A scalable multi-position construction building platform

A construction platform and platform technology, applied in the direction of construction, building structure, scaffolding accessories, etc., can solve the problems of not being able to meet the requirements of rapid construction, consuming manpower and material resources, inconvenient movement, etc., and achieve high installation level, easy operation, and lifting work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

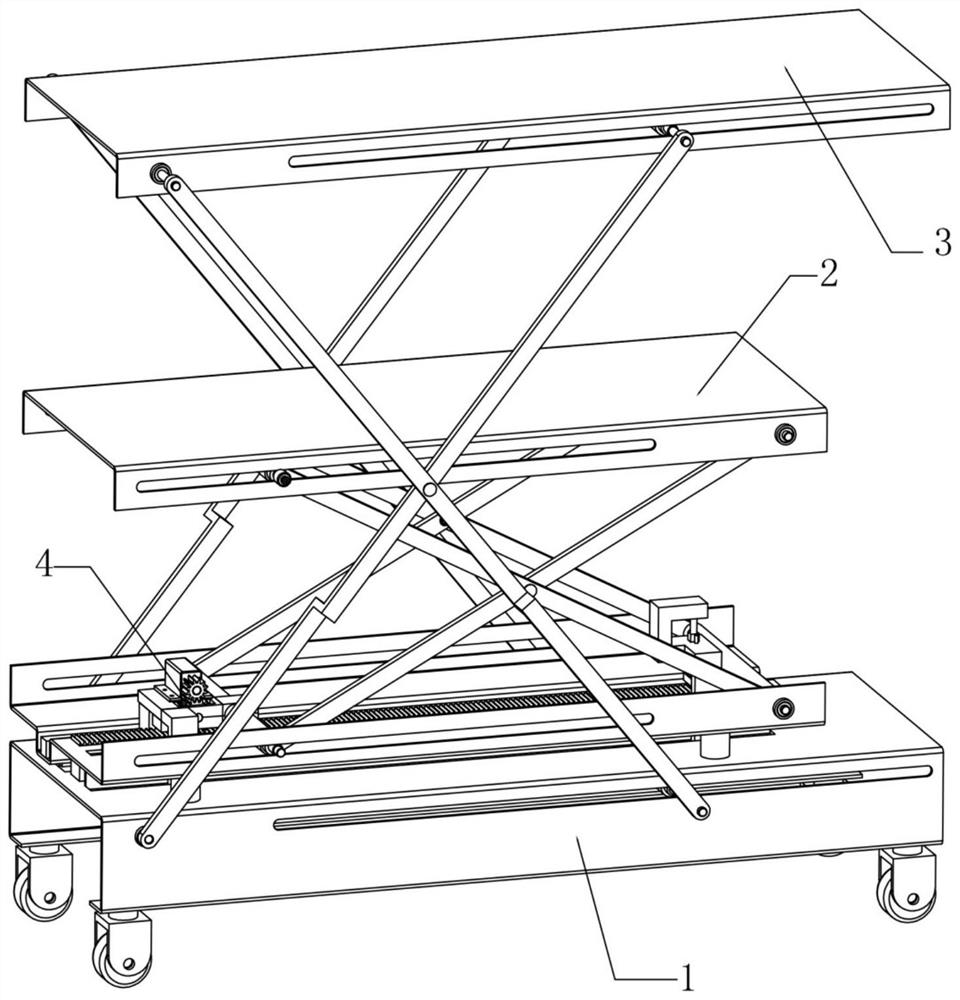

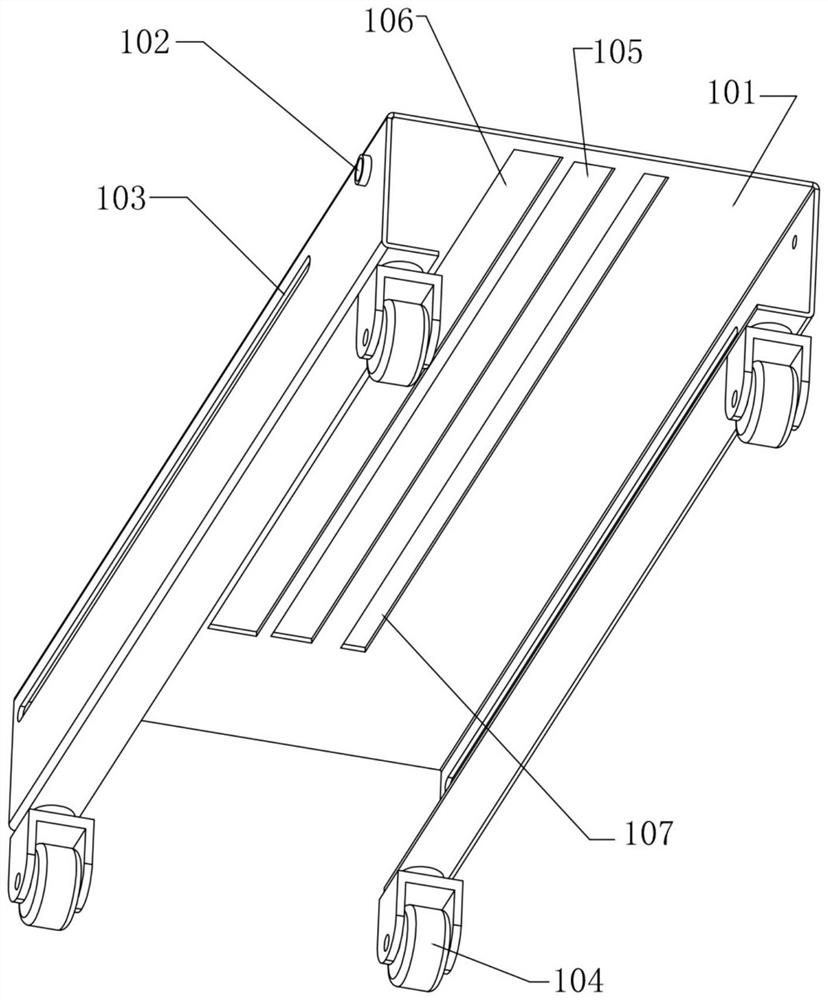

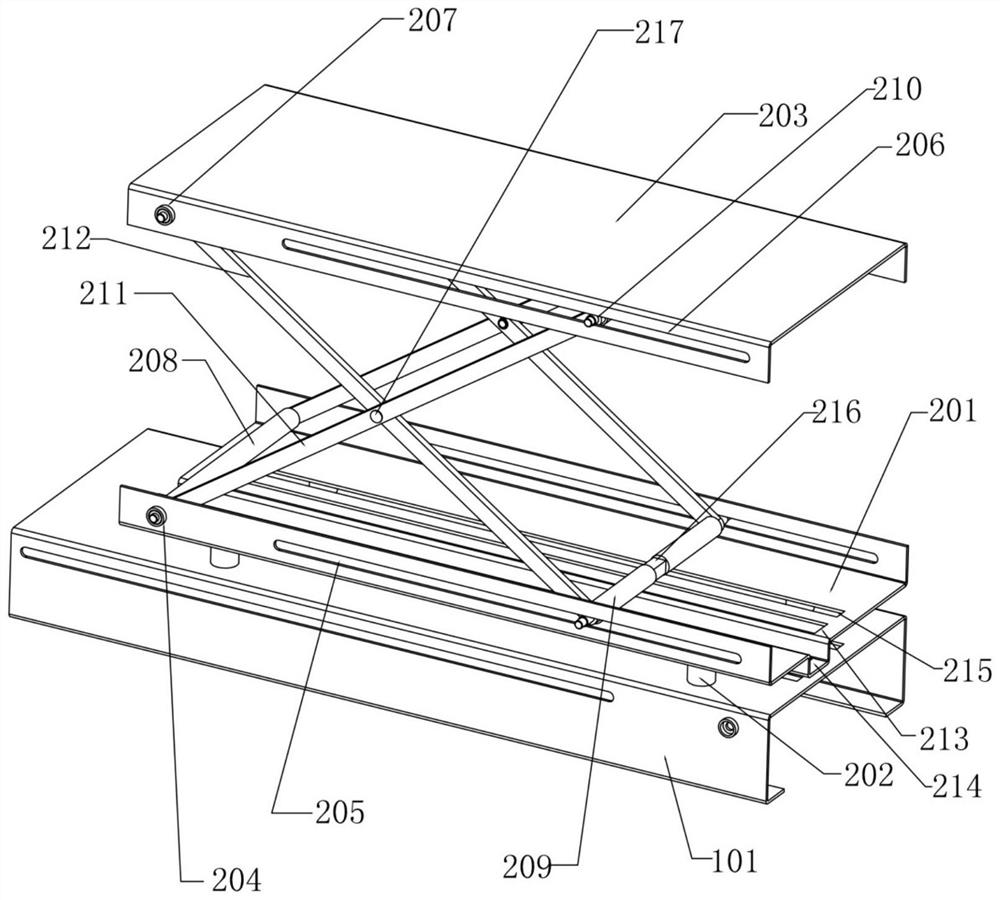

[0042] The present invention realizes the example of multi-position expansion and contraction of different construction platforms such as figure 1 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 9 and Figure 10 As shown, the base 101 in the base assembly 1 is a fixed base, the first-level base 201 in the first-level platform assembly 2 is fixed on the upper plane of the base 101 through an array of first-level support seats 202, and the first-level platform 203 is located on the top of the first-level base 201 Above, two sets of first-stage fixed connecting rods 211 are symmetrically arranged on both sides of one end of the first-stage base 201, and above are symmetrically arranged on both sides of the other end of the first-stage platform 203, above two sets of first-stage moving connecting rods 212. It is symmetrically arranged on both sides of one end of the first-stage platform 203, and symmetrically arranged on both sides of the other end of the first-stage ...

Embodiment 2

[0054] The present invention realizes the locking examples of different heights of different lifting platforms such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 8 and Figure 11 As shown, one side of each driving assembly 405 is provided with a locking assembly 406, the locking seat 40601 in the locking assembly 406 is an inverted U-shaped structure, and the front end of the inverted U-shaped structure is fixed on one side of the driving top seat 40502. The ends of the inverted U-shaped structure of the set of locking connectors 40601 respectively pass through the locking sliding tooth position 107 and the primary base sliding tooth position 215, and then set on the opposite side of a set of tooth surfaces of the linkage rack 401 that provides a matching path for the current drive assembly 405 On the other set of tooth surfaces, locking teeth 40602 are respectively provided on both sides of the upper and lower tooth surfaces of the linkage rack 401,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com