Raw material pretreatment method for solid wood board

A pretreatment and pretreatment liquid technology, applied in wood treatment, wood treatment details, wood processing equipment, etc. Damage and other problems, to achieve the effect of ensuring service life, avoiding damage, and improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

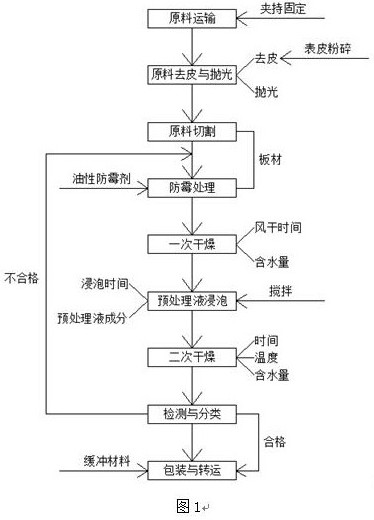

[0026] see figure 1 , the present invention provides a technical solution: a raw material pretreatment method for solid wood panels, comprising the following steps:

[0027] 1. Raw material transportation: The solid wood raw materials obtained after felling are transported to the designated pretreatment place through transportation equipment. During the transportation process, a series of measures are taken to clamp and fix the solid wood raw materials to prevent the solid wood raw materials from rolling and breaking during transportation. damaged by collision;

[0028] 2. Raw material peeling and polishing: After the solid wood raw material is transported to the designated pretreatment location, the solid wood raw material is peeled by special peeling equipment, so as to peel off the skin of the solid wood raw material. The surface of the solid wood raw material is polished to remove the remaining burrs after peeling;

[0029] For raw material peeling and polishing, the pee...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical solution: a raw material pretreatment method for solid wood panels, comprising the following steps:

[0044] 1. Raw material transportation: The solid wood raw materials obtained after felling are transported to the designated pretreatment place through transportation equipment. During the transportation process, a series of measures are taken to clamp and fix the solid wood raw materials to prevent the solid wood raw materials from rolling and breaking during transportation. damaged by collision;

[0045] 2. Raw material peeling and polishing: After the solid wood raw material is transported to the designated pretreatment location, the solid wood raw material is peeled by special peeling equipment, so as to peel off the skin of the solid wood raw material. The surface of the solid wood raw material is polished to remove the remaining burrs after peeling;

[0046] For raw material peeling and polishing, the pee...

Embodiment 3

[0060] see figure 1 , the present invention provides a technical solution: a raw material pretreatment method for solid wood panels, comprising the following steps:

[0061] 1. Raw material transportation: The solid wood raw materials obtained after felling are transported to the designated pretreatment place through transportation equipment. During the transportation process, a series of measures are taken to clamp and fix the solid wood raw materials to prevent the solid wood raw materials from rolling and breaking during transportation. damaged by collision;

[0062] 2. Raw material peeling and polishing: After the solid wood raw material is transported to the designated pretreatment location, the solid wood raw material is peeled by special peeling equipment, so as to peel off the skin of the solid wood raw material. The surface of the solid wood raw material is polished to remove the remaining burrs after peeling;

[0063] For raw material peeling and polishing, the pee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com