Preparation process of novel synbiotic bean dreg fermented beverage

A fermented beverage and preparation technology, which is applied to the functions and applications of food ingredients, and food ingredients as odor improvers, etc. It can solve the problems of bad taste of bean dregs and heavy beany smell, so as to optimize the product flavor and pleasant aroma , high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

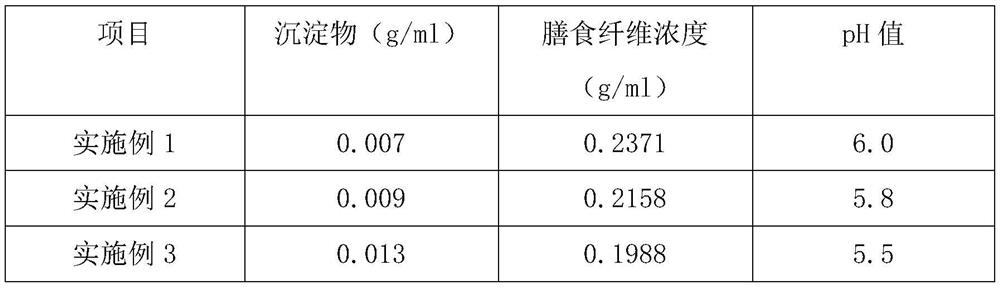

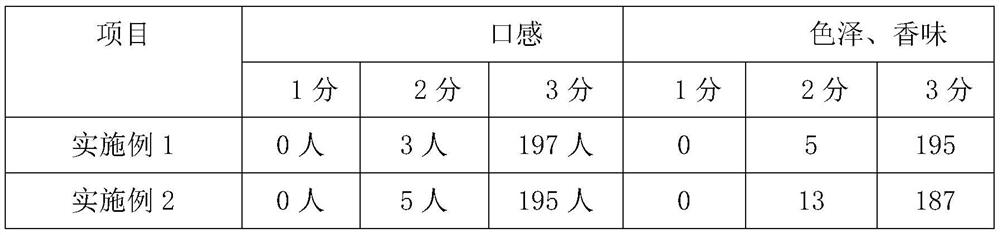

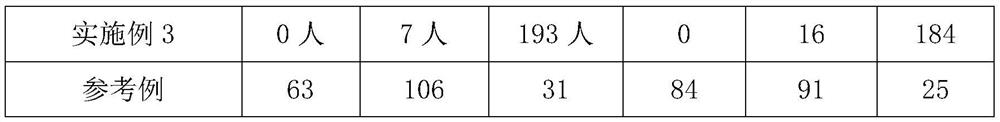

Embodiment 1

[0028] In the embodiment of the present invention, a novel synbiotic bean dregs fermented beverage includes the following percentage materials:

[0029] Okara powder 4%, white sugar 8%, citric acid 0.05%, vitamin C 1%, stabilizer 0.2%, pineapple essence 0.01%, water.

[0030] As a further solution of the present invention: a preparation process for a novel synbiotic bean dregs fermented beverage comprises the steps:

[0031] Step 1. Dissolving and homogenizing: mix water, bean dregs powder, white sugar, citric acid, vitamins, stabilizers, and pineapple essence according to the ratio of material to water ratio of 1:12, and put them into a homogenizer for homogenization treatment to obtain Mixture;

[0032] Step 2, sterilization: put the homogenized mixture into an autoclave for sterilization;

[0033] Step 3, cooling, inoculation, and fermentation: cooling the sterilized mixture to 37°C, adding a starter, and fermenting in a thermostat at 37°C for 12 hours to obtain a ferment...

Embodiment 2

[0044] A novel synbiotic soybean dregs fermented beverage comprises the following percentages of materials:

[0045] Okara powder 5%, white sugar 9%, citric acid 0.10%, vitamin C 1%, stabilizer 0.2%, pineapple essence 0.01%, water.

[0046] As a further solution of the present invention: a preparation process for a novel synbiotic bean dregs fermented beverage comprises the steps:

[0047] Step 1. Dissolving and homogenizing: mix water, bean dregs powder, white sugar, citric acid, vitamins, stabilizers, and pineapple essence according to the ratio of material to water ratio of 1:14, and put them into a homogenizer for homogenization treatment to obtain Mixture;

[0048] Step 2, sterilization: put the homogenized mixture into an autoclave for sterilization;

[0049] Step 3, cooling, inoculation, and fermentation: cooling the sterilized mixture to 37°C, adding a starter, and fermenting in a thermostat at 37°C for 18 hours to obtain a fermented beverage containing bean dregs; ...

Embodiment 3

[0060] A novel synbiotic soybean dregs fermented beverage comprises the following percentages of materials:

[0061] Okara powder 6%, white sugar 10%, citric acid 0.15%, vitamin C 1%, stabilizer 0.2%, pineapple essence 0.01%, water.

[0062] As a further solution of the present invention: a preparation process for a novel synbiotic bean dregs fermented beverage comprises the steps:

[0063] Step 1. Dissolving and homogenizing: mix water, bean dregs powder, white sugar, citric acid, vitamins, stabilizers, and pineapple essence according to the ratio of material to water 1:15, and put them into a homogenizer for homogenization treatment to obtain Mixture;

[0064] Step 2, sterilization: put the homogenized mixture into an autoclave for sterilization;

[0065] Step 3, cooling, inoculation, and fermentation: cooling the sterilized mixture to 37°C, adding a starter, and fermenting in a thermostat at 37°C for 24 hours to obtain a fermented beverage containing bean dregs;

[0066]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com