Quick remodeling mechanism for automobile part detection

A fast technology for auto parts, applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as limited service life of connecting parts, cumbersome operation steps, poor connection reliability of fixtures and testing equipment, etc. Achieve the effects of reasonable equipment structure design, fast and simple operation, and high efficiency of model change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

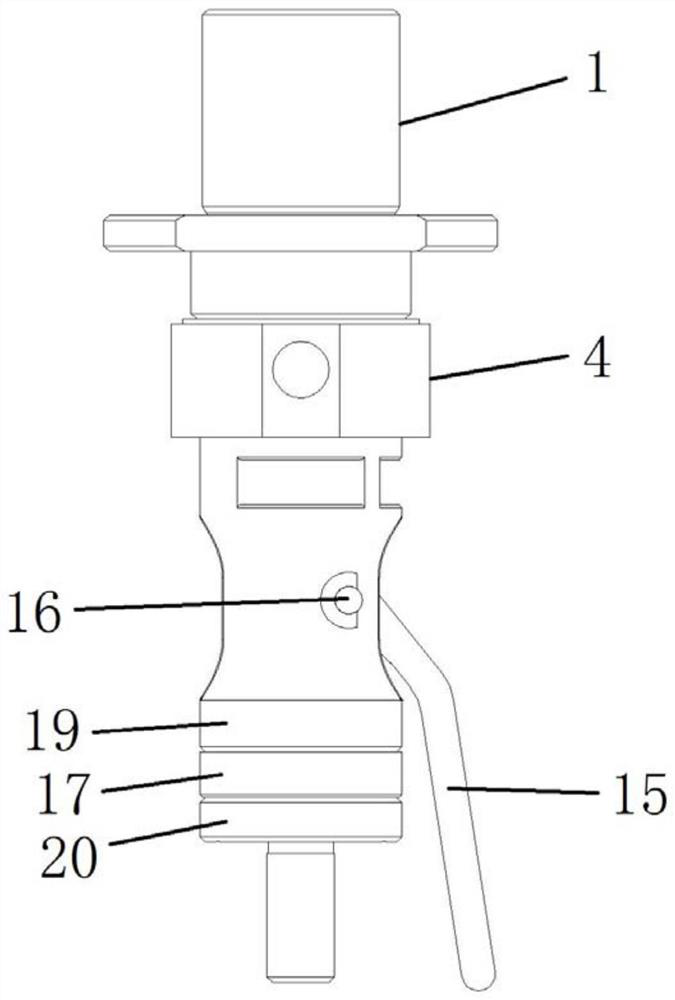

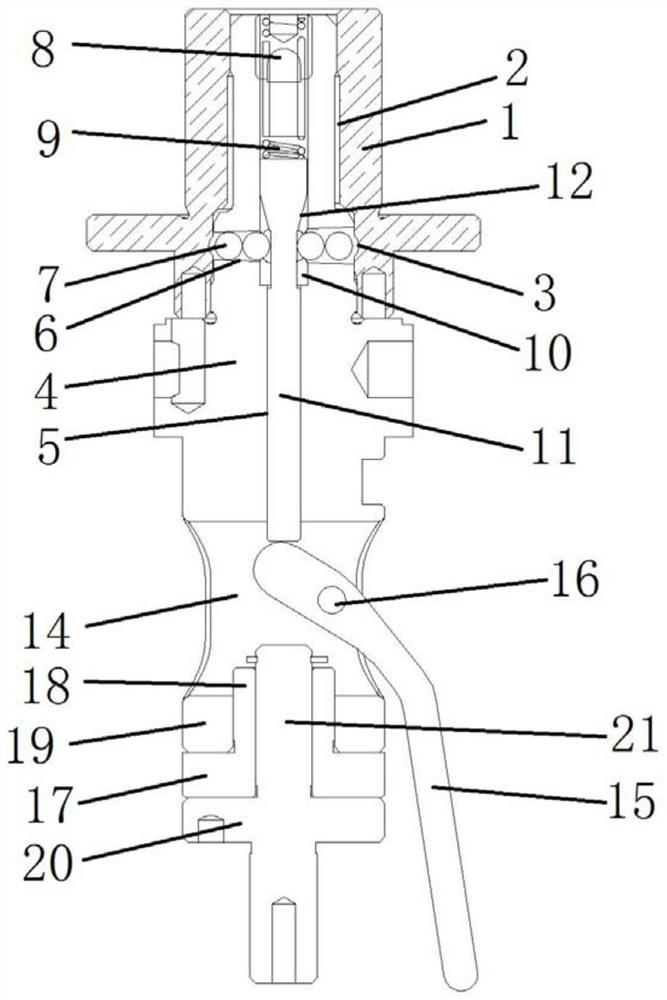

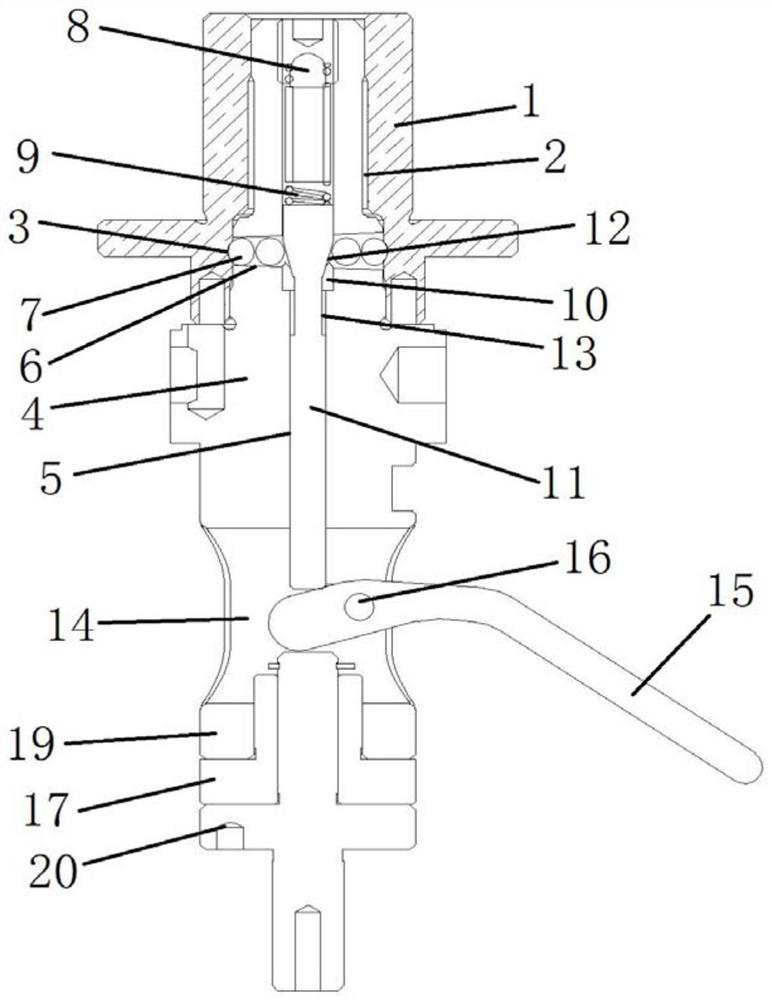

[0027] The embodiment of the present invention discloses a quick-change mechanism for auto parts detection, such as Figure 1 to Figure 6 As shown, it includes a fixed base 1, a guide sleeve 4, a beveled thimble 11, a positioning ball 7, a lifting drive device, a base 17 and a connecting shaft 20. The inside of the fixed base 1 is provided with a step-shaped installation hole 2 that penetrates along the axial direction, and the guide sleeve 4. The upper part is movably inserted into the installation hole 2, and the shape of the upper part of the guide sleeve 4 matches the shape of the installation hole 2. By setting the step-shaped installation hole 2, the guide sleeve 4 is limited when it is installed in the fixed seat 1. The side wall of the installation hole 2 is provided with an arc-shaped groove 3 along the circumferential direction, and the inside of the guide sleeve 4 is provided with a guide hole 5 along the axial direction. In the guide hole 5, a beveled thimble 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com