Scheduling method based on multi-variety mixed flow assembly mode

A multi-variety and mixed-flow technology, applied in the field of enterprise assembly and production scheduling, can solve the problems of increasing the difficulty of production task scheduling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Next, the technical solutions in the embodiments of the present invention will be clearly and completely described, and the described embodiments are merely, and not all embodiments are based on the embodiments of the present invention. EXEGITIONITURE TECHNICAL INVENTION In the art, in the art, all other embodiments obtained without paying creative labor are all scope of the present invention.

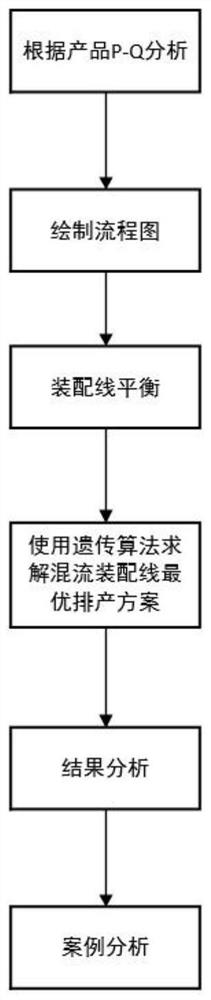

[0039] A method according to a multi-variety mixed flow assembly mode includes the following steps:

[0040] Step 1: Analyze the P-Q analysis

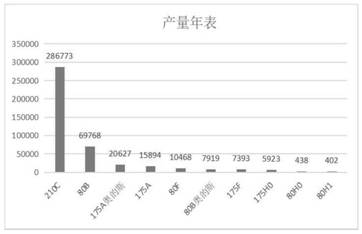

[0041] Collect information such as product types and annuality metrics such as a corporate elevator buffer assembly line, draw the annual output map of the assembly line, and find key products. like figure 2 As shown, an annual output map of the elevator buffer.

[0042] Step 2: Drawing flow chart

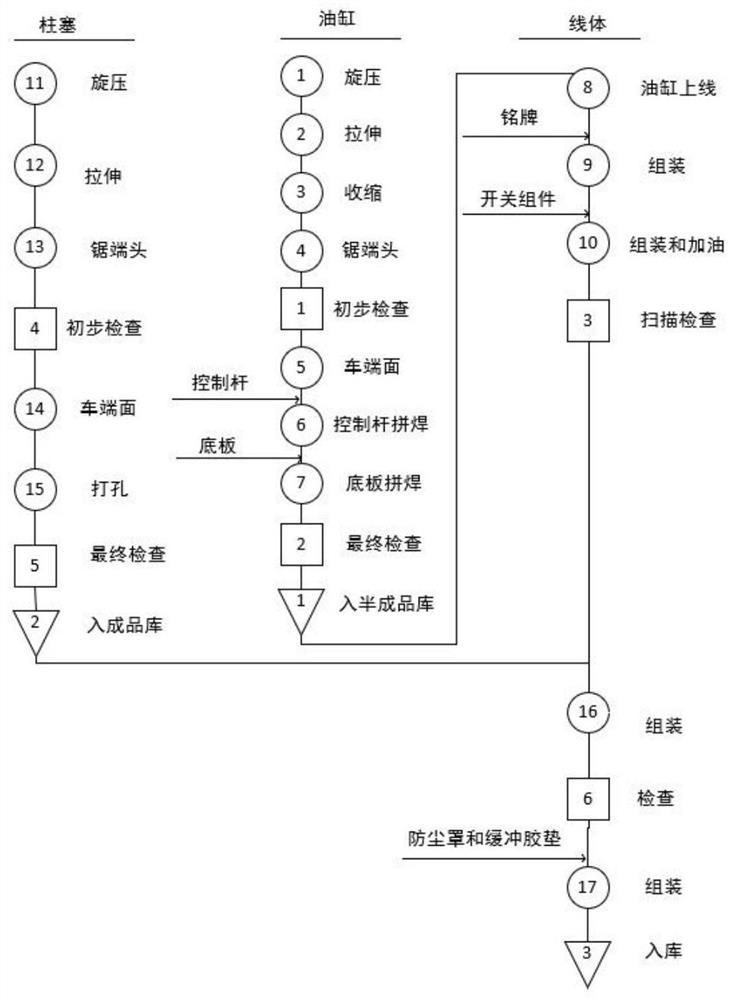

[0043] According to the step, it is known that the key product is a 210C buffer, clarifies the assembly process, personnel, time, required stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com