Spraying device facilitating adjustment of powder supply amount for cast iron pipeline

A spraying device and pipeline technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve problems such as difficulty in grasping the amount of powder sprayed, uneven powder spraying, powder waste, etc., to save manpower and material resources, comprehensive powder spraying, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

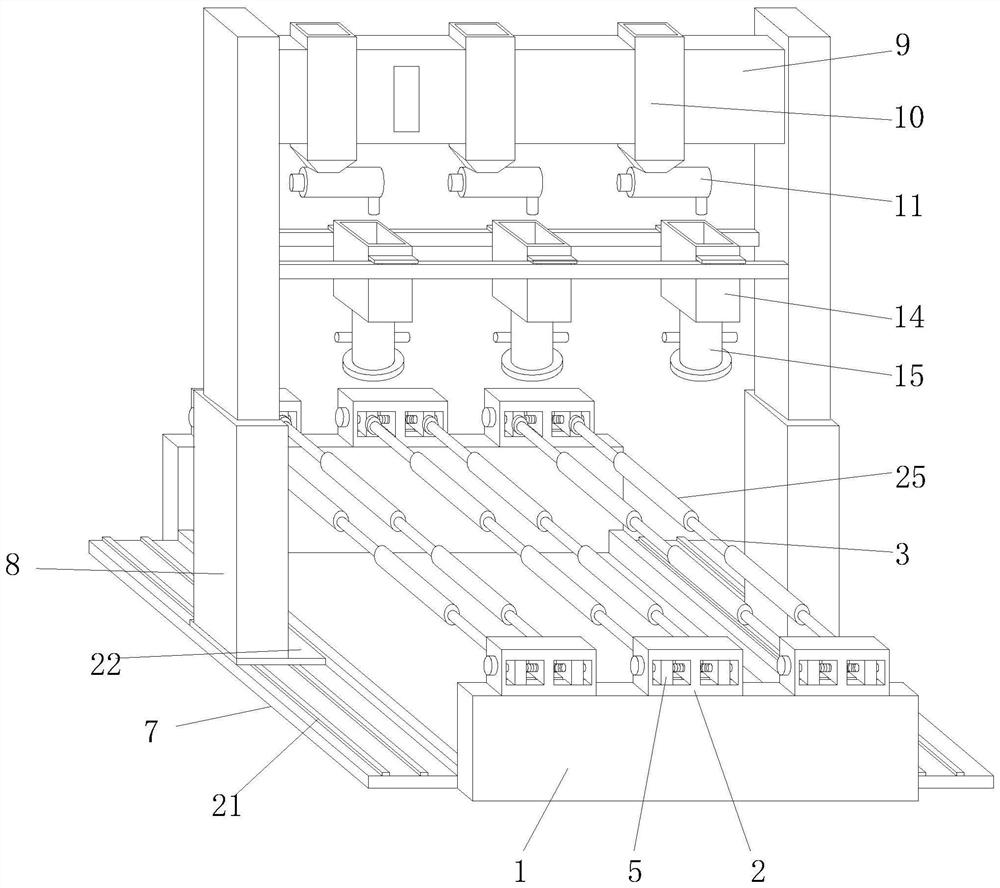

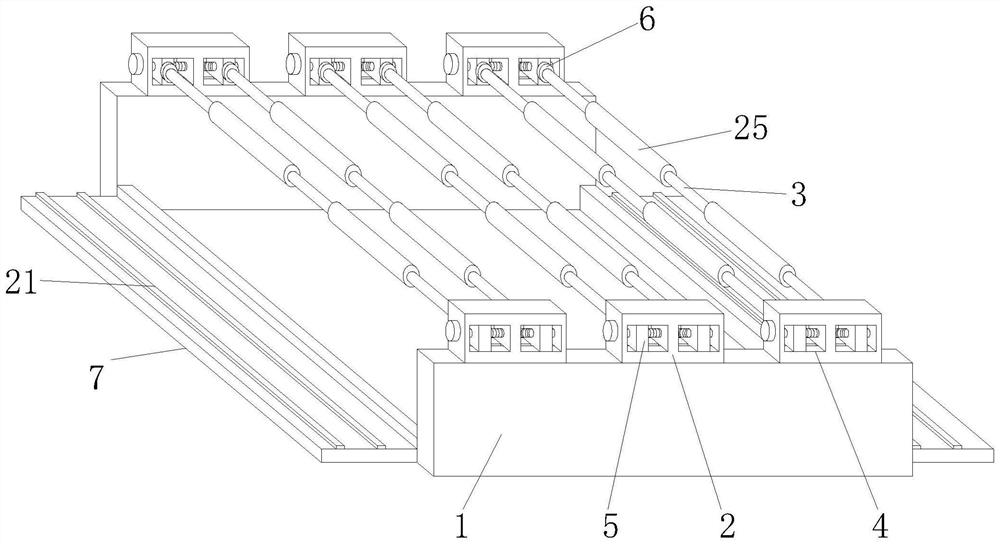

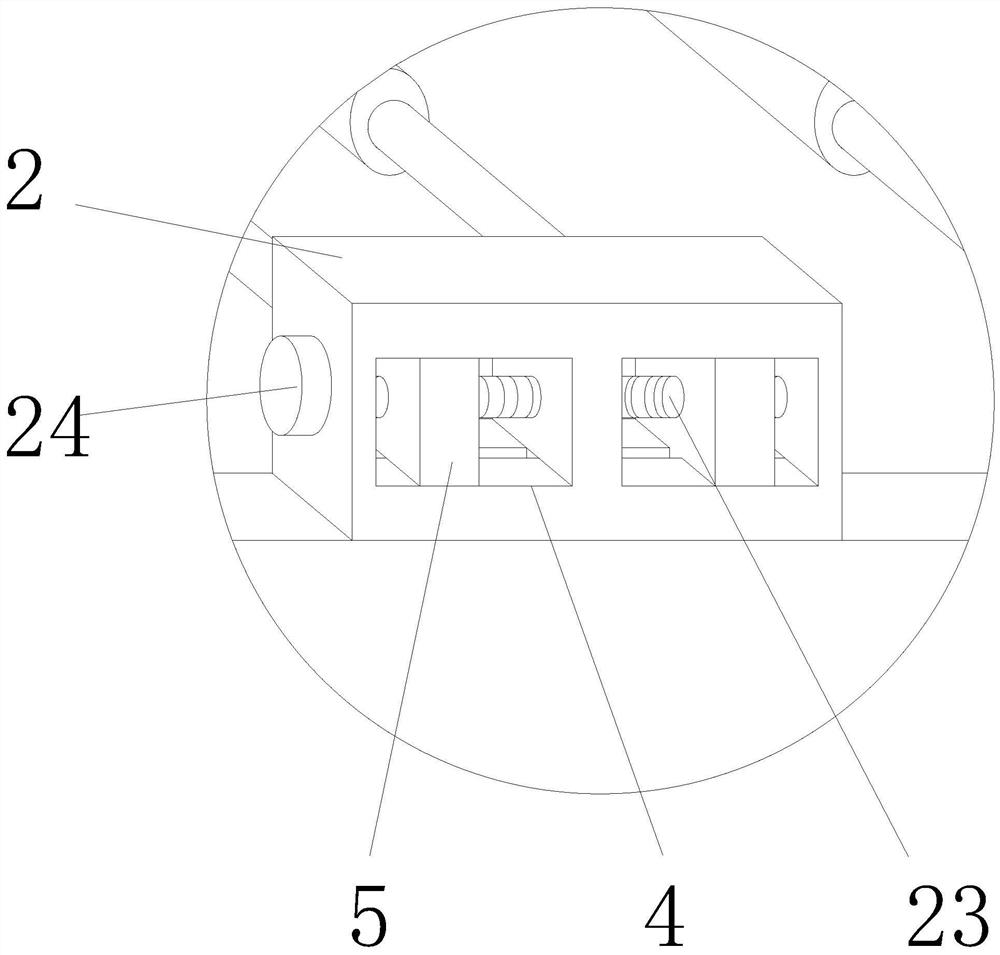

[0027] according to figure 1 , 2 , 3, 4, and 5, this embodiment proposes a spraying device for cast iron pipelines that is convenient for adjusting the powder supply, including a rolling assembly and a powder spraying assembly, and the powder spraying assembly includes a frame 1 and is located on the frame 1 rolling unit, the rolling unit includes the mounting block 2 and the rotating shaft 3 at the front and rear ends, both sides of the mounting block 2 are provided with chute 4, and the insides of the two sets of chute 4 are movably installed by the drive part There is a slider 5, the rotating shaft 3 is installed between the sliders 5 at the front and rear ends, and the slider 5 at the rear end is provided with a first motor 6, and the output end of the first motor 6 is connected to the rotating shaft 3 connected, the two sets of rotating shafts 3 in the rolling unit rotate synchronously and in the same direction;

[0028] Both sides of the frame 1 are provided with a sup...

Embodiment 2

[0036] according to figure 1 , 2, 4, the present embodiment proposes a spraying device for a cast iron pipeline that is convenient for adjusting the powder supply, including a rolling assembly and a powder spraying assembly, and the powder spraying assembly includes a frame 1 and a rolling unit arranged on the frame 1, The rolling unit includes a mounting block 2 and a rotating shaft 3 at the front and rear ends. Both sides of the mounting block 2 are provided with chute 4, and the insides of the two sets of chute 4 are movably installed with sliders 5 through the driving part. , the rotating shaft 3 is rotatably installed between the sliders 5 at the front and rear ends, and the slider 5 at the rear end is provided with a first motor 6, the output end of the first motor 6 is connected to the rotating shaft 3, and the The two groups of rotating shafts 3 in the rolling unit rotate synchronously and in the same direction;

[0037] Both sides of the frame 1 are provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com