A crane rig for lifting large tubular weights

A crane cable and tubular technology, applied in the field of crane rigging, can solve the problems of unfavorable weight center balance and low safety, and achieve the effects of high practicability, labor reduction and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

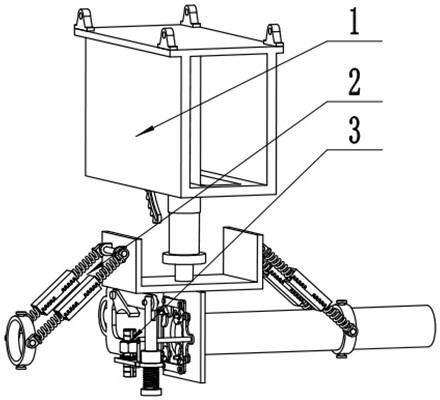

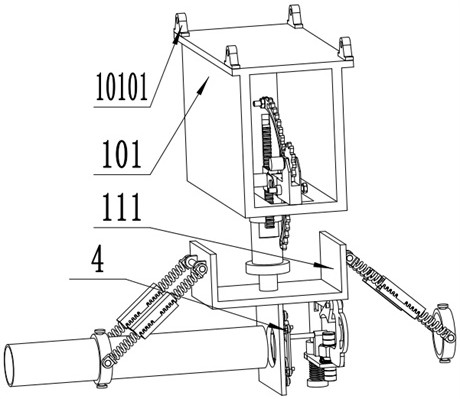

[0024] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 The shown crane rigging for lifting large tubular weights includes a steering mechanism 1 , a positioning mechanism 2 , an auxiliary fixing mechanism 3 , and a fixing mechanism 4 .

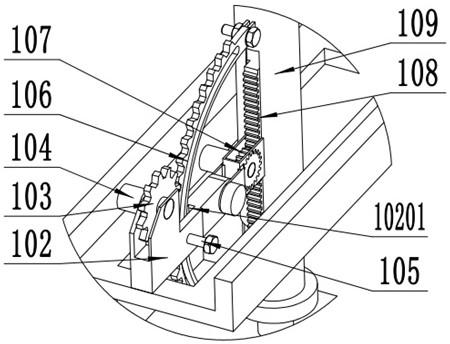

[0025] Such as figure 2 , 3 , the steering mechanism 1 shown in 4, the lifting lug 10101 is fixedly installed on the top of the hanging box 101, the lifting lug 10101 is convenient for the lock to be fixed on various cranes, the support 102 is fixed on the hanging box 101, and the steering gear 103 is rotated and installed On the bearing 102, the steering motor 104 is fixedly installed on the bearing 102, the steering gear 103 is fixedly installed on the output shaft of the steering motor 104, the steering motor 104 drives the steering gear 103 to rotate, and the arc gear 106 is slidably installed On the square hole 10201, the limit pin 105 is fixedly installed on the support 102, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com