Self-adaptive scaling platform applied to multi-size POL laser cutting

An adaptive scaling and laser cutting technology, which is applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of frequent manual platform replacement, prolonged production time, and increased production costs of enterprises, so as to avoid manual replacement platform, shorten processing time, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

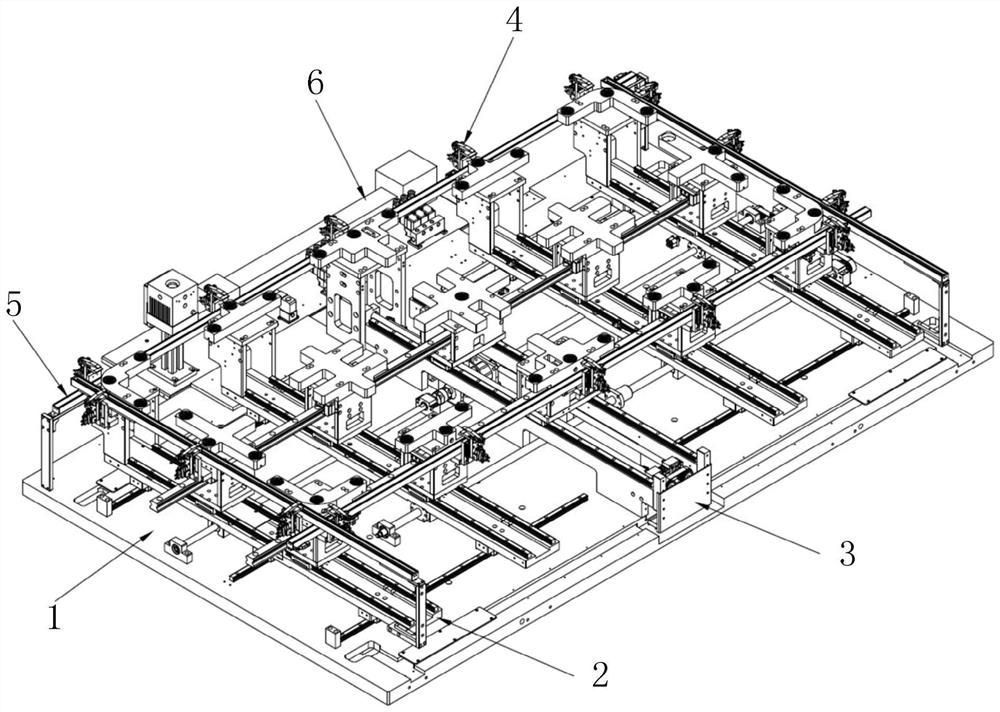

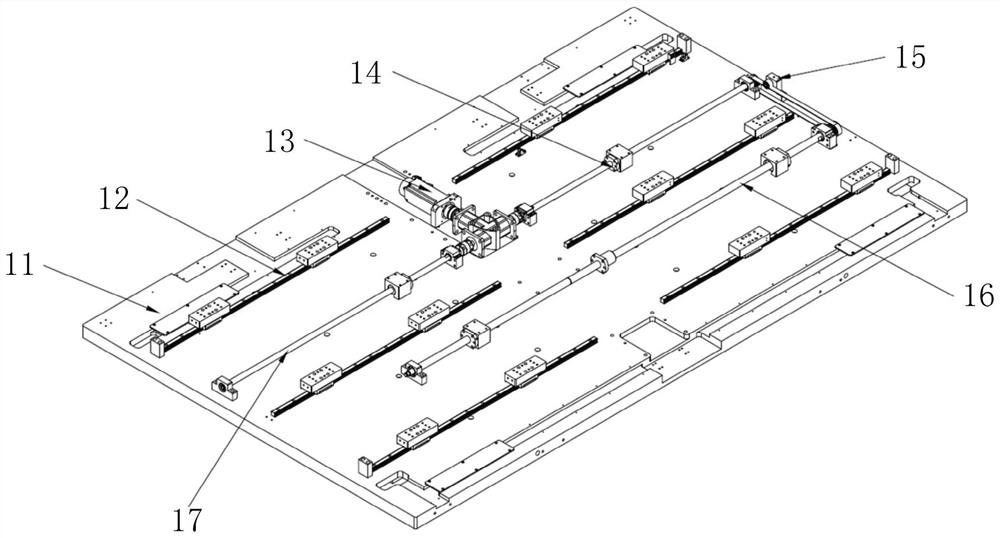

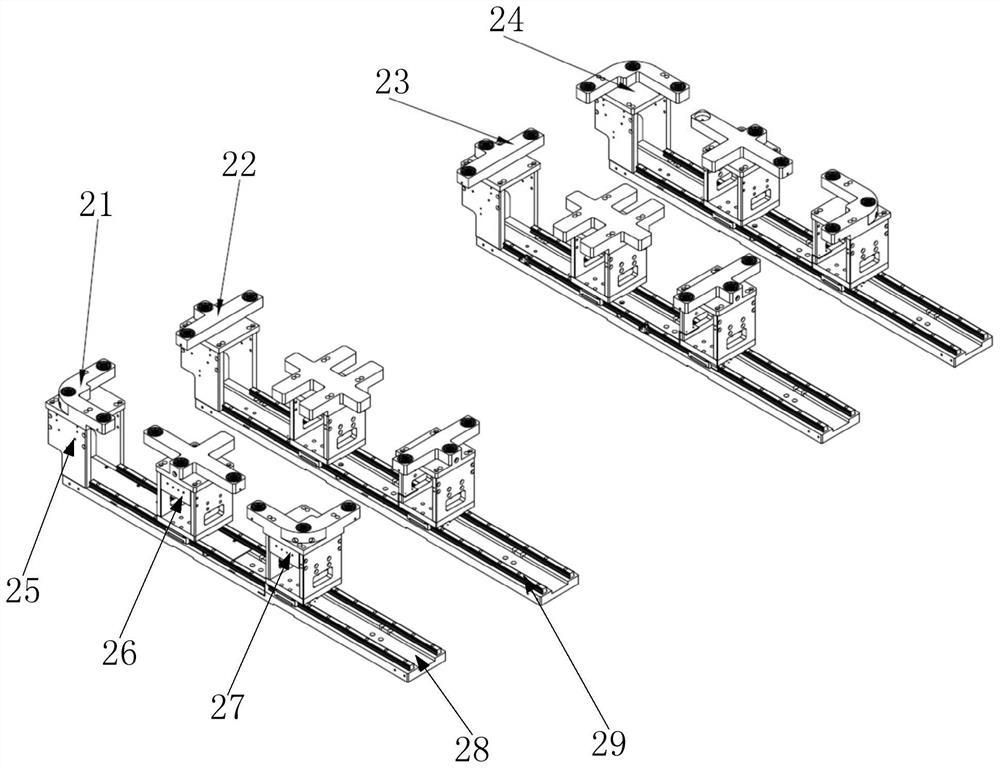

[0054] Such as Figure 1 to Figure 7 as shown,

[0055] An adaptive scaling platform applied to multi-size POL laser cutting, including X-axis transmission assembly 1, Y-axis slide module 2, Y-axis transmission assembly 3 and waste clamping assembly 4, Y-axis slide module 2 and Y-axis transmission assembly 3 are installed on the X-axis transmission assembly 1, the Y-axis transmission assembly 3 is located in the middle of the X-axis transmission assembly 1 along the X-axis direction, and the waste clamping assembly 4 is evenly distributed on the Y-axis slide module 2 and the Y-axis transmission assembly 3, the X-axis transmission assembly 1 drives the Y-axis skateboard module 2 to drive and connect in the X-axis direction, and the Y-axis transmission assembly 3 is connected to the Y-axis skateboard module 2 through the linkage slider guide rail assembly.

[0056] Preferably, the X-axis transmission assembly 1 includes a fixed base plate 11 and a motor deceleration unit 13. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com