Multi-axis blade grinding production clamp

A fixture and blade technology, which is applied in the field of multi-axis blade grinding production fixtures, can solve the problems that the surface quality of the blade is not as good as the processing part without interpolation and linkage, the precision and efficiency of the processing type are reduced, and the blade with complex forming is not suitable for use. Effects of good mechanics and kinematic models, reduced production costs, easy equipment standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

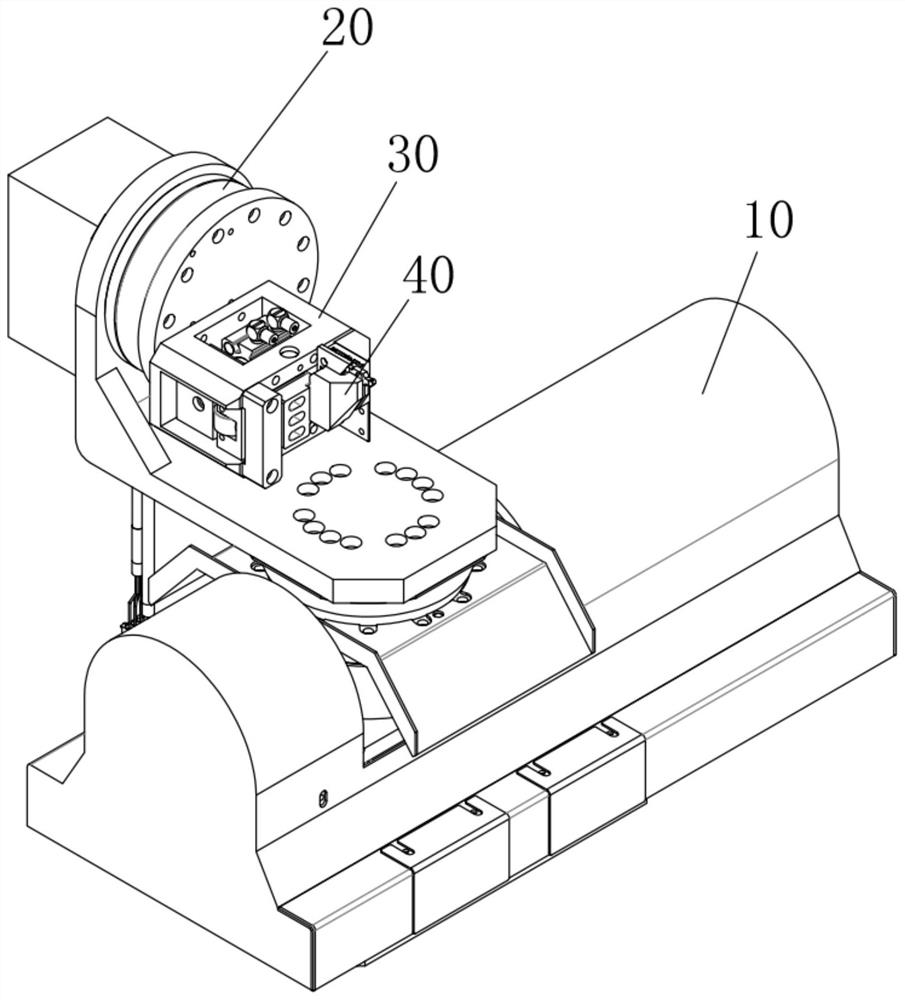

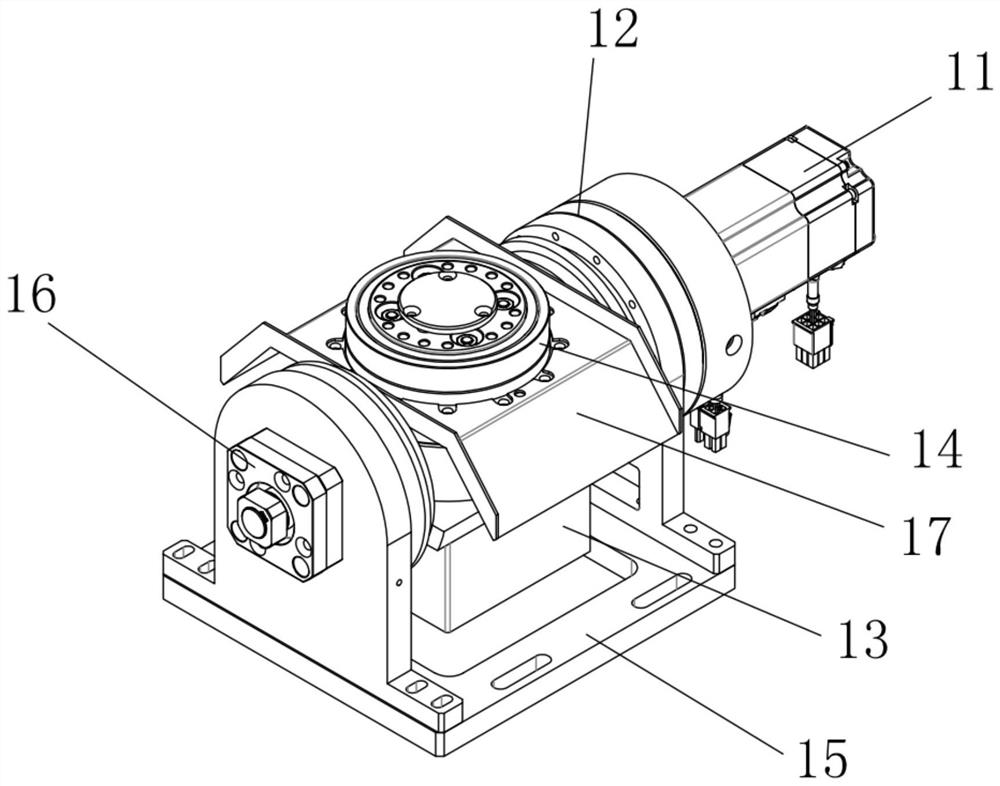

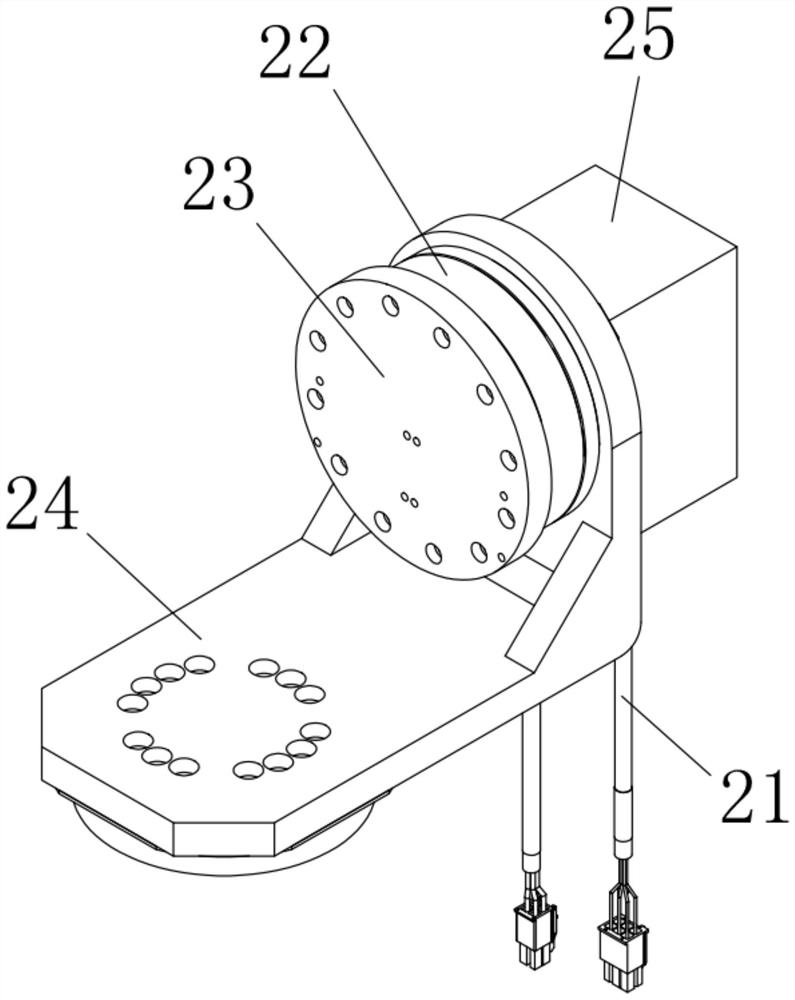

[0033] see Figure 1 to Figure 1 0. In this embodiment, the present invention provides a multi-axis blade grinding production jig, including: a rotating base 10 , an A-axis rotating assembly 20 , a jig body 30 , and a positioning clamping assembly 40 .

[0034] The rotating base 10 can be used to drive the clamp body 30 to move. The A-axis rotating assembly 20 is arranged on the rotating base 10 and can move under the drive of the rotating base 10. The A-axis rotating assembly 20 is used to realize the rotation of the fixture body 30 around the A-axis. The A-axis rotation assembly 20 can realize 360° rotation, and the A-axis rotation assembly 20 includes a fixture mounting plate 23 . The clamp body 30 is arranged on the clamp mounting plate 23 and can move under the drive of the A-axis rotation assembly 20, the clamp body 30 is used to inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com