Upper cover structure of post articulated printer with paper tearing function

A printer, hinged technology, applied in the direction of printing device, printing, etc., can solve the problem of tearing difficulty, etc., to achieve the effect of tearing paper more effectively and neatly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

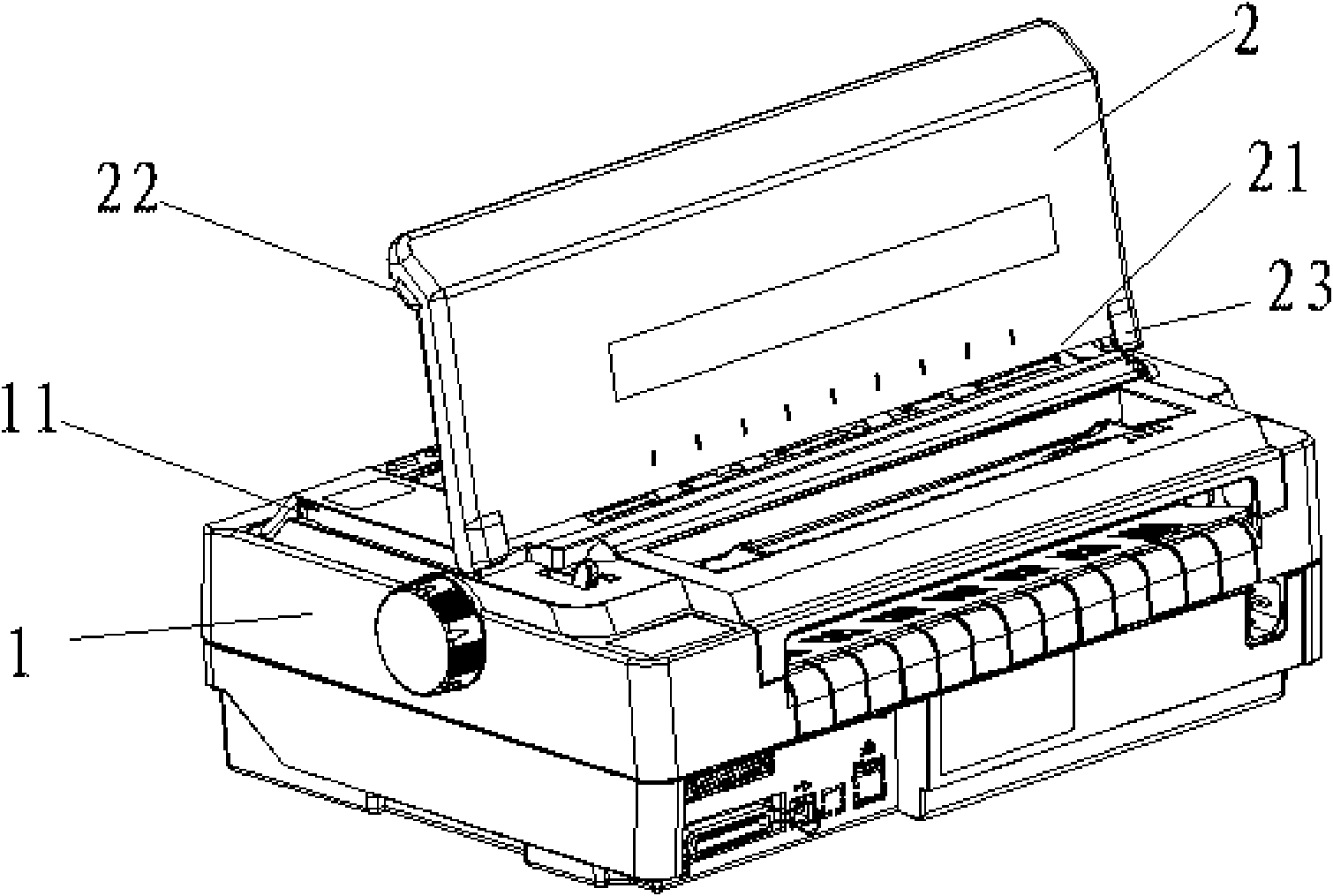

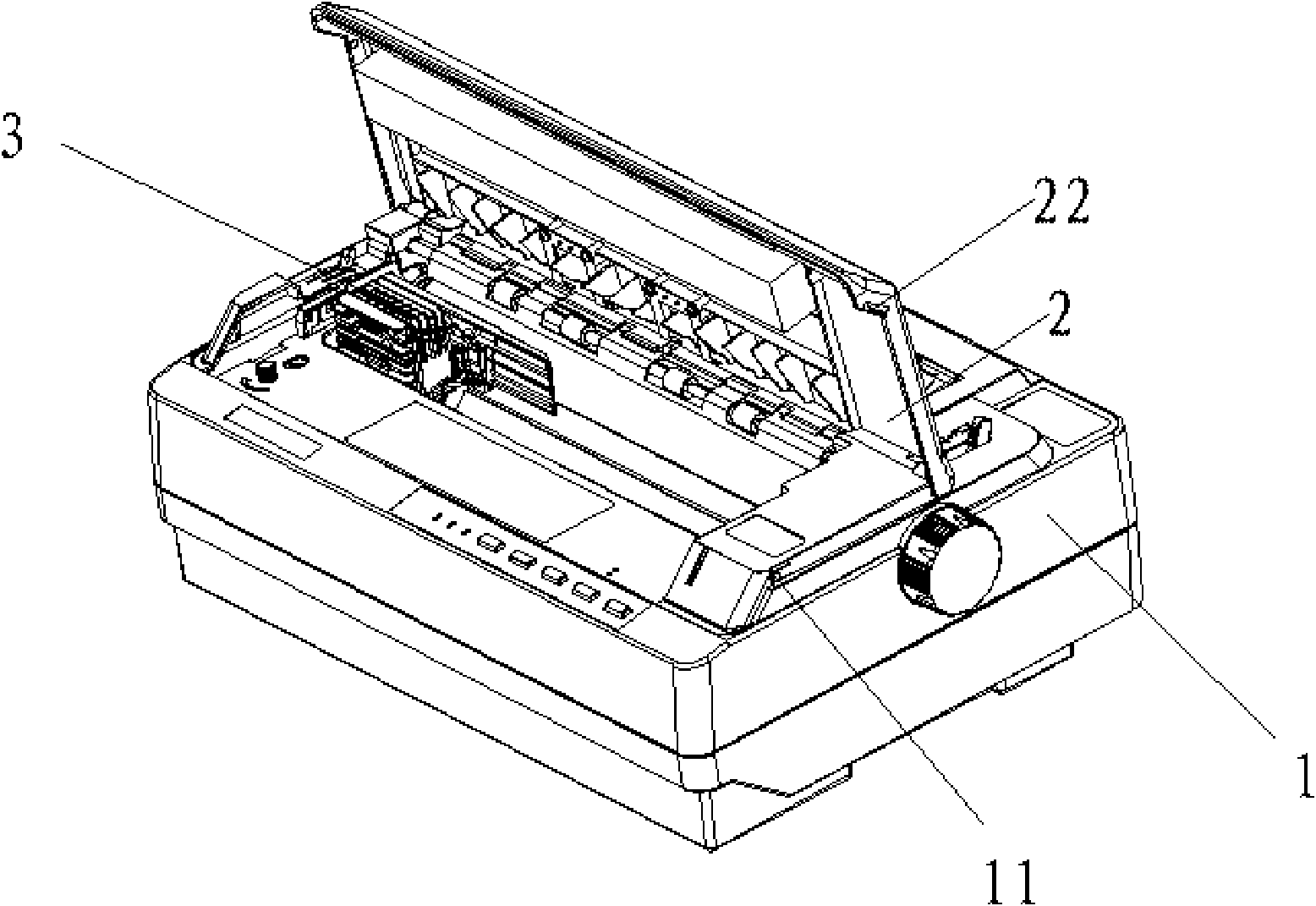

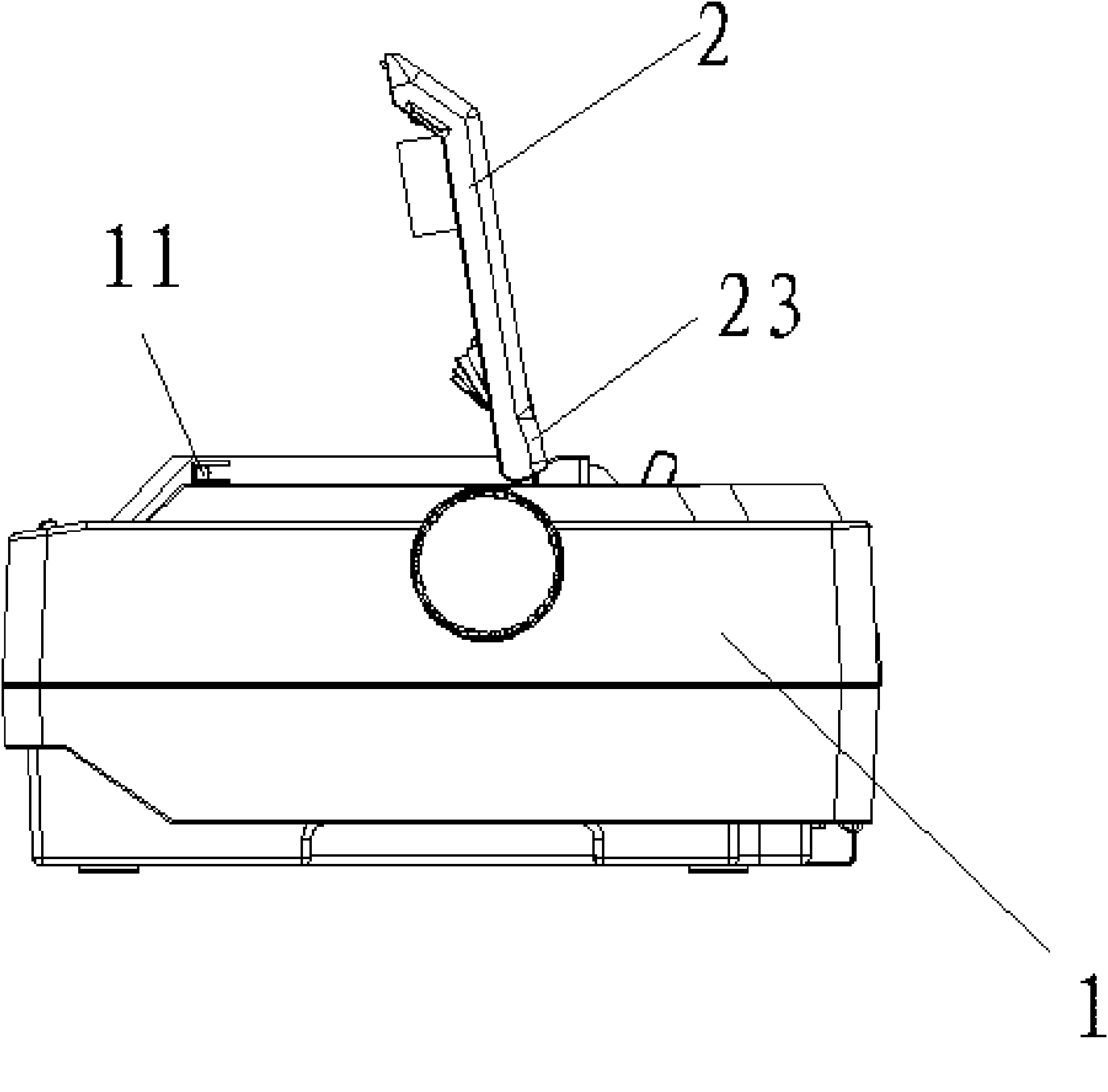

[0013] refer to figure 1 , 2 , 3, a rear hinged printer cover structure with paper tearing function, which includes a printer cover 2 hinged in the middle of the printer casing 1, the printer cover 2 is sealed and covered on the printing device 3, the printer A tearing edge 21 is provided on the side of the paper outlet of the upper cover 2 , and the described tearing edge 21 is a beveled edge arranged on the side of the paper outlet of the printer upper cover 2 . Of course, according to actual needs, the paper tearing blade 21 can also adopt other structural forms.

[0014] In order to ensure that the tearing paper is more effective and tidy, the printer casing 1 is provided with a push-type boss structure 11 that is clamped on the inner side of the front end of the printer upper cover 2. This design enables the printer upper cover 2 to be firmly fastened on the on the printer case 1. In addition, the two sides of the front end of the printer top cover 2 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com