Dehydration device for 3D printing consumables

A technology of 3D printing and dehydration device, applied in the direction of 3D object support structure, additive processing, additive manufacturing, etc., can solve the problems affecting the feeding of consumables, bubbles on the surface of products, people's troubles, etc. The effect of reducing the production rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

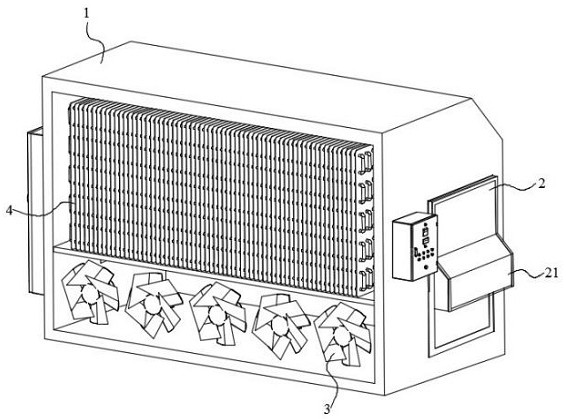

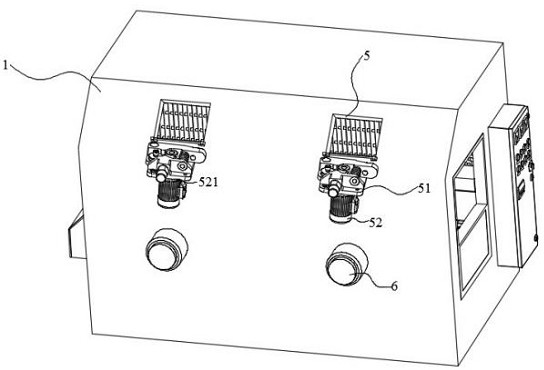

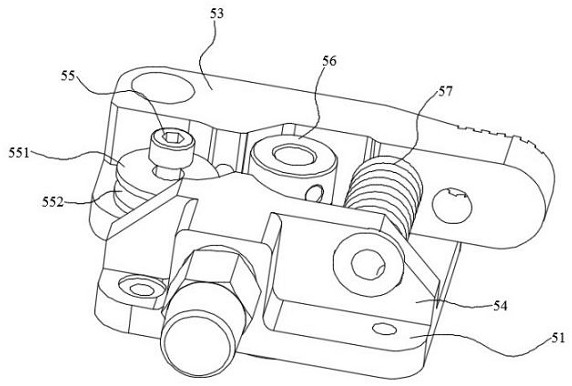

[0019] Embodiment 1: The present invention provides a dehydration device for consumables for 3D printing, including: a heat-insulating shell 1 and a ventilation frame 2 fixed on one side of the heat-insulating shell 1, and one side of the surface of the heat-insulating shell 1 There are two sets of discharge structures 5; one side of the heat-insulating shell 1 is fixed with a heating sheet 4, and the surface of the heat-insulating shell 1 on the side of the heat-insulating shell 1 is fixed with fans 3 at equal intervals, and the ventilation frame 2 is provided with a dehumidifier box 21 on one side, and two sets of consumable positioning plates 6 are fixed on one side of the heat insulation shell 1; the linear consumables set on the surface of the two sets of consumable positioning plates 6 will pass through the fan 3 The hot air flow of the heating sheet 4 raises the internal temperature and evaporates the internal water, and the water vapor is stored inside the dehumidificat...

Embodiment 2

[0020] Embodiment 2: The present invention provides a dehydration device for consumables for 3D printing, including: a heat-insulating shell 1 and a ventilation frame 2 fixed on one side of the heat-insulating shell 1, and one side of the surface of the heat-insulating shell 1 There are two sets of discharge structures 5; one side of the heat-insulating shell 1 is fixed with a heating sheet 4, and the surface of the heat-insulating shell 1 on the side of the heat-insulating shell 1 is fixed with fans 3 at equal intervals, and the ventilation frame 2 is provided with a dehumidifier box 21 on one side, and two sets of consumable positioning plates 6 are fixed on one side of the heat insulation shell 1; the linear consumables set on the surface of the two sets of consumable positioning plates 6 will pass through the fan 3 The hot air flow of the heating sheet 4 raises the internal temperature and evaporates the internal water, and the water vapor is stored inside the dehumidificat...

Embodiment 3

[0021] Embodiment 3: The present invention provides a dehydration device for consumables for 3D printing, including: a heat-insulating shell 1 and a ventilation frame 2 fixed on one side of the heat-insulating shell 1, and one side of the surface of the heat-insulating shell 1 There are two sets of discharge structures 5; one side of the heat-insulating shell 1 is fixed with a heating sheet 4, and the surface of the heat-insulating shell 1 on the side of the heat-insulating shell 1 is fixed with fans 3 at equal intervals, and the ventilation frame 2 is provided with a dehumidifier box 21 on one side, and two sets of consumable positioning plates 6 are fixed on one side of the heat insulation shell 1; the linear consumables set on the surface of the two sets of consumable positioning plates 6 will pass through the fan 3 The hot air flow of the heating sheet 4 raises the internal temperature and evaporates the internal water, and the water vapor is stored inside the dehumidificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com