Optimization method of contact track and transmission error of spiral bevel gear based on installation misalignment

A technology of spiral bevel gear and transmission error, which is applied in the field of optimization of spiral bevel gear contact track and transmission error based on installation misalignment, can solve the problems of non-optimal gear meshing performance and failure to pay attention to the optimal installation misalignment value, etc., to achieve Excellent bearing contact performance, reduce vibration and noise, and avoid edge contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

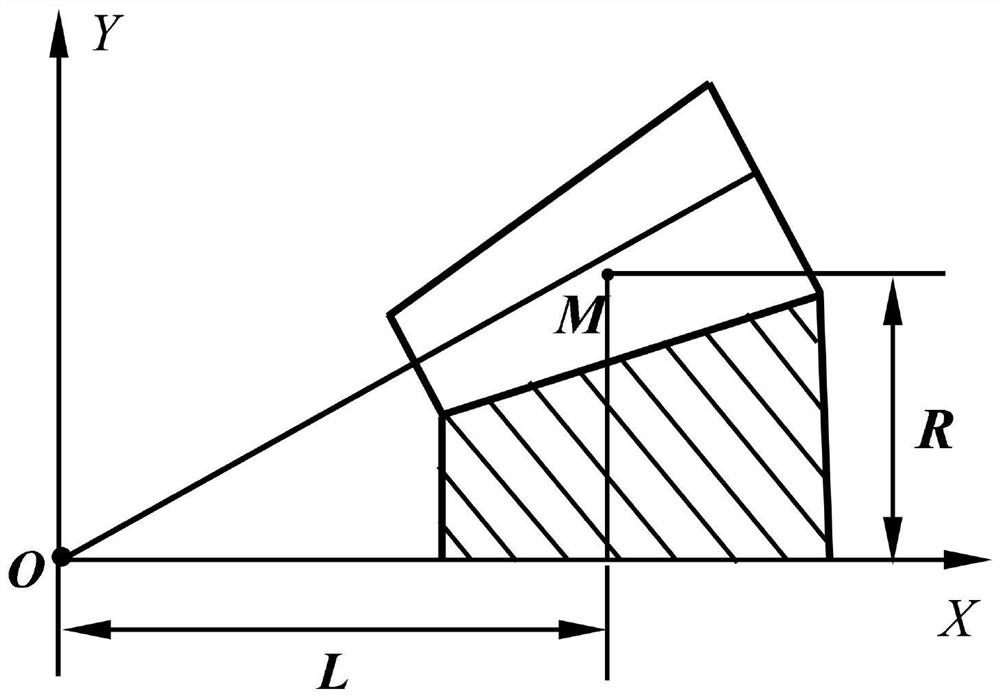

[0055]

[0058]

[0059]

[0062] n

[0063] n

[0065]

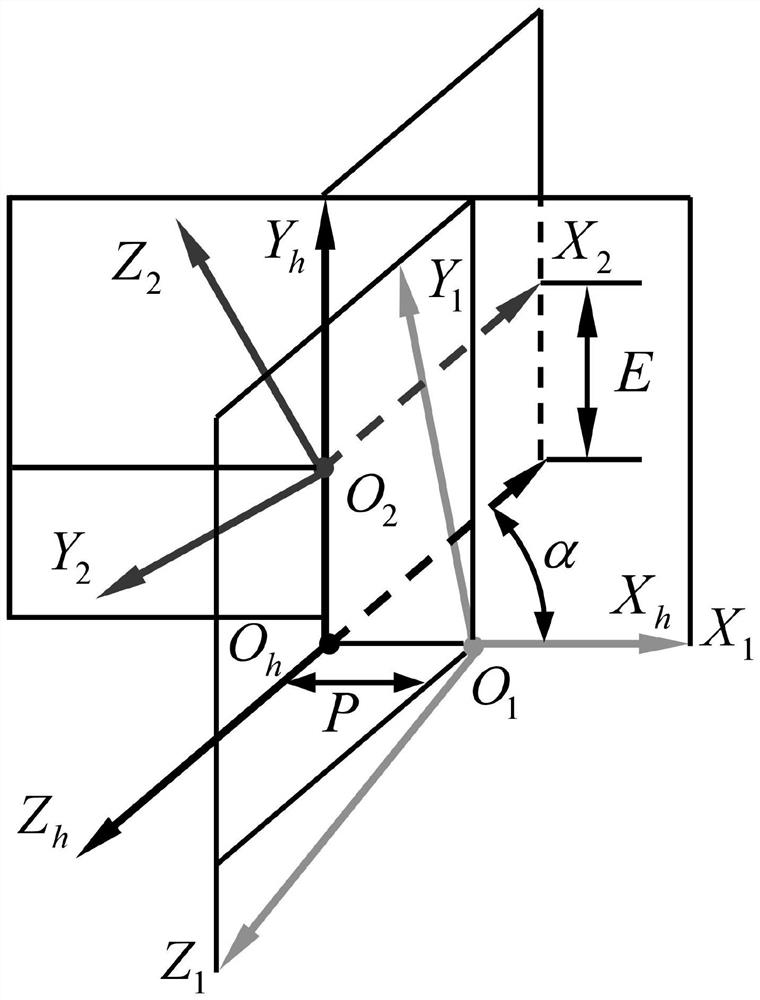

[0070]

[0071]

[0073]

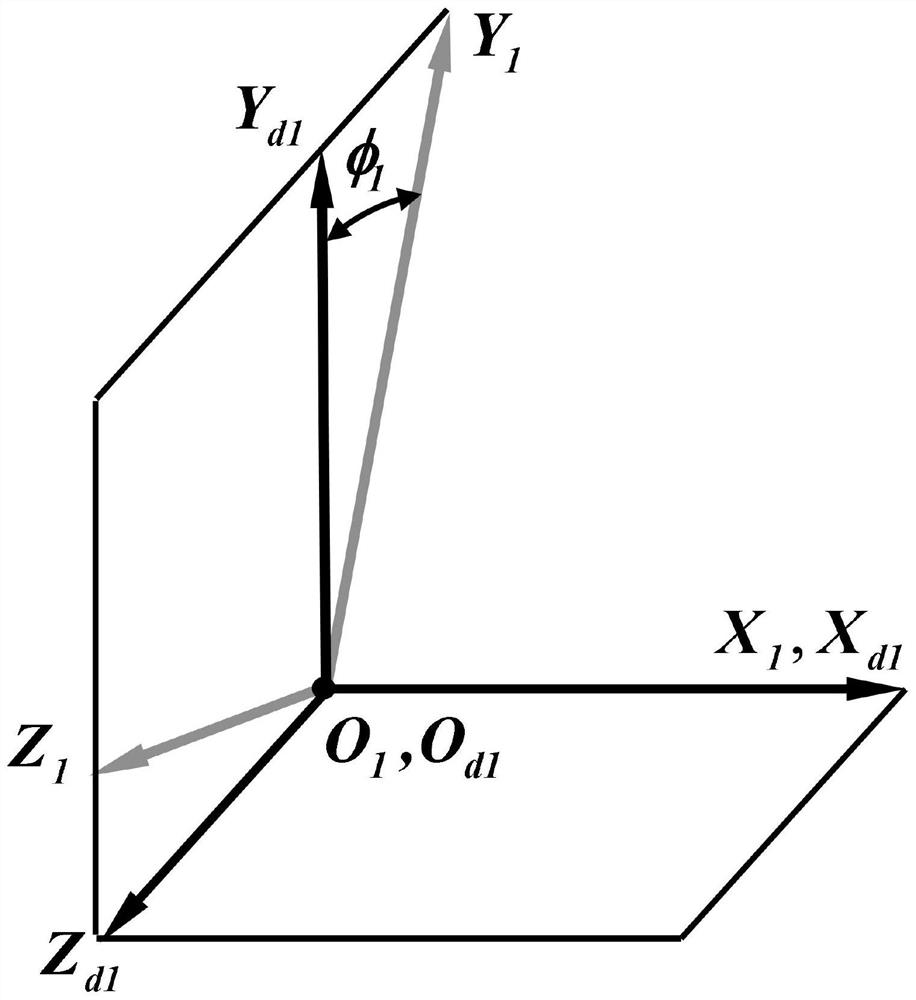

[0074]

[0075]

[0076]

[0078]

[0079]

[0080] Here is obtained by removing the last row and the last column.

[0082]

[0083]

[0086]

[0089]

[0096]

[0098] f

[0099] f

[0100] 3.2 Optimization objective function

[0103]

[0105]

[0106]

[0110] According to the optimization adjustment function model and the defined characteristic parameters, an optimal adjustment objective function can be established. For connecting

[0111]

[0114] f

[0119]

[0120]

[0121] The spiral bevel gear pair processed by the principle of a pair of flat-top shape-forming wheels is the research object. See Table 1 for gear design parameters.

[0122] According to the theoretical installation adjustment value of the gear pair in section 2.1, P is -0.5751, E is 0.4979, and the installation is dislocated

[0125]

[0128]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com