Elevator

A hoist and base technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problem that the hoist cannot automatically sort the feeding efficiency, etc., and achieve the effect of improving the feeding efficiency and convenient removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

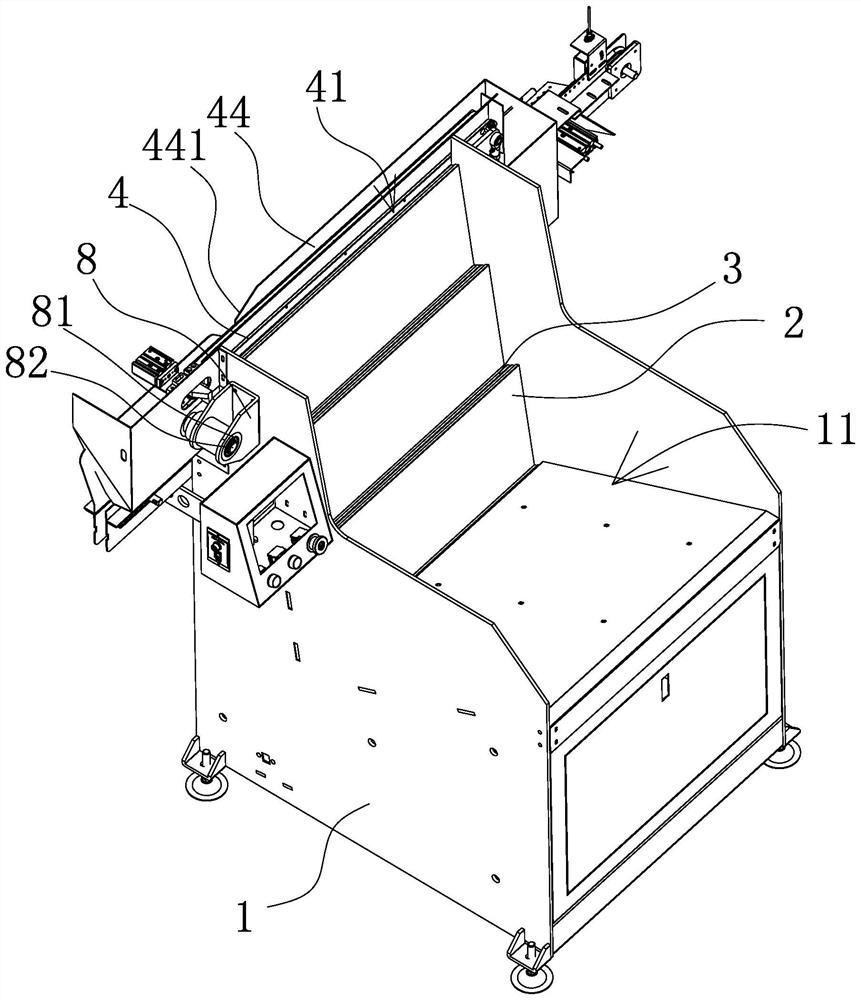

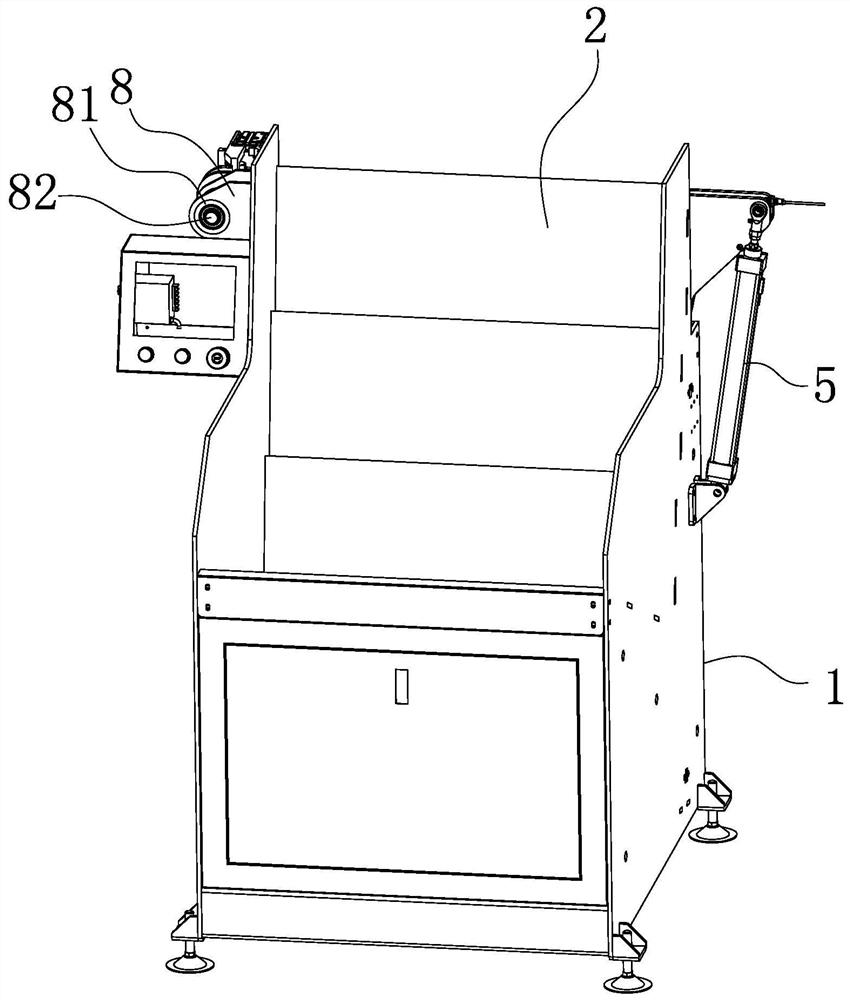

[0041] like Figure 1-8 One of the hoisting machines, including the housing 1 having the tank 11, and the housing 1 is located at the tank 11, which is provided with a stepped distribution, and the entire stepped base 2 is inclined distribution. of. The base 2 is composed of three step plates, and the bottom of the first step plate is located in the tank 11, and the movable plate 3 that can be up and down at the bottom of the tank 11, the highest bit movement of the movable plate 3 allows the movable plate 3 The upper end face is flushed to the upper end of the first step plate, and the minimum displacement distance of the movable plate 3 is flush with the bottom portion of the tank 11, so that when the material groove 11 is loaded into the workpiece, the movable plate 3 lifts and the first line plate. The flushing workpiece scrolls to the upper end of the first step plate under gravity action and stays there. There is also a movable plate 3 between the first step plate and the sec...

Embodiment 2

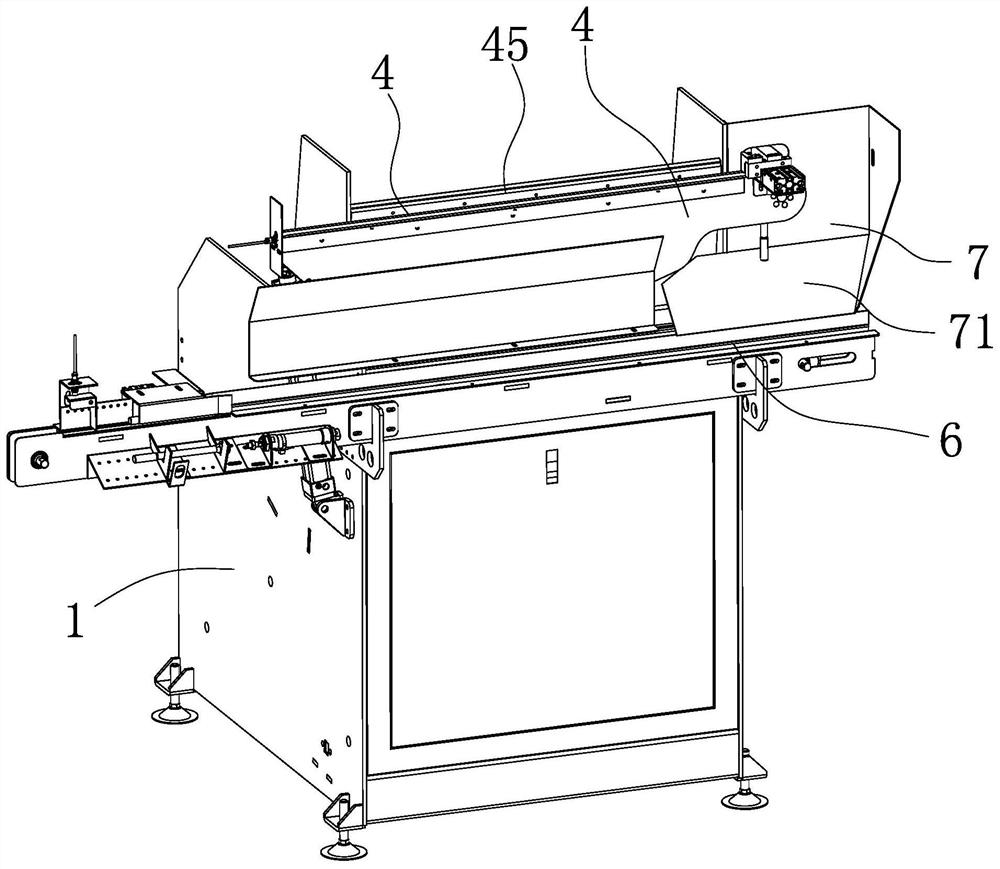

[0047] The structure and principle of the present embodiment are substantially identical, and the feed apparatus in the present embodiment includes a conveyor belt located on the guide rail 4, and the conveyor belt has two strips and respectively located on the left side plate 42 and the right side, respectively. On board 43. By setting the conveyor belt on the left side plate 42 and the right side plate 43 of the guide rail 3, the width of the conveyor belt is the same as the width of the left side plate 42 and the right side plate 43, the conveyor belt is in a state of scrolling, and the workpiece falls in the guide rail. 4 On the first conveyor belt, it can be used to transmit the work of the workpiece dropped on the guide rail 4, which effectively improves the feed efficiency of the lift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com