Anti-crash seat adopting extruded tube type energy absorber

An extruded tube and anti-crash technology, which is applied to the arrangement of seats, aircraft parts, support/fixation devices, etc., can solve the problems of complex structure and manufacturing process, and low applicability of energy absorbers and the main frame of passenger seats. , to achieve the effect of simple structure, high reliability and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below by means of the accompanying drawings and examples.

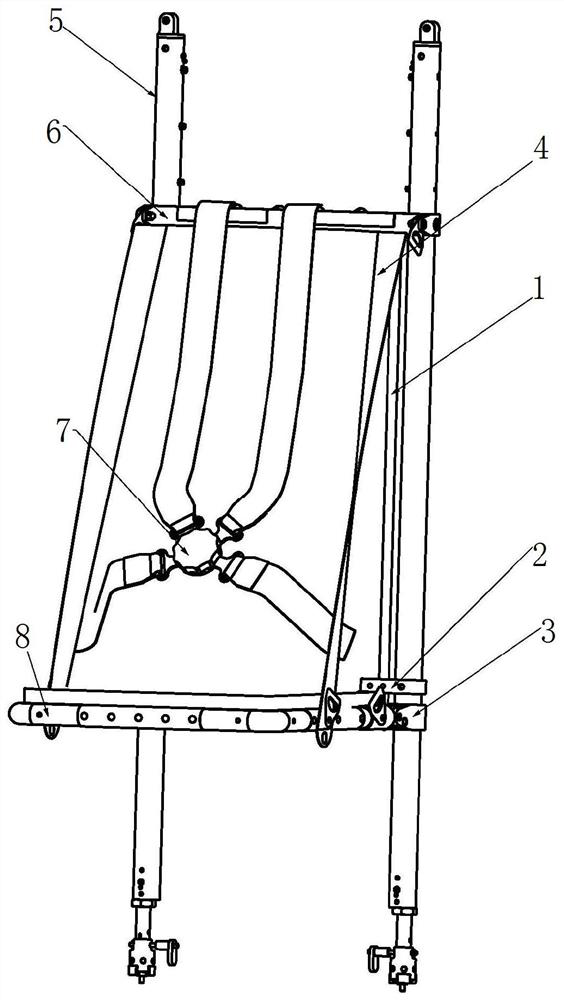

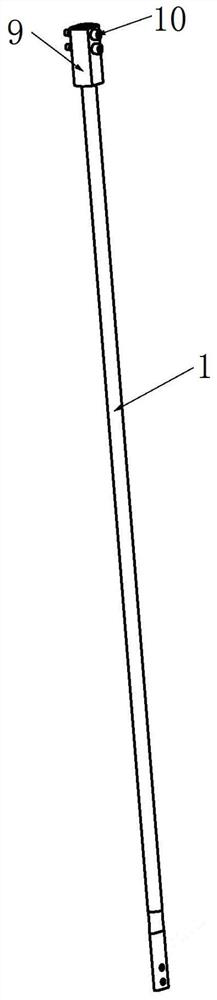

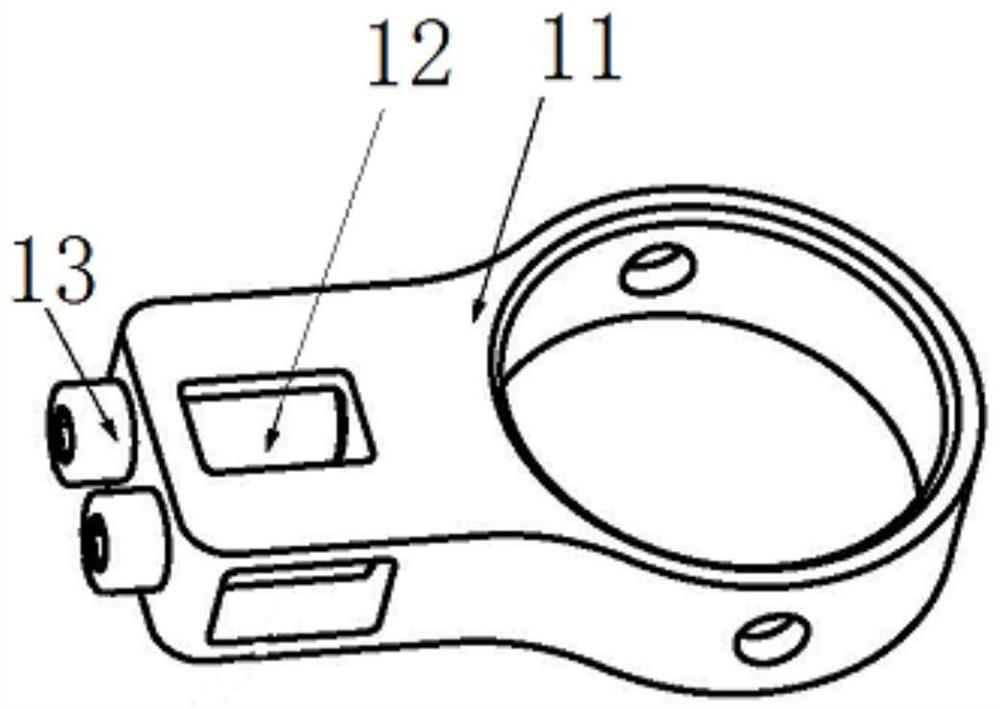

[0024] Such as Figure 1 to Figure 6 As shown, an anti-crash seat using an extruded tube type energy absorber includes a seat column 5, an upper cross bar 6, a lower cross bar 3, an extruded tube 1, a seat plate assembly 8 and an extruded seat assembly 2 , the seat column 5 is fixedly installed as the main frame of the seat, the upper cross bar 6 and the lower cross bar 3 are slidably fitted on the seat column 5 on both sides at both ends, and the extrusion tube 1 and the seat column 5 Parallel and the upper and lower ends are respectively connected and fixed with the upper cross bar 6 and the lower cross bar 3, the seat plate assembly 8 is installed and fixed on the lower cross bar 3, the extruded seat assembly 2 is installed and fixed on the seat column 5, and the extruded seat assembly 2 includes A pair of squeeze rollers side by side with a gap left. The lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com