Display substrate, preparation method thereof and display device

A display substrate and display area technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of occupying a large area, poor anti-crack extension effect, unfavorable narrow frame, etc., to prevent cracking , Improve the effect of poor water vapor intrusion and ensure a flat trend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

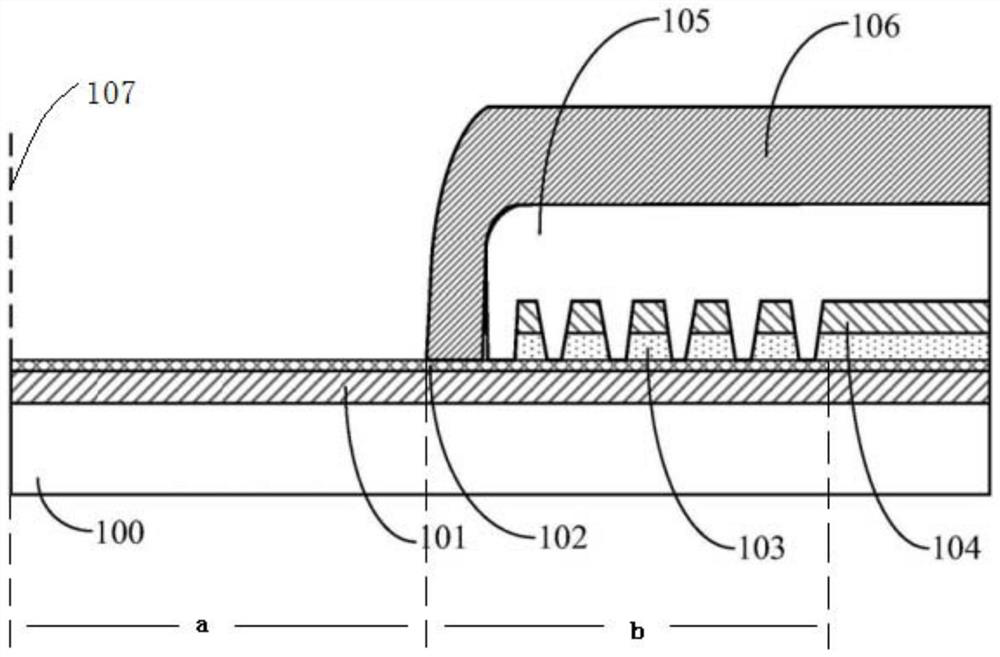

Examples

preparation example Construction

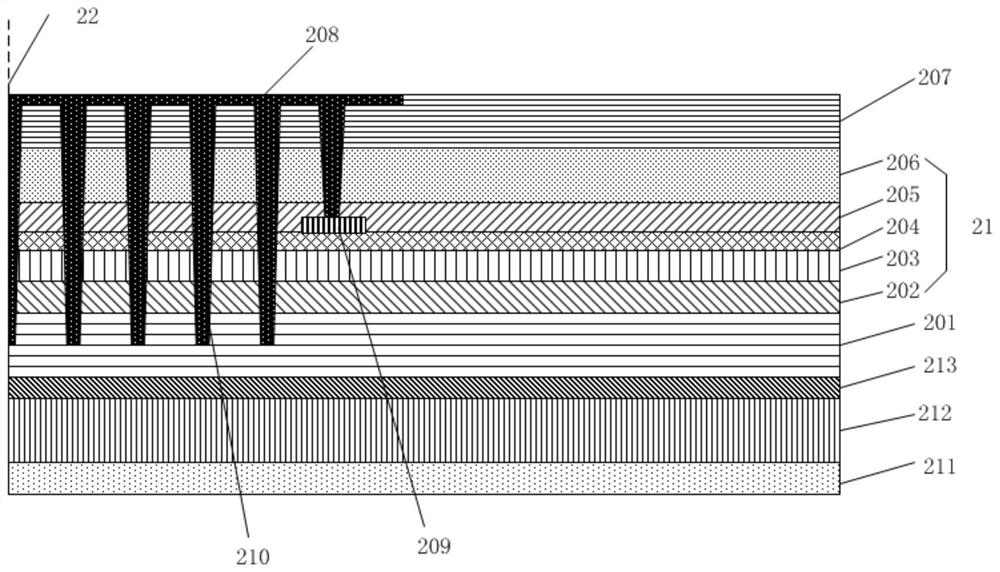

[0108] In some embodiments, the preparation method also includes:

[0109] Step S201, forming a touch layer on the side of the film layer unit away from the substrate;

[0110] Step S202 , forming a second protection layer on a side of the touch layer away from the substrate. Wherein, the second protective layer 207 is used to protect the touch layer and prevent the touch layer from being damaged.

[0111] In some embodiments, the first protection layer is located in the edge protection area; the second protection layer includes a first sub-protection area located in the edge protection area and a second sub-protection area located in the display area The first sub-protection area is disposed between the film layer unit and the first protection layer, and the end of the dam structure away from the base penetrates through the first sub-protection area. The thickness of the first protective layer is less than 1 μm.

[0112] In this embodiment, before step S103 , a touch layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com