connected with the feed pipe 3, and the top inside the box body 5 is provided with a soaking mechanism 1 , the bottom of the soaking mechanism 1 is provided with a clamping structure 2, one side of the inner bottom of the box body 5 is provided with a stirring mechanism 4, a dehumidification mechanism 18 is arranged above the stirring mechanism 4, and a drying mechanism is arranged at one side of the box body 5 6. One side of the box body 5 is fixedly connected with a control panel 7, one end of the box body 5 is inlaid with a slot 15, and both sides of one end of the box body 5 are respectively fixedly connected with a set of sliding sleeves 16, and the inner movable connection of the sliding sleeve 16 is Cover body 17, the top of box body 5 is provided with driving mecha...

Embodiment 2

[0043] The drive mechanism includes a top box 11, which is fixedly connected to the top of the box body 5, one side of the top box 11 is fixedly connected with a side box 9, and the inside of the side box 9 is fixedly connected with a servo motor 8, the type of the servo motor 8 is It is HG-KN13J-S100. The output end of the servo motor 8 runs through one side of the top box 11 and extends to the inside of the top box 11. A screw 10 is fixedly connected to the inside of the top box 11. The outside of the screw 10 is movably connected to a threaded sleeve 14. The threaded sleeve The bottom end of the barrel 14 is fixedly connected with a connecting block 13, and the top of the box body 5 is inlaid with a hollow groove 12, and the connecting block 13 penetrates the hollow groove 12 and extends to the inside of the box body 5;

[0044] The length of the top case 11 is equal to the length of the casing 5, and the height of the threaded sleeve 14 is less than the height inside the to...

Embodiment 3

[0046] Embodiment 3: Soaking mechanism 1 is made up of installation box 101, cylinder 102, telescopic rod 103, limit rod 104 and limit cylinder 105, and installation box 101 is fixedly connected to the bottom end of connection block 13, and the interior of installation box 101 is fixedly connected There is a cylinder 102, the model of the cylinder 102 is SC50, the output end of the cylinder 102 runs through the bottom end of the installation box 101 and extends to the bottom end of the installation box 101, and a telescopic rod 103 is fixedly connected, and the two sides of the bottom end of the installation box 101 are respectively fixedly connected There is a group of limit rods 104, and the outside of the limit rods 104 is connected with a limit cylinder 105;

[0047] The center line of the telescopic rod 103 is on the same vertical plane as the center line of the installation box 101, and the center line of the installation box 101 is on the same vertical plane as the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com