Apparatus and method for burning organic material

A technology of organic materials and combustion space, applied in the direction of combustion method, combustion type, air heater, etc., can solve the problems of high cost, low efficiency, slow combustion, etc., and achieve the effect of reducing consumption and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below based on a preferred embodiment. The invention is not limited to the described embodiments. The present invention is intended to cover all alternatives, modifications and equivalents included within the principles and scope of the present invention.

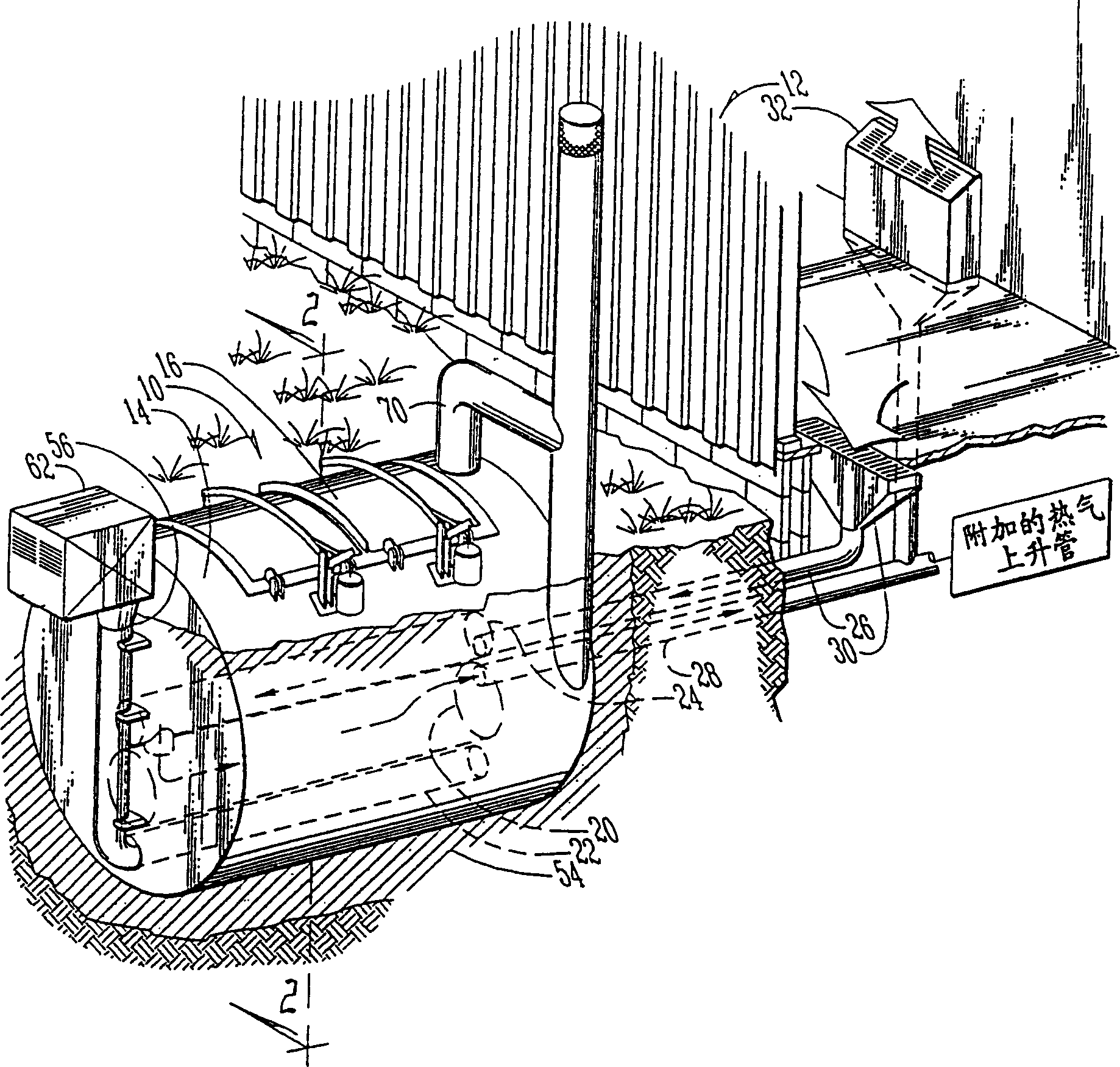

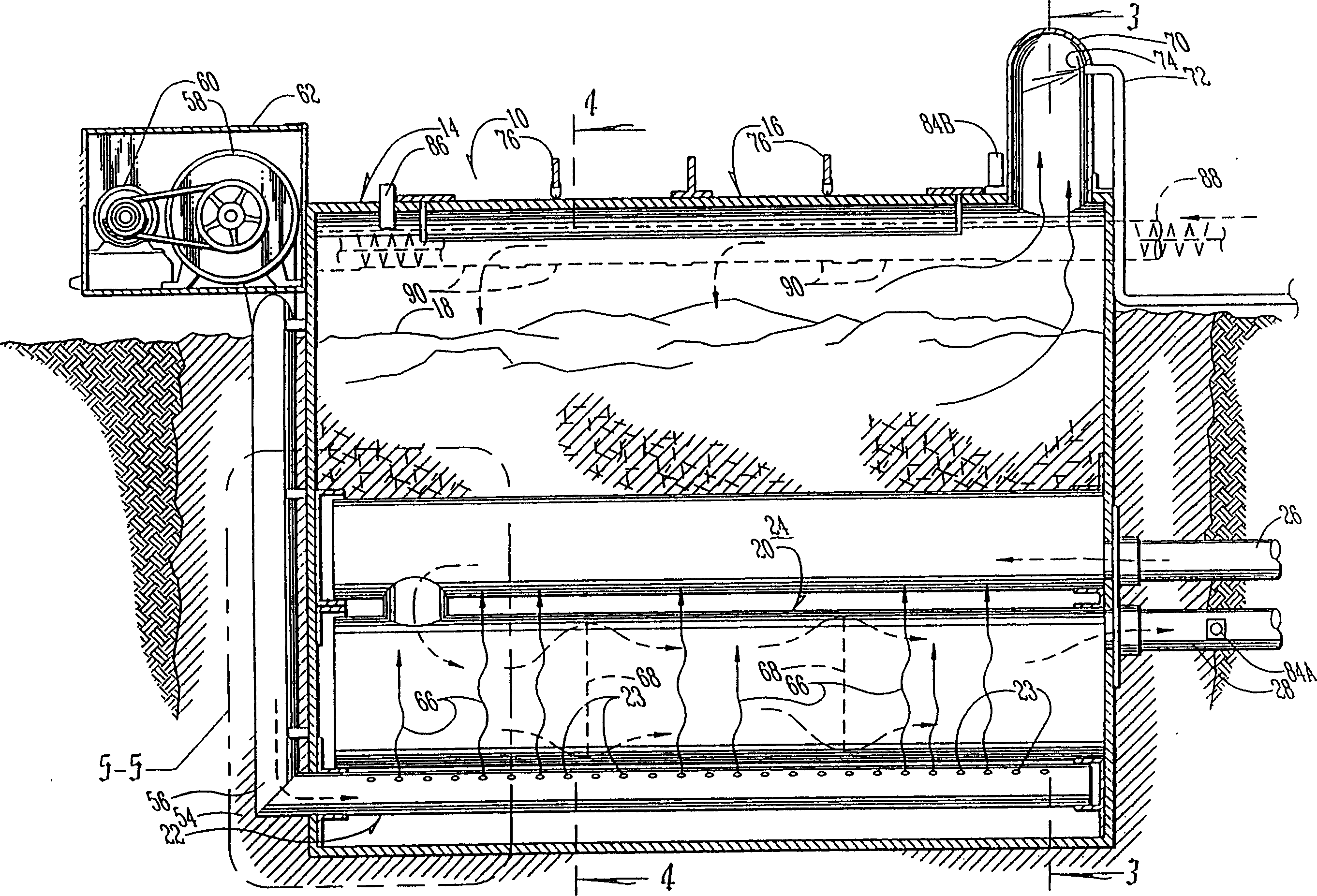

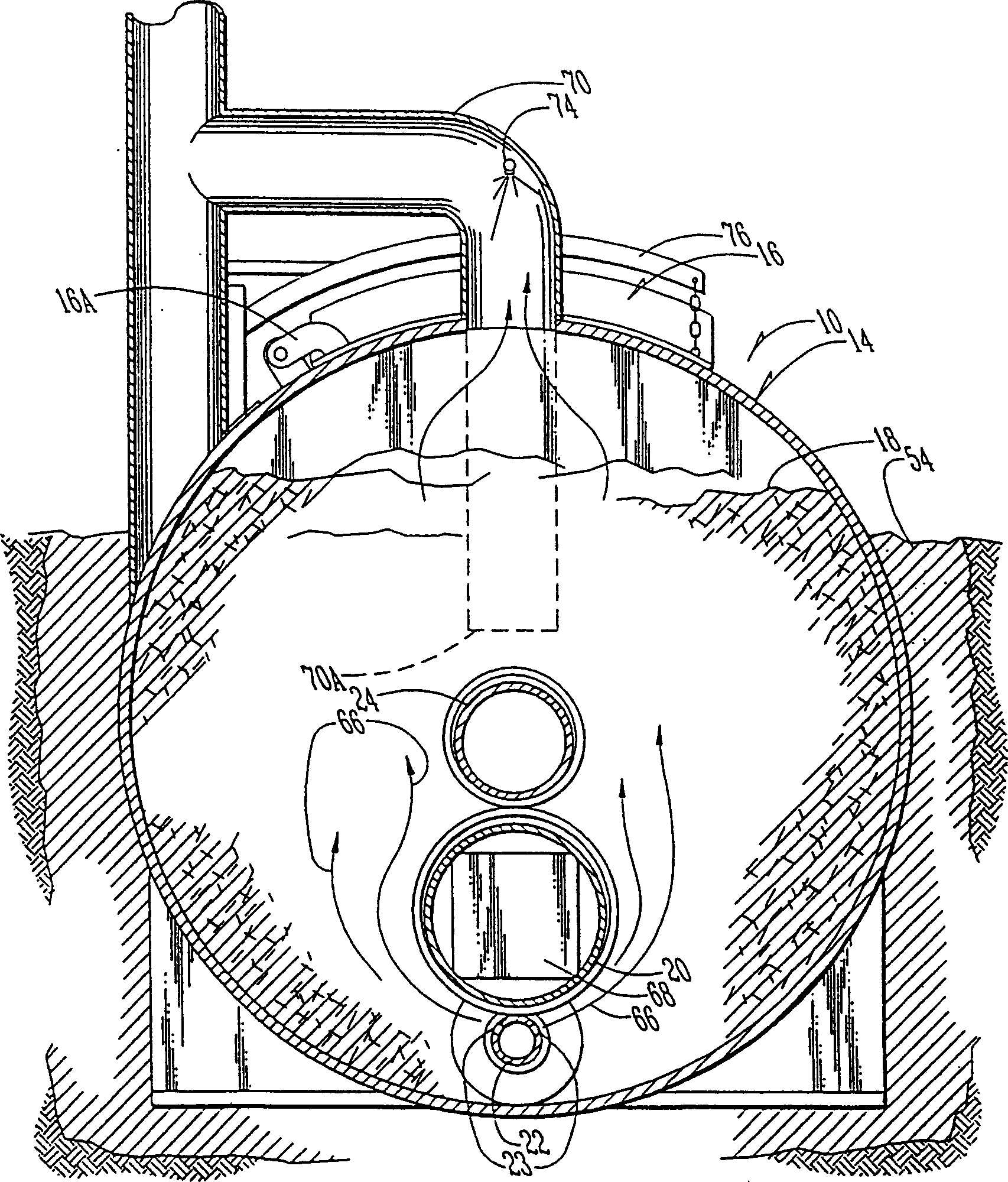

[0028] figure 1 Device for burning organic feedlot bedding waste according to the invention is shown. figure 1 Included is a furnace 10 partially buried in the earth, adjacent to a house 12 . Figure 2 to Figure 5 Furnace 10 is shown in more detail. The furnace 10 includes a cylindrical fire box 14 having two ends. Firebox 14 is preferably made of thick iron. Door 16 is provided on top of firebox 14 and is opened and closed by hinge pin 16A. A heat exchanger 20 is located within the firebox. Installing the heat exchanger 20 within the firebox 14 has its advantages. With the door 16 open, a quantity of fuel 18 is deposited into the firebox 14, around the heat exchanger 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com