Integrated vitrified freezing/resuscitation instrument

An integrated vitrification technology, applied in biochemical instruments, biochemical cleaning devices, preservation of human or animal bodies, etc., can solve problems such as heavy workload, out-of-control time management, supply chain risks, etc., and achieve high work efficiency , Improve applicability and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

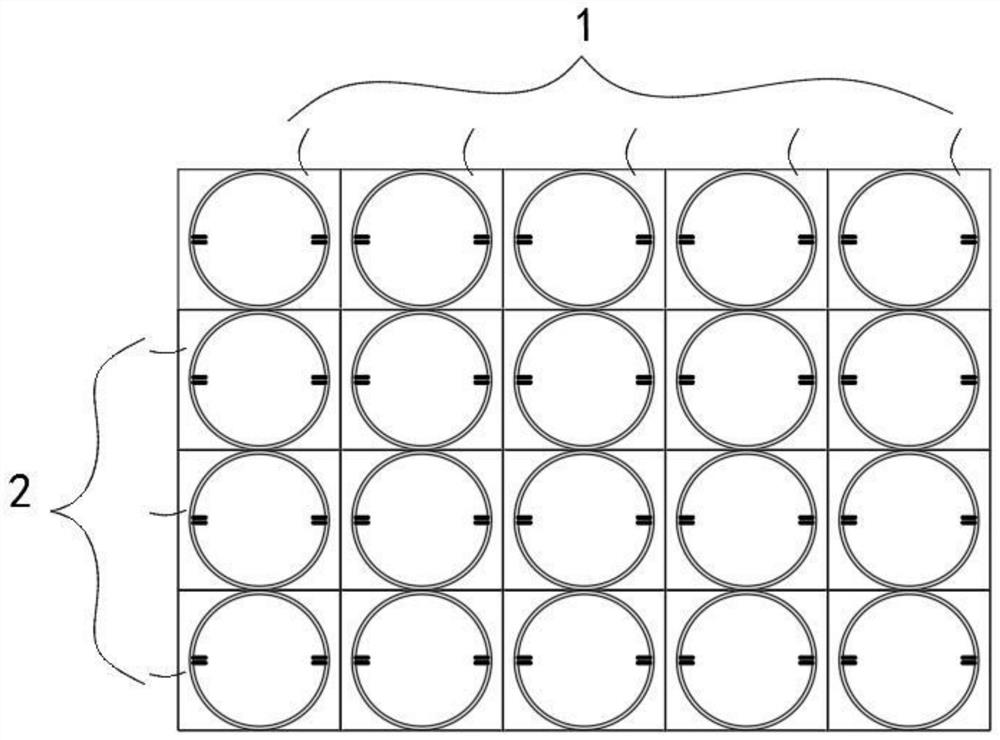

[0058] Integrated vitrification / resuscitator, including workbench, reagent carrying home port system, transmission system, automatic liquid injection system, liquid nitrogen transportation system, zoned temperature control system and computer.

[0059] Wherein, the workbench is provided with several rows of processing systems, and the workbench is also provided with liquid nitrogen storage tanks 1 corresponding to the processing systems. The processing system includes several groups of reagent tanks 2 arranged at intervals. Two heating zones are respectively arranged in the reagent tank 2, and the reagent tank 2 is also provided with a reagent carrier 4.

[0060] Wherein the zoned temperature control system also includes a temperature acquisition unit, a heating plate and a temperature control device, the temperature acquisition unit is respectively connected with the heating plate and the temperature control device; the heating plate is connected with the temperature control d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com