Machine head structure of jewelry processing machine

A jewelry processing and machine head technology, applied in clothing, application, jewelry and other directions, can solve the problems of gold and silver jewelry processing errors, fixed or just moving up and down, large metal loss, etc., to achieve multi-processing angles, multi-directional adjustment , the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

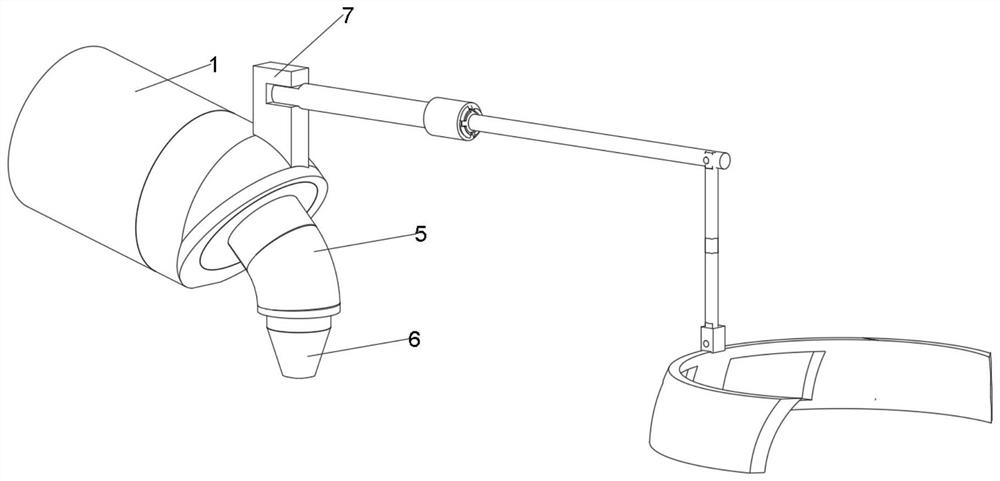

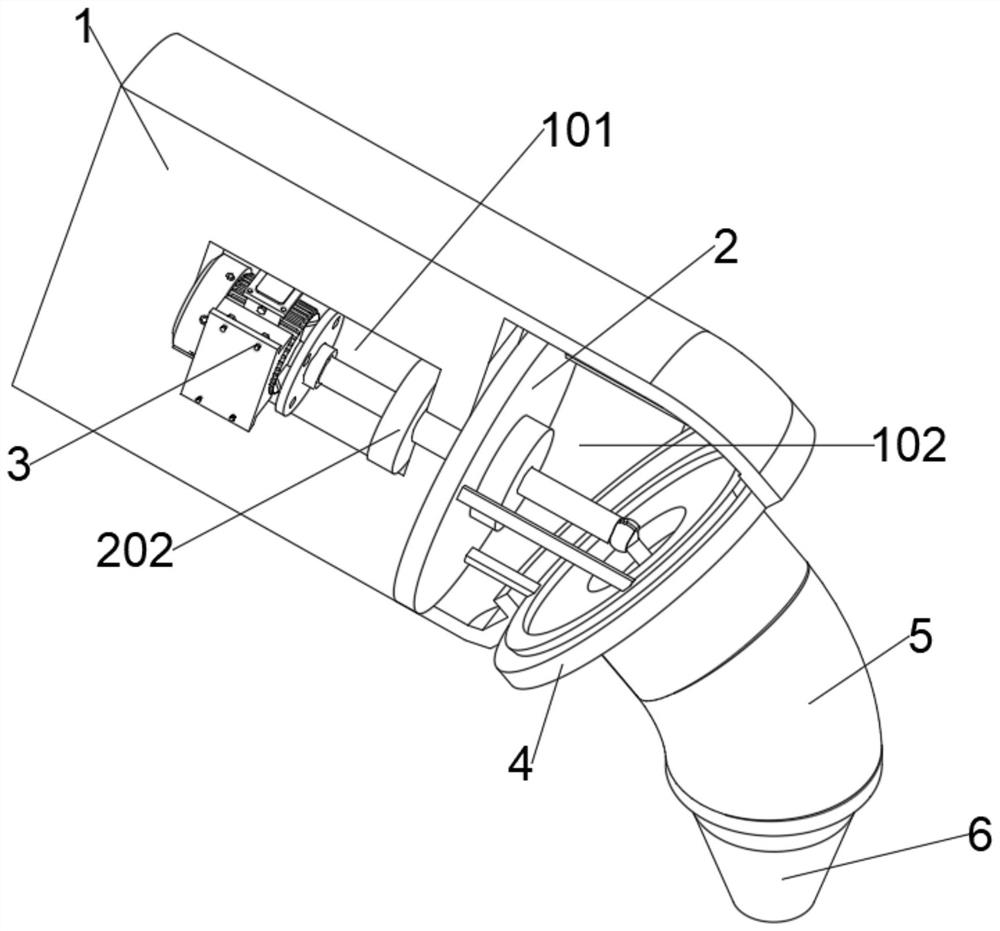

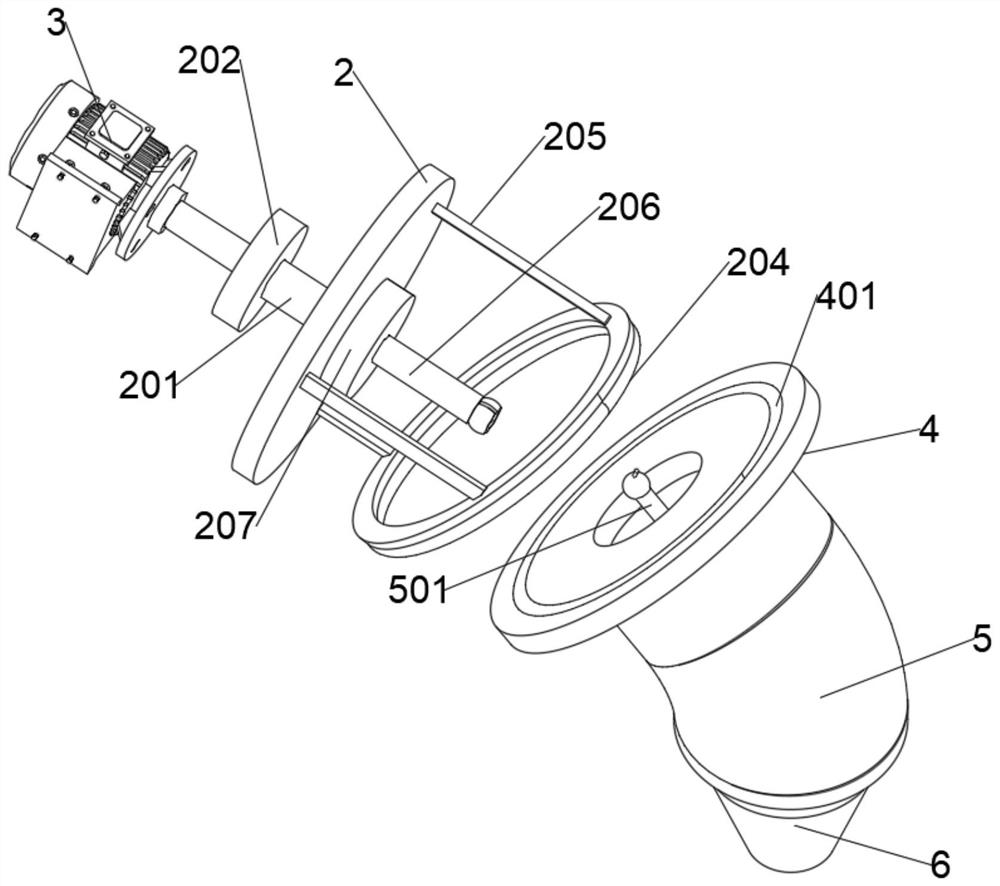

[0028] see Figure 1-8 , the present invention provides a kind of technical scheme:

[0029]A head structure of a jewelry processing machine, comprising a columnar block 1, an organic cavity 101 is provided on the rear side of the columnar block 1, a cavity 102 is provided on the front side of the columnar block 1, a turntable 2 is arranged inside the cavity 102, and a turntable 2 There is a sleeve A201 in the middle of the rear side, the rear end of the sleeve A201 extends through the inner wall of the cavity 102 to the inside of the machine cavity 101 and is sleeved with the limit box A202, the front side of the turntable 2 is provided with a circular track 204, and the rear side of the circular track 204 A plurality of support rods 205 are fixed at equal intervals in a ring shape, a sleeve B206 is provided in the middle of the front side of the turntable 2, the rear end of the sleeve B206 is sleeved with a limit box B207, and the front end of the sleeve B206 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com