Pre-embedded pipe for heating pipe network with curved protection structure

A technology for protecting structure and heating pipe network, applied in the field of pre-buried pipes for heating, can solve the problems of difficulty in repair and high repair cost, leakage of hot steam and hot water, failure of heating pipes, etc. and hot water leakage, increase bond strength and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

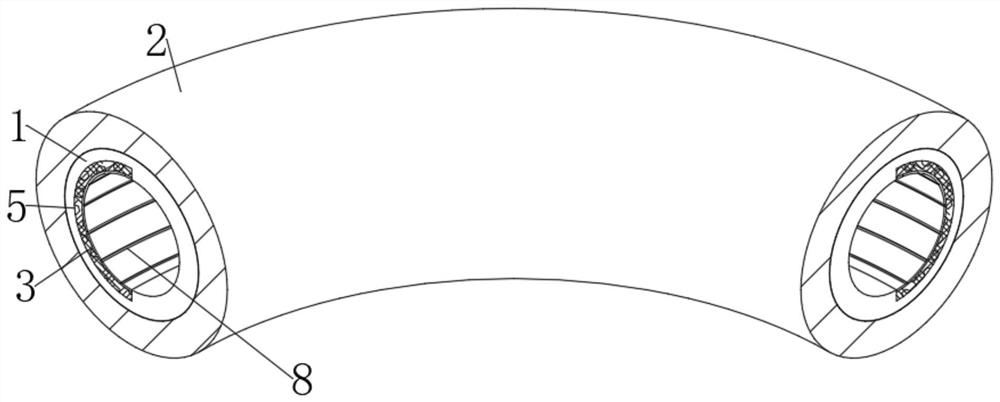

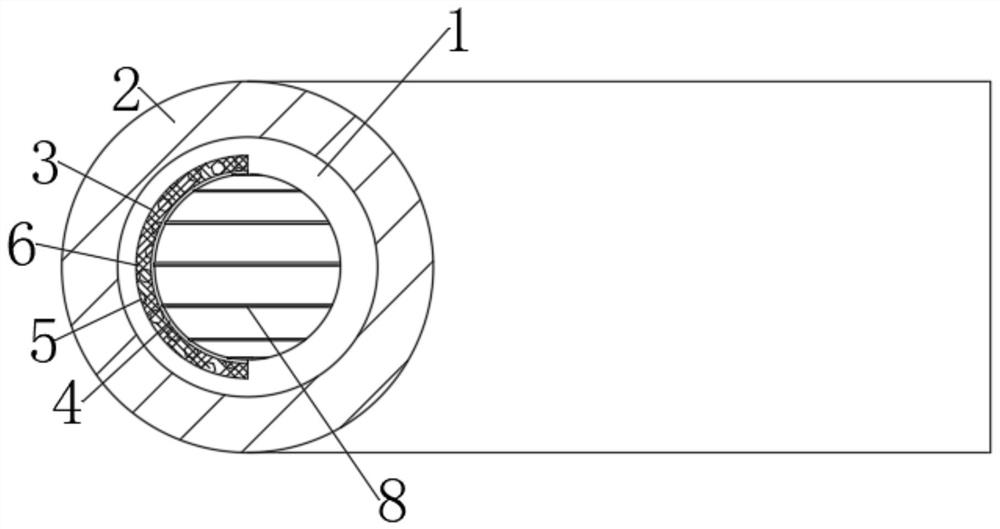

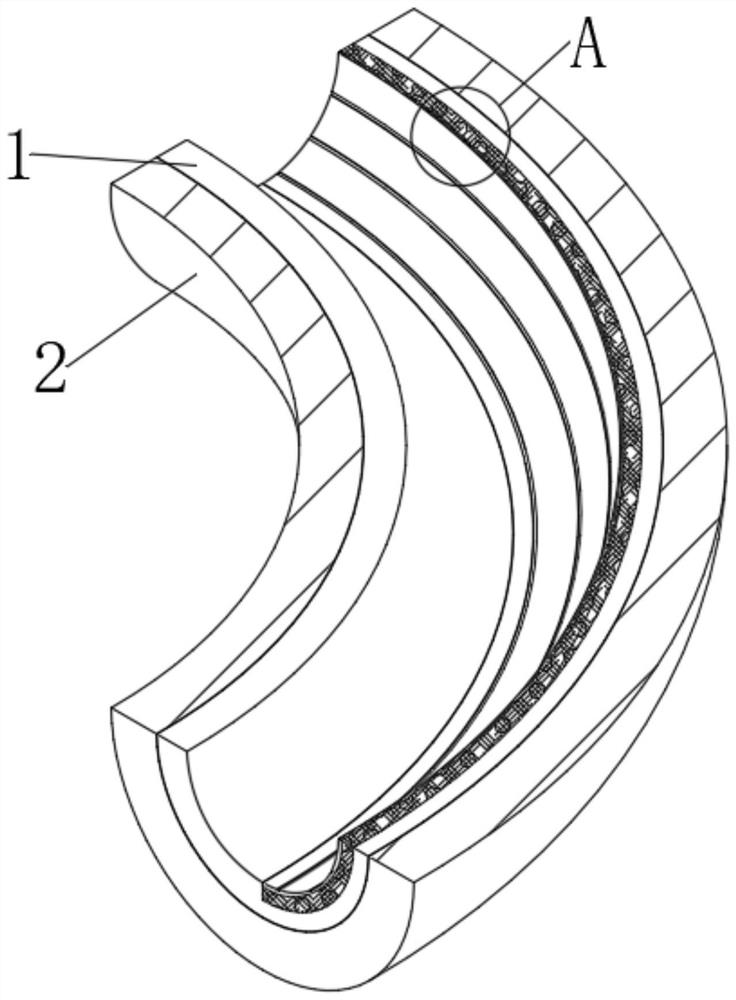

[0038] see Figure 1-5 and Figure 8 , a pre-embedded pipe for a heating pipe network with a curved protection structure, comprising a metal heating pipe 1, the outer side of the metal heating pipe 1 is fixedly connected with an insulating layer 2 that matches itself, and the metal heating pipe 1 is fixed on the outside. A buffer groove 3 is excavated. The buffer groove 3 is located on the outer wall of the bend of the metal heating pipe 1. The notch of the buffer groove 3 is fixedly connected with a buffer rubber pad 4 that matches itself. A plurality of filling balls are placed in the buffer groove 3. 5. The protective grid clusters 6 are fixedly connected to the plurality of filling balls 5. The filling balls 5 include elastic rubber balls 501. Prefabricated holes 502 are drilled on the elastic rubber balls 501. The arc length of the prefabricated holes 502 does not exceed the length of the elastic rubber balls 501. A quarter, the prefabricated hole 502 is located at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com