Molding device and preparation method for PVC drainage pipe production

A molding device and a technology of a production method, which are applied in the field of molding devices for PVC drainage pipe production and their preparation, can solve the problems of large floor space, reduce device production efficiency, and increase production costs, so as to reduce floor space and improve cooling. effect, the effect of improving the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0059] A preparation method of a PVC drainage pipe, the production method comprising the following steps: preparing raw materials, configuring auxiliary agents, stirring and mixing, extruding a mold, and cooling and forming;

[0060] Step A. Prepare raw materials: 120 parts by weight of synthetic PVC resin particles, and the particle diameter of the synthetic PVC resin particles is between 0.8mm-1.1mm;

[0061] Step B. Auxiliary configuration: 4-10 parts of stabilizer, 3-11 parts of lubricant, 5-13 parts of deodorant adsorbent, 6-12 parts of fragrance, 7-10 parts of whitening agent;

[0062] Step C. Stirring and mixing: mix the materials obtained in step A with the five additives in step B, and stir and mix with a stirring device. The stirring time is 2 hours. During the stirring and mixing process, you can Add other additives and solutions as appropriate; after stirring and mixing, material a is formed;

[0063] Step D. Conveying and feeding: injecting material a into the ho...

specific Embodiment approach 2

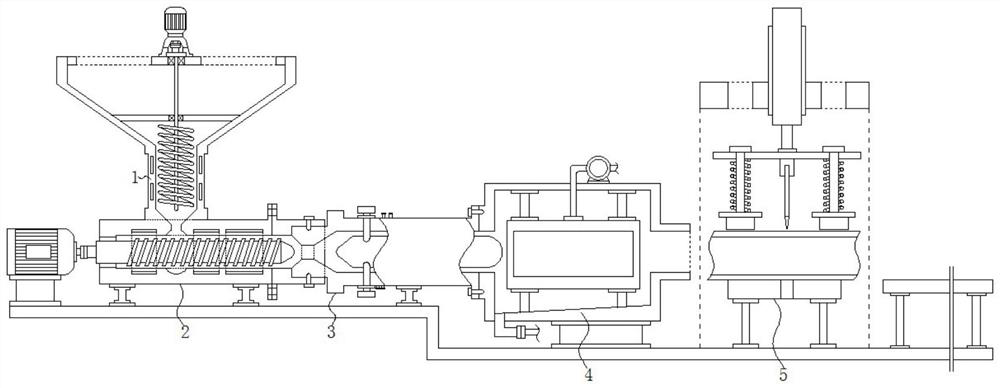

[0067] Specific implementation method two: please refer to Figure 1-14 : A molding device for PVC drainage pipe production, comprising: a feeding device 1, an extrusion device 2, a molding device 3, a cooling device 4 and a cutting device 5;

[0068] The extrusion device 2 is fixedly installed at the bottom of the feeding device 1, and the molding device 3 is fixedly installed on the right side of the extrusion device 2, and the cooling device 4 is fixedly installed on the right side of the molding device 3, and the right side of the cooling device 4 is installed There is a cutting device 5;

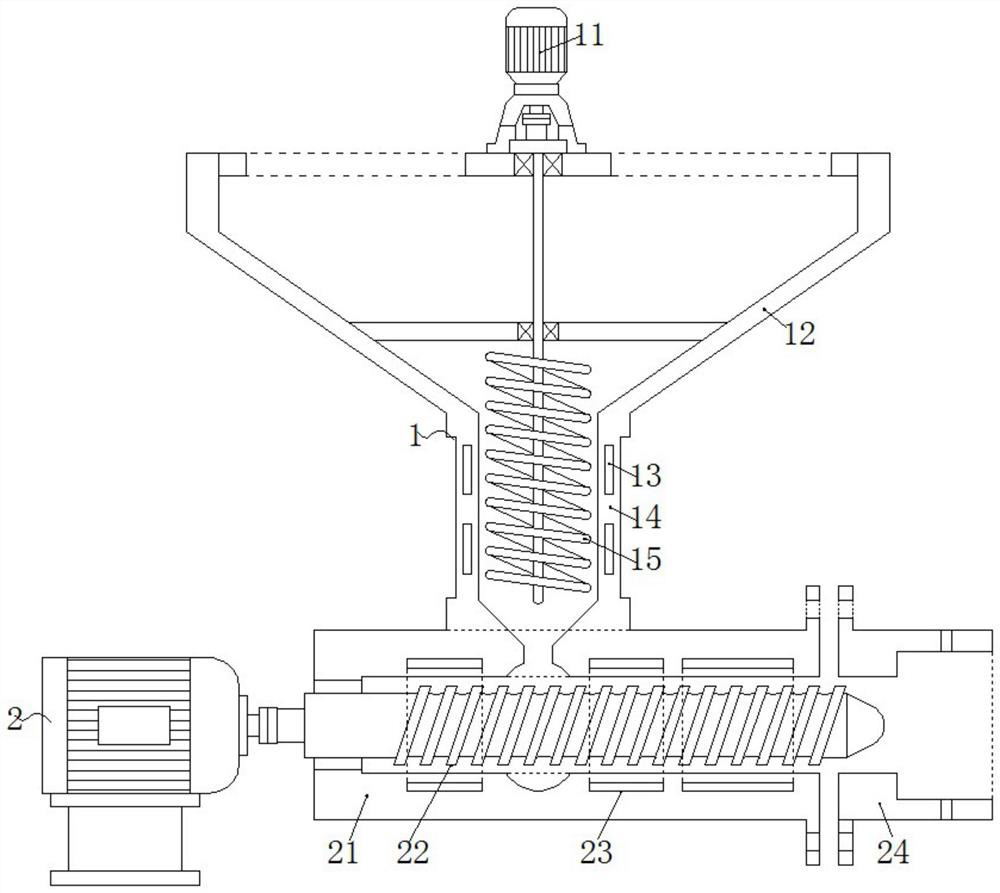

[0069] The feeding device 1, the upper end of the hopper 12 of the feeding device 1 is fixedly provided with a drive motor 11, and the output shaft of the drive motor 11 is fixedly arranged with the discharge dragon 15, and the discharge dragon 15 is arranged inside the feed channel 14;

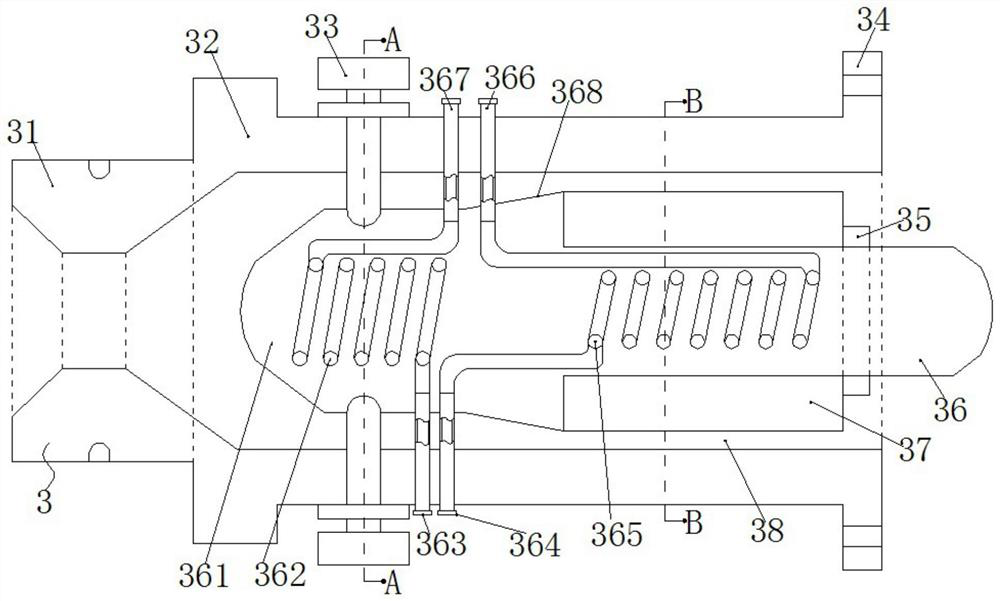

[0070] An extrusion rod 22 is installed inside the extrusion cylinder 21 of the extrusion device 2...

specific Embodiment approach 3

[0075] Specific implementation mode three: this implementation mode is a further limitation of specific implementation mode two, such as Figure 1-2 As shown, the feeding device 1 includes a driving motor 11, a hopper 12, a first heating plate 13, a feeding channel 14 and a discharge dragon 15, and the bottom of the feeding channel 14 is communicated with the feeding port of the extrusion cylinder 21, and at the same time The upper end of the feeding channel 14 is welded and fixed to the hopper 12 , and the inner wall of the feeding channel 14 is fixedly provided with a first heating plate 13 .

[0076] The discharge dragon 15 rotates under the action of the driving motor 11. At this time, the molten material inside the hopper 12 is injected into the inside of the extrusion barrel 21 under the action of the discharge dragon 15. The inner wall of the extrusion barrel 21 is installed with a second The heating plate 23 is used to prevent the material inside the extruding cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com