Spiral bevel gear contact track and transmission error optimization method based on installation dislocation

A technology of spiral bevel gear and transmission error, applied in the field of spiral bevel gear contact trajectory and transmission error optimization based on installation misalignment, can solve the problems of non-optimal gear meshing performance, not paying attention to the optimal installation dislocation value, etc. Excellent load bearing contact performance, reducing vibration and noise, and avoiding the effect of edge contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Get the theoretical installation adjustment value:

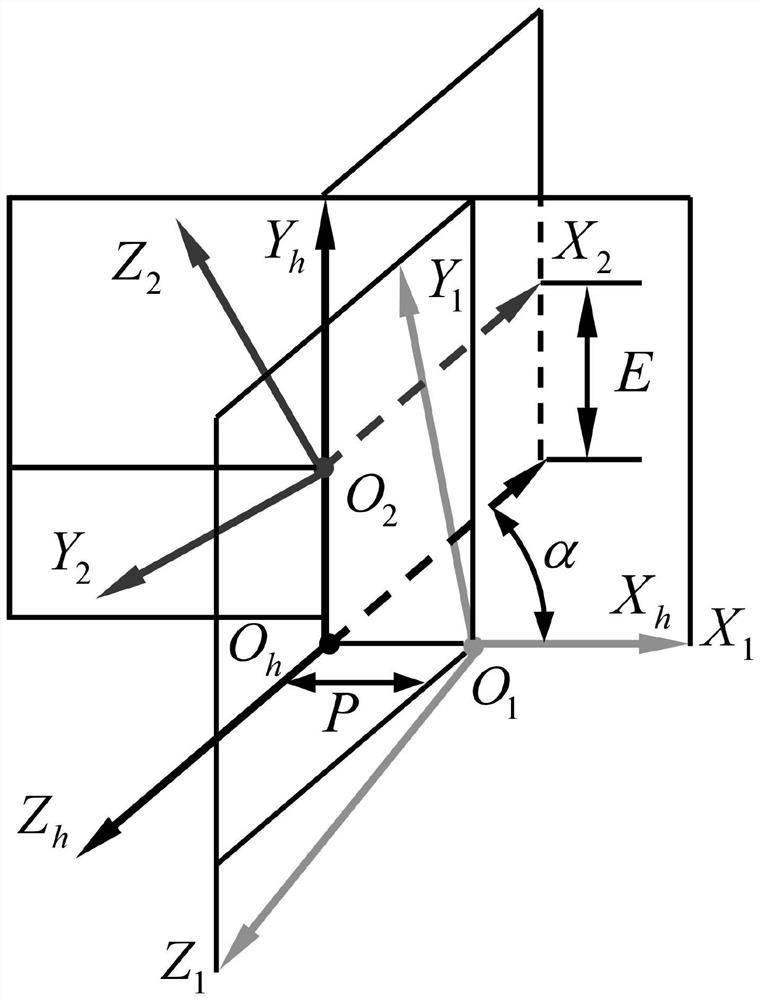

[0053] The ideal gear pair installation is to assemble the processed large and small wheels according to the designed shaft angle α and the theoretical installation adjustment values E, P, and G. Among them, E is the adjustment amount of the offset distance of the large wheel, P is the adjustment amount of the installation distance of the small wheel, and G is the adjustment amount of the installation adjustment distance of the large wheel. However, there are installation misalignments Δα, ΔE, ΔP, ΔG in actual assembly, so that the gears are installed under the misaligned installation values of α+Δα, E+ΔE, P+ΔP, G+ΔG.

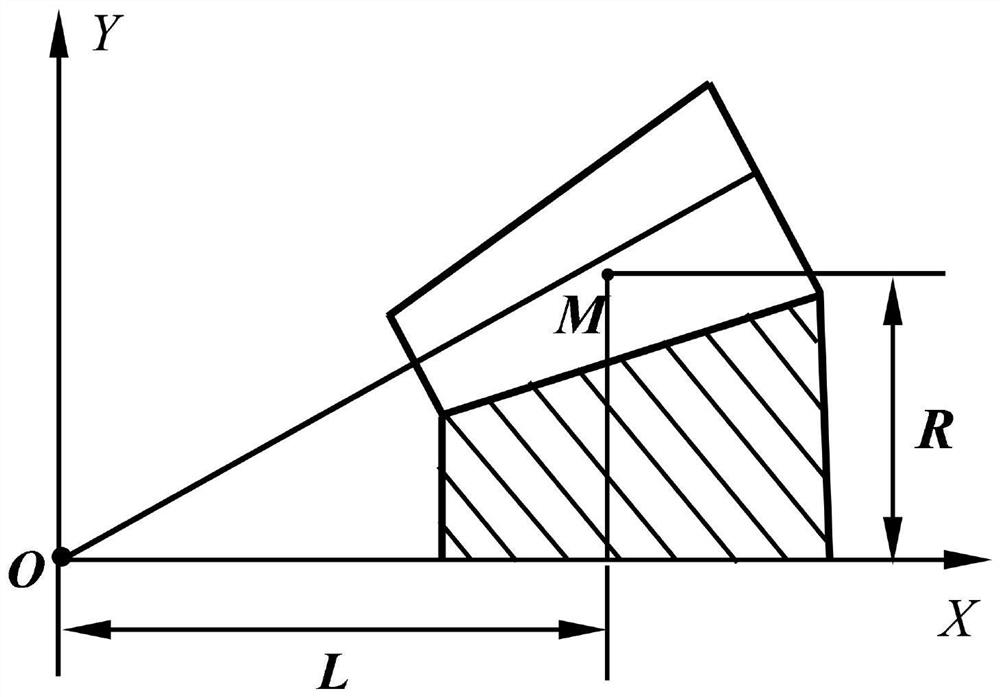

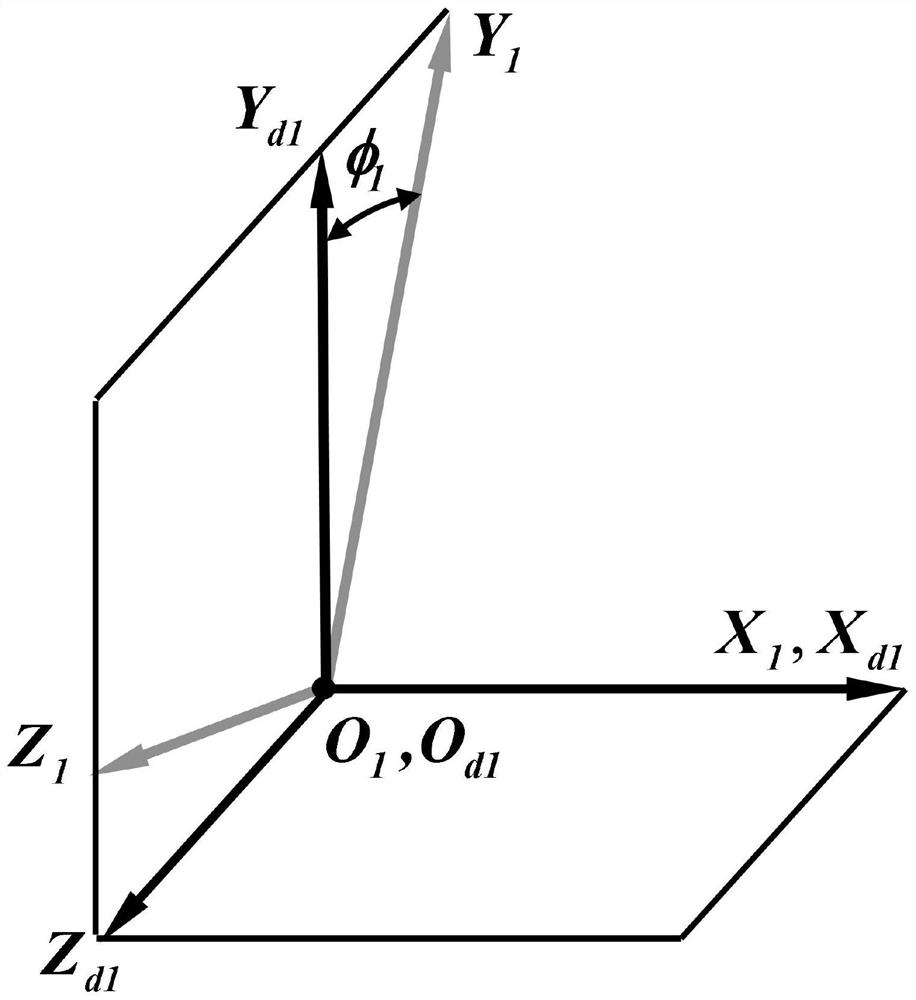

[0054] In the installation and adjustment of spiral bevel gears, G is usually set to 0, and the gear pair is in a proper installation position by changing the two values of E and P. Under the proper installation position, the large and small wheels rotate around their own axes respectively φ 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com