Automatic buckling device for refrigerator liner production

A freezer liner and automatic buckle technology, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of low efficiency, large occupation of personnel, mechanical injury of special punching machines and bending machines, etc., to improve efficiency , Improve the accuracy, and stabilize the fastening pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

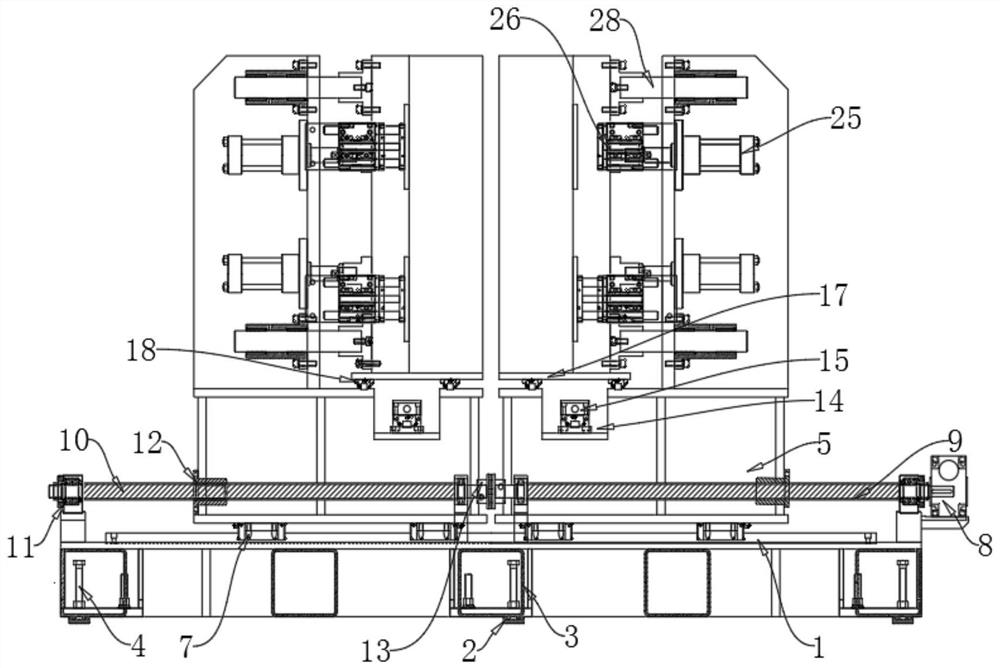

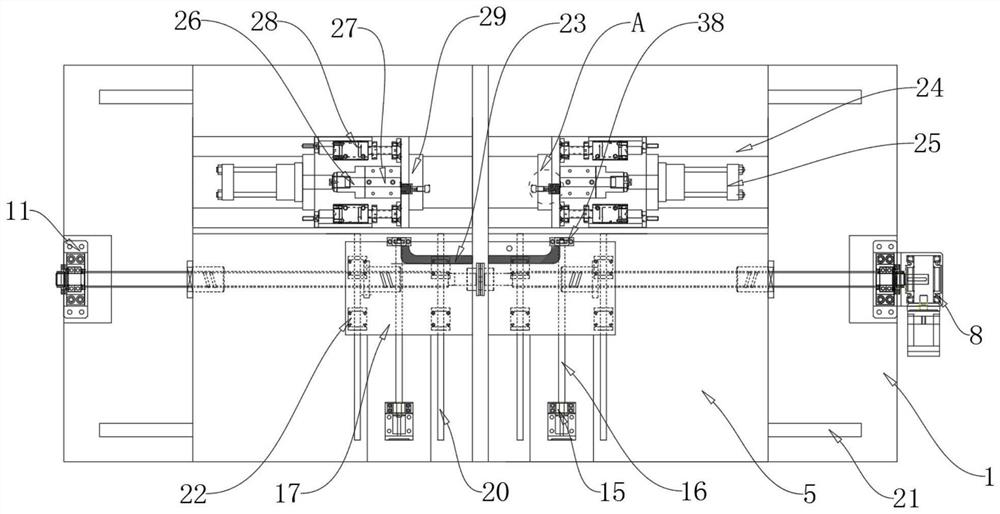

[0033] An automatic fastening device for the production of refrigerator liners, comprising a base 1, a first moving plate 5 is slidably connected to both sides of the top of the base 1, and a second moving plate is slidably connected to the tops of the two first moving plates 5 17. The tops of the two second moving plates 17 are fixedly connected with expansion boards 23 for binding the inner container of the refrigerator, and the top of the base 1 is fixedly connected with two U-shaped plates 24, and the sides of the two U-shaped plates 24 are close to each other. Both are provided with an extruding mechanism for fastening the inner container of the refrigerator, and the middle part of the top of the base 1 is fixedly connected with an inner formwork 29, and the two inner formworks 29 are located at the middle position between the two U-shaped plates 24. The interior of the inner formwork 29 is provided with a positioning mechanism for initially fixing the refrigerator inner c...

Embodiment 2

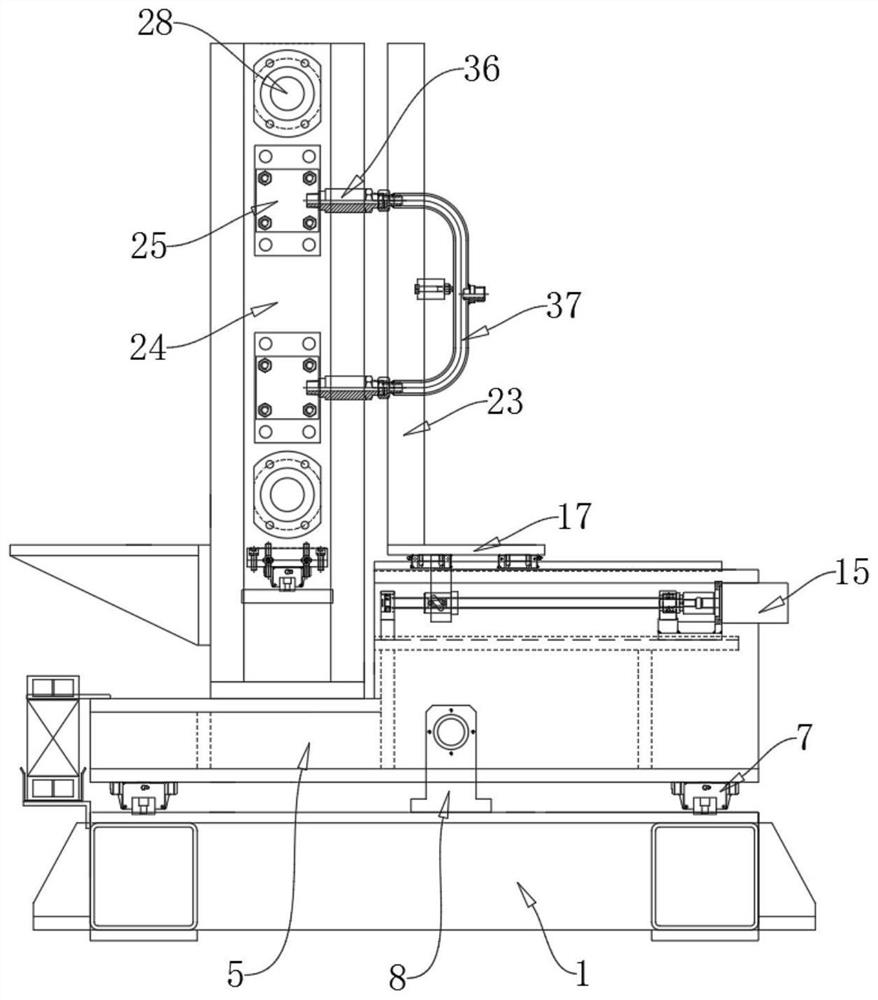

[0043] An automatic fastening device for the production of a freezer liner. On the basis of Embodiment 1, the extrusion mechanism includes two sets of oil cylinders 25, and the two sets of oil cylinders 25 are installed inside the corresponding U-shaped plate 24. The two sets of oil cylinders 25 The sides close to each other are equipped with cylinders 26, and the sides of the two sets of cylinders 26 close to each other are fixedly connected with buckling mold strips 27 that squeeze the inner liner of the refrigerator, and one side of the buckle mold strips 27 is provided with a notch 35.

[0044] In this embodiment, there are two sets of oil cylinders 25 in each of the two sets of oil cylinders 25 , and oil cylinder joints 36 are installed on one side of each set of oil cylinders 25 , and oil pipes 37 are communicated between each set of oil cylinder joints 36 .

[0045] Specifically, the oil cylinder joints 36 are connected through oil pipes 37, which is convenient for refu...

Embodiment 3

[0049] An automatic fastening device for the production of a freezer liner. On the basis of Embodiment 1, the positioning mechanism includes a T-shaped plate 33, and the inside of the inner template 29 is provided with a chute 30 and a T-shaped groove 32. The chute 30 and The T-shaped grooves 32 communicate with each other, the inner thread of the chute 30 is connected with a nut 31 , the inner sliding connection of the T-shaped groove 32 is connected with a T-shaped plate 33 , and a spring 34 is fixedly connected between the nut 31 and the T-shaped plate 33 .

[0050] Specifically, when the fastening positions of the large and small templates are located inside the notch 35, the T-shaped plate 33 fixes one side of the templates, preventing the large and small templates from sliding when they are engaged.

[0051] Working principle: Start the first driving device 8, drive the first screw 9 and the second screw 10 to rotate, thereby driving the first moving plate 5 to move, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com