Differential case drilling clamp

A technology of differential case and drilling jig, which is applied in the direction of clamping, manufacturing tools, supports, etc., which can solve the problems of complex jig structure and inability to eliminate the press fit gap, and achieve the effect of reducing labor intensity and working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

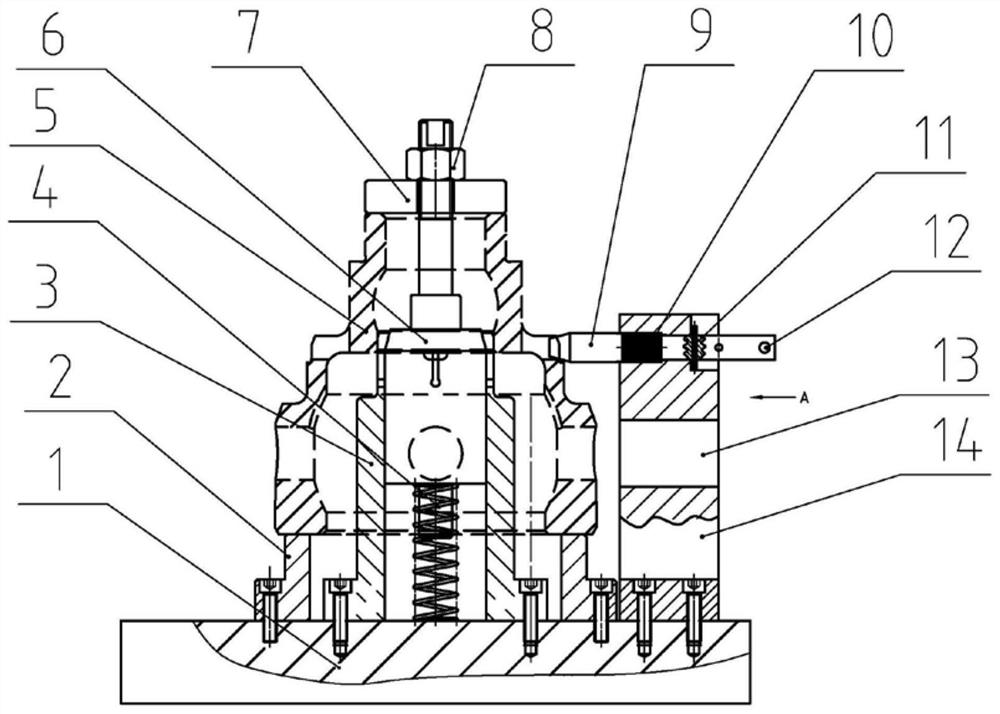

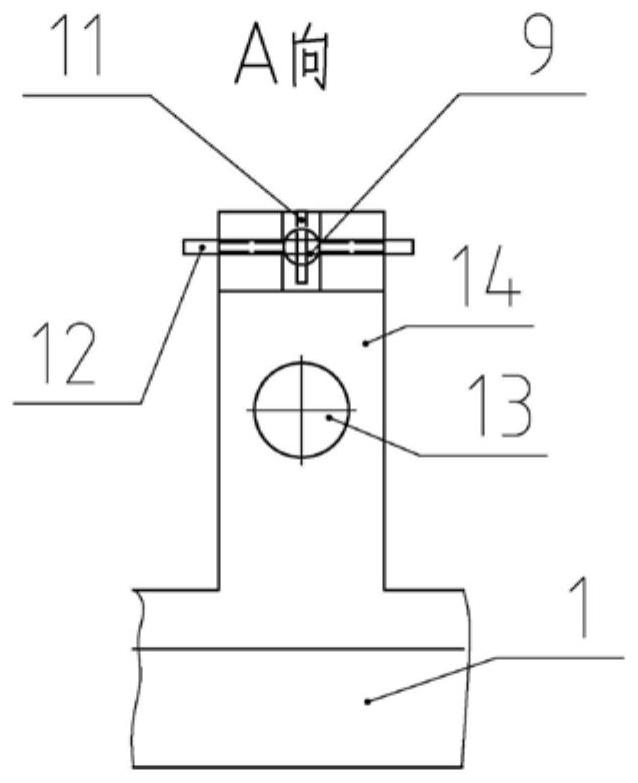

[0023] Such as figure 1 As shown in ~3, the present invention provides a differential case drilling jig, which is provided with a base 1, a support seat 2, an expansion spring 3, a compression spring A4, a differential case 5, an expansion cone 6, and an opening ring 7 , Compression nut 8, positioning pin 9, compression spring B10, stop pin 11, handle 12, let the knife hole 13, positioning seat 14.

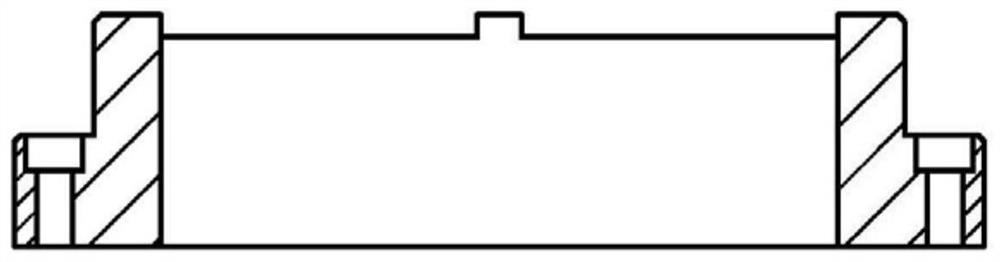

[0024] The base 1 is a square body, on which there are screw holes for installing various parts. The expansion spring 3 is provided with a sleeve with a through-hole flange on the lower part, and the inner cone with 3-4 open slots is provided on the upper part. The expansion cone 6 is the upper part. Set thread, the lower part is equipped with outer cone and stepped cylinder tie rod, the expansion cone 6 is installed in the expansion spring 3 hole, the lower end is set with the compression spring A4, and fixed with the corresponding screw hole of the base 1 through the flange hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com