Manufacturing and processing technology for lost foam casting wax mold

A technology of lost foam casting and processing technology, which is applied in casting and molding equipment and other directions, can solve the problem of the connection between the branches of the lost wax mold and the main body of the lost wax mold, reduce the efficiency of welding between the main body and the branches of the lost wax mold, and reduce the disappearance of the wax mold. Problems such as the effect of welding between the main body of the wax mold and the branches to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

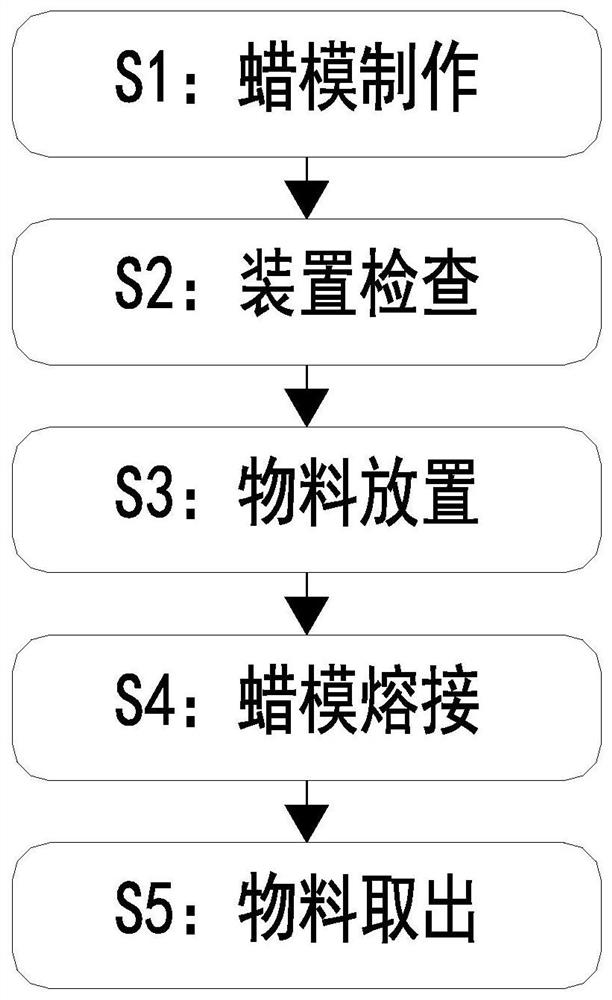

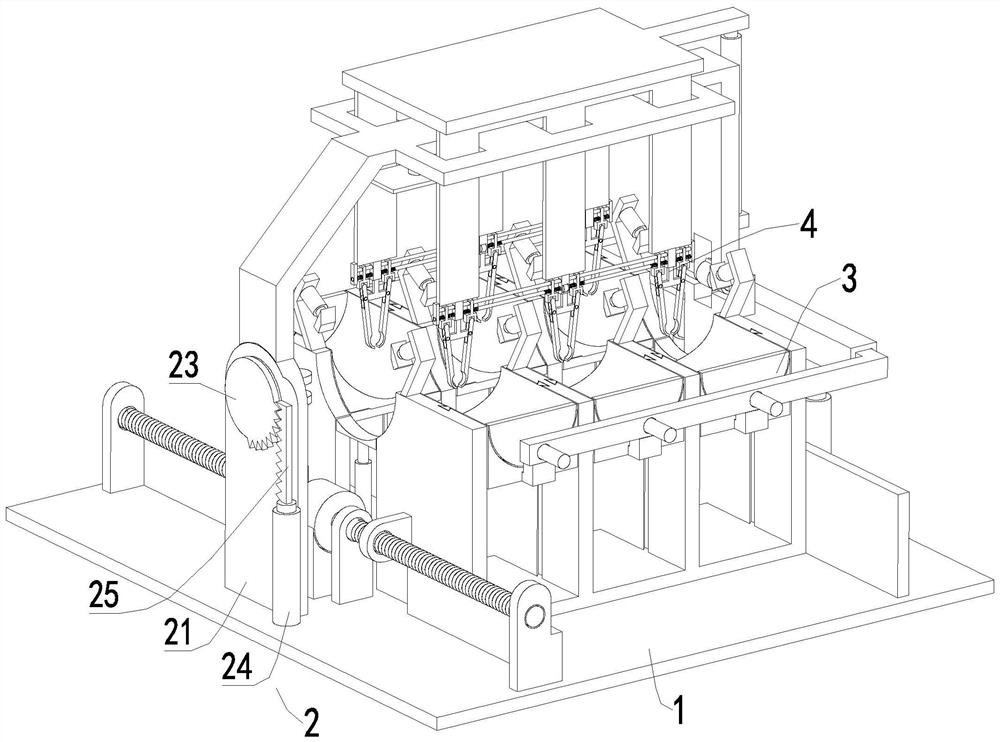

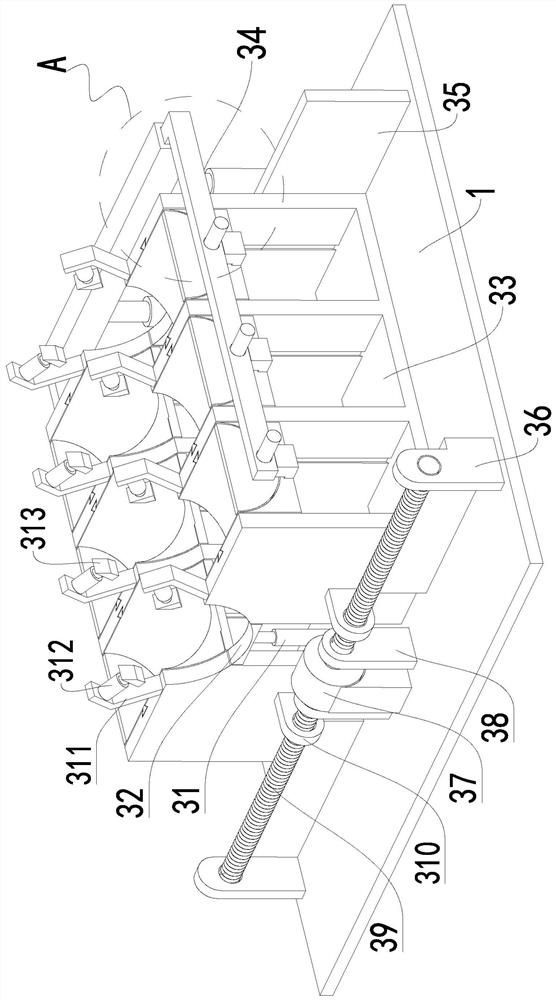

[0038] Such as Figure 1 to Figure 9 As shown, a lost foam casting wax pattern manufacturing process, the lost foam casting wax pattern manufacturing process adopts the following lost foam casting wax pattern manufacturing processing device, the lost foam casting wax pattern manufacturing processing device includes a base 1, a driving mechanism 2 , the supporting mechanism 3 and the welding mechanism 4, the driving mechanism 2 and the supporting mechanism 3 are arranged on the upper end surface of the base 1 from left to right, and the upper end of the driving mechanism 2 and the rear side of the upper end of the base 1 are located above the supporting mechanism 3 A welding mechanism 4 is provided;

[0039] During specific work, at first the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com