A beam-column energy-dissipating connector based on a U-shaped plate and its construction method

A connecting piece and beam-column technology, which is applied to the beam-column energy-dissipating connecting piece based on U-shaped plate and its construction field, can solve the problems of self-reset ability and weak energy-dissipating ability, avoid the decrease of bending resistance and reduce residual Deformation, to achieve the effect of energy dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to solve the technical problems of the present invention, the technical solution and beneficial effects are more clearly understood, the following specific embodiments, the present invention will be further elaborated in detail. It should be understood that the specific embodiments described herein are merely used to explain the present invention and are not intended to qualify the present invention.

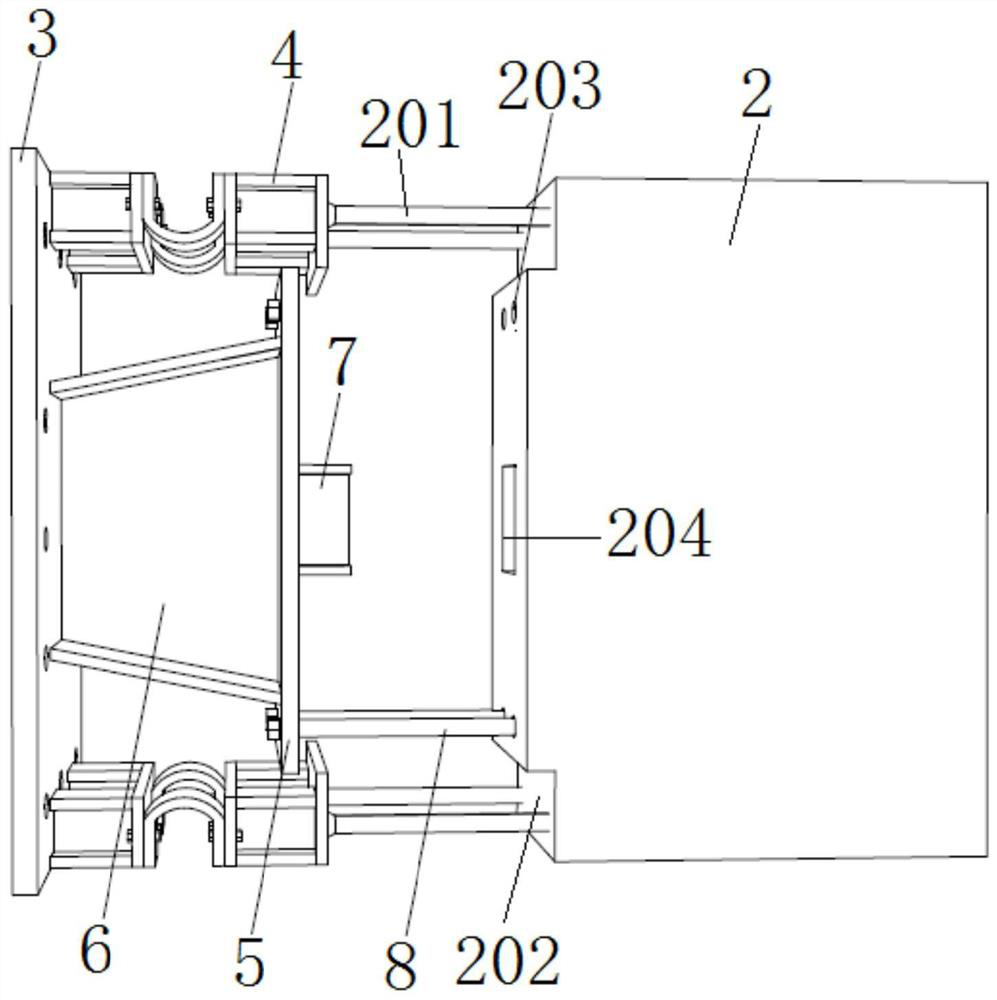

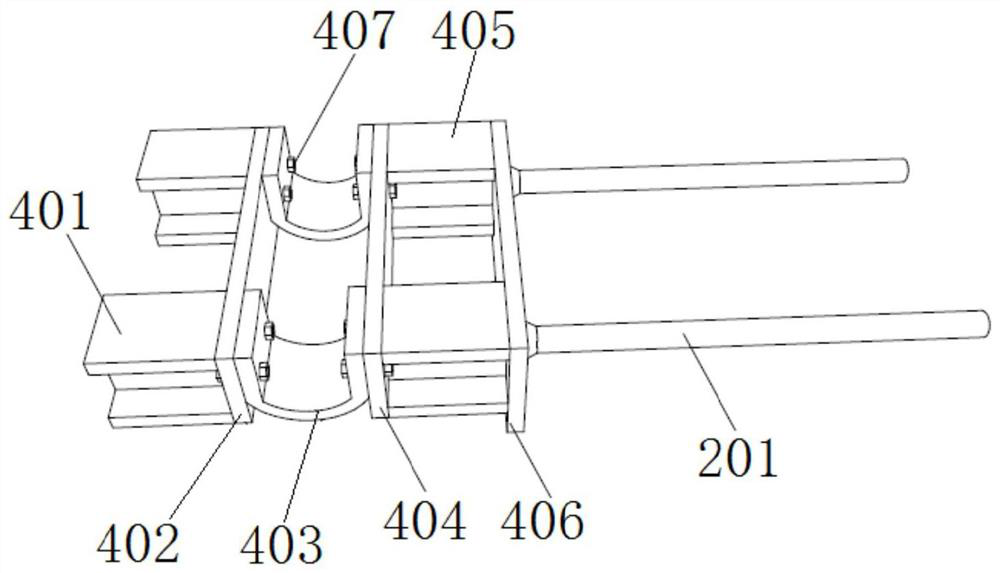

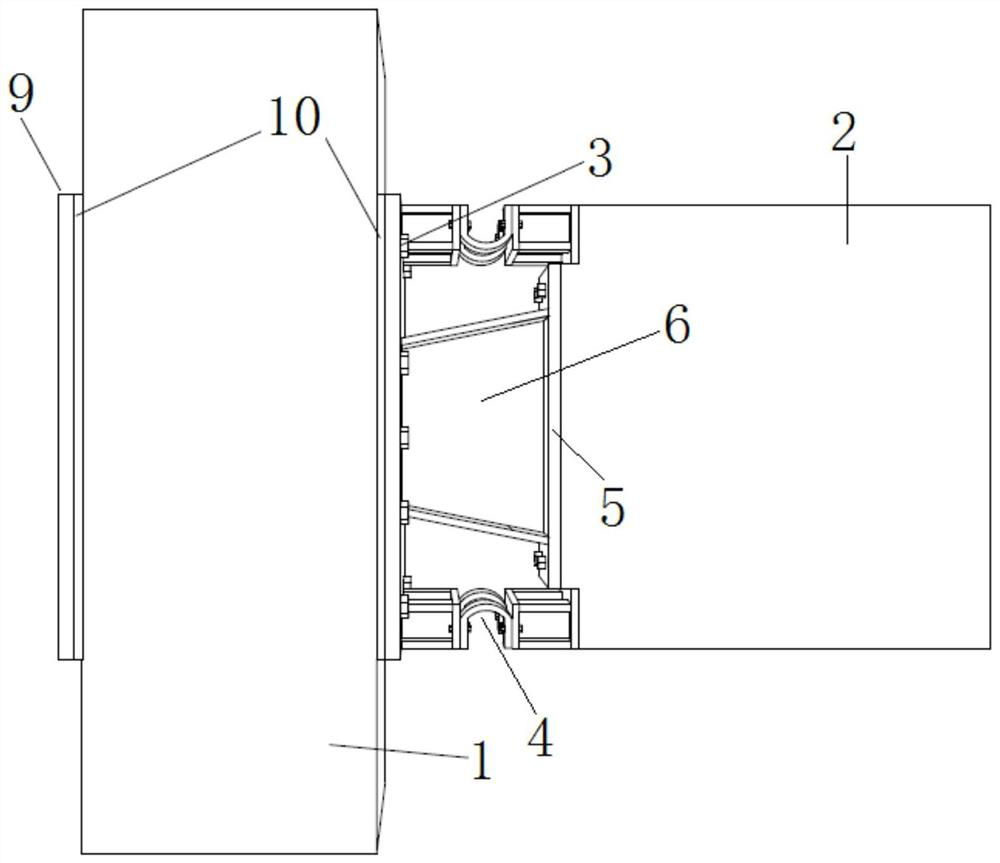

[0038] If attached Figure 1-3 As shown, the present invention provides a U-shaped plate-based beam and column energy-consuming connector, the beam-column energy-consuming connector is provided at the connection node of the prefabricated column 1 and the prefabricated beam 2; The beam and column energy-consuming connectors include column side end plates 3, two energy-consuming units 4, beam side end plates 5, connecting steel 6, shear 7, prestressed ribs 8 and column side reinforcement plates 9.

[0039] Column side end plate 3 and beam side end plate 5 vertical parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com