Polyvinyl chloride plastic regeneration cleaning sewage treatment equipment and treatment method thereof

A technology for cleaning sewage and polyvinyl chloride. It is used in neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Too much or too little, etc., to achieve the effect of improving the mixing effect and reducing the moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

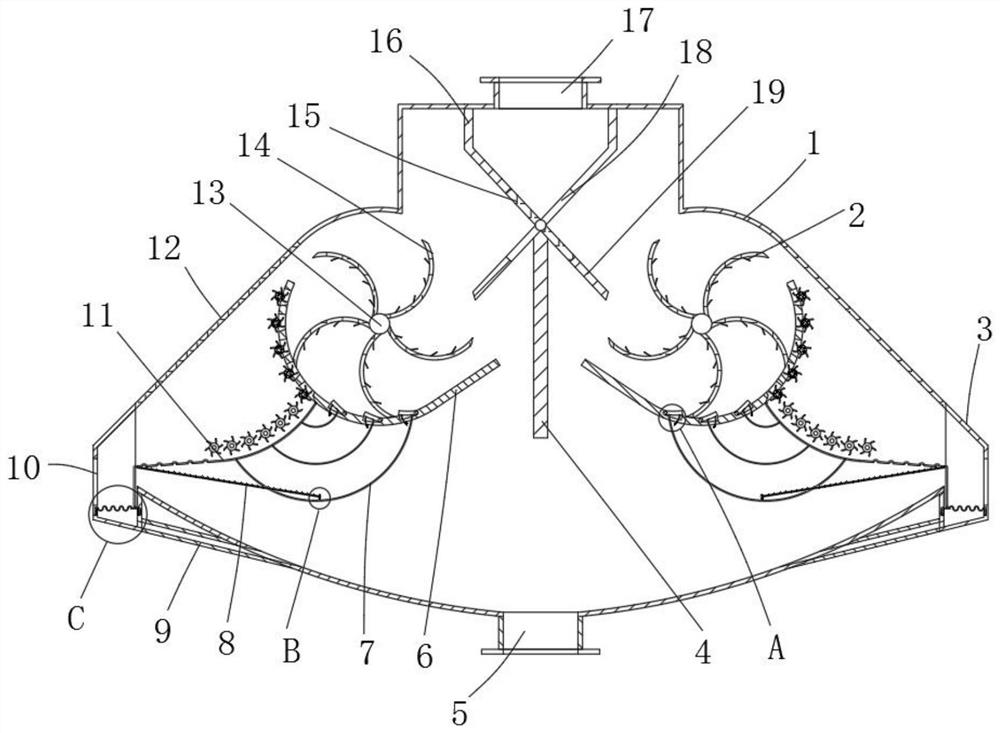

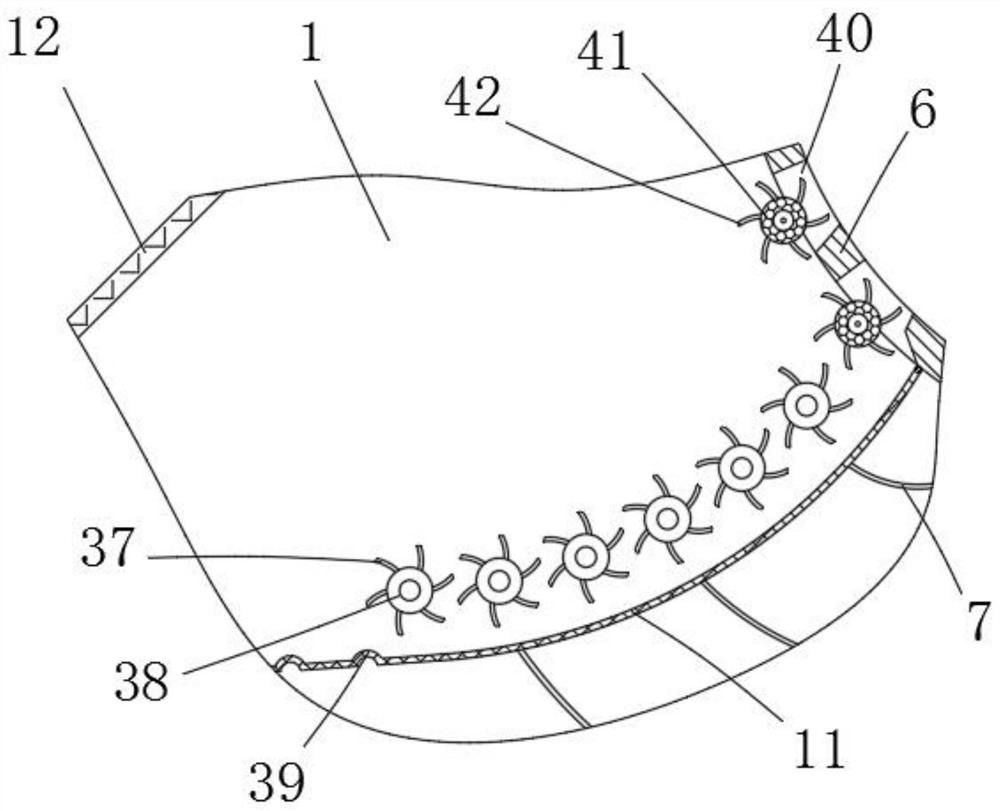

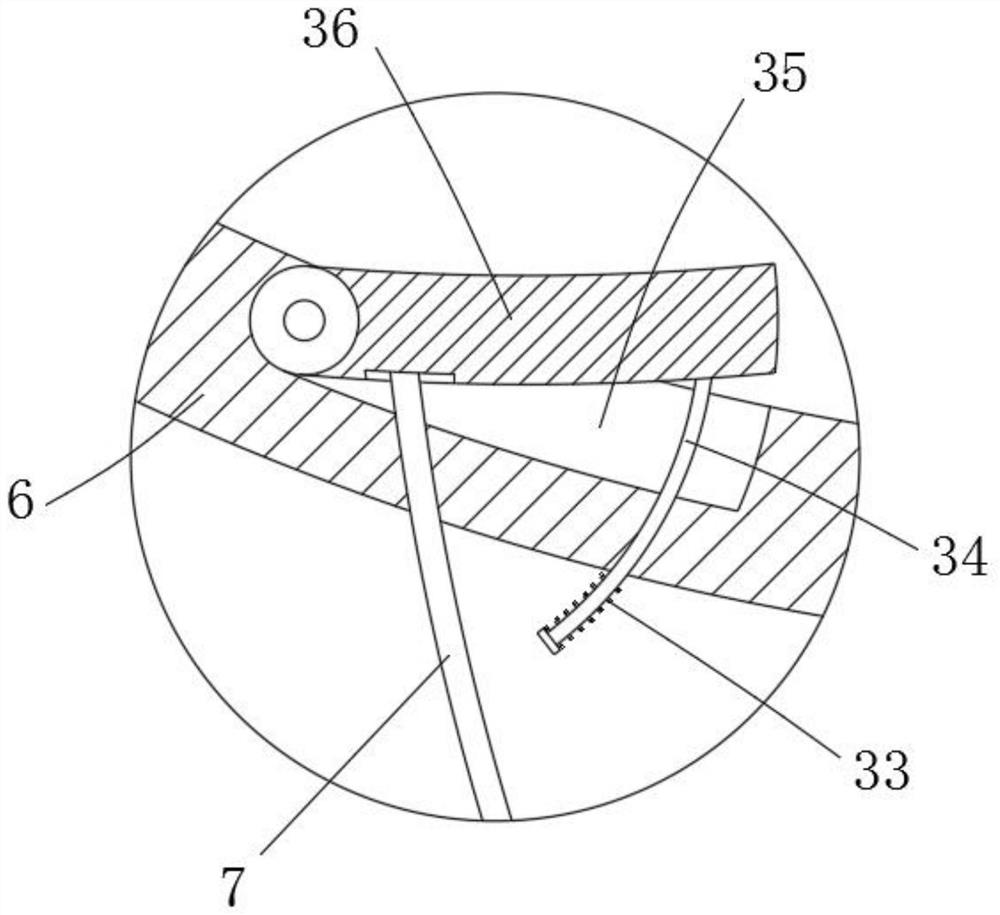

[0037]A polyvinyl chloride plastic recycled cleaning sewage treatment equipment, comprising an outer box 1, the top outer wall of the outer box 1 is provided with a water inlet 17, the bottom outer wall of the outer box 1 is provided with a water outlet 5, the outer box 1 is located at the inlet The side inner wall below the nozzle 17 is provided with a flow diversion mechanism, and both sides below the flow diversion mechanism are respectively provided with a first liquid addition mechanism and a second liquid addition mechanism, the first liquid addition mechanism and the second liquid addition mechanism are symmetrical to each other, and the outer box The side outer wall of the body 1 located on the side of the first liquid addition mechanism and the second liquid addition mechanism is provided with a side door 12. The first liquid addition mechanism includes a rotating shaft 13 that is rotatably connected to the side inner wall of the outer box body 1, and the side outer wal...

Embodiment 2

[0048] A method for treating polyvinyl chloride plastic recycled cleaning sewage, using the polyvinyl chloride plastic recycled cleaning sewage treatment equipment as described in Example 1, the specific steps are as follows:

[0049] S1: Add the chemical solution required for sewage treatment to the liquid storage mechanism, and make the chemical solution not pass through one side of the drum 41;

[0050] S2: Turn the diverter plate 15 through the reversing handle, so that the diverter plate 15 closes one of the water inlets 18, and the sewage enters the water inlet shell 16 from the water inlet 17 and falls along the opened water inlet 18;

[0051] S3: The sewage falls on the concave surface of the corresponding water pocket plate 14 and drives the water pocket plate 14 to rotate, then the sewage falls on the arc plate 6, and the water pocket plate 14 rotates to press the sewage on the arc plate 6 into the water guide groove 40;

[0052] S4: the rotation of the water pocket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com