Crushing and grinding device for medicine production

A grinding device and drug technology, which is applied in the direction of making drugs into special physical or ingestible devices, grain processing, solid separation, etc., can solve the problems of reducing the quality of drug production and processing, inconvenient materials to be fully crushed and ground, and achieve structural Simplicity, improved processing quality, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

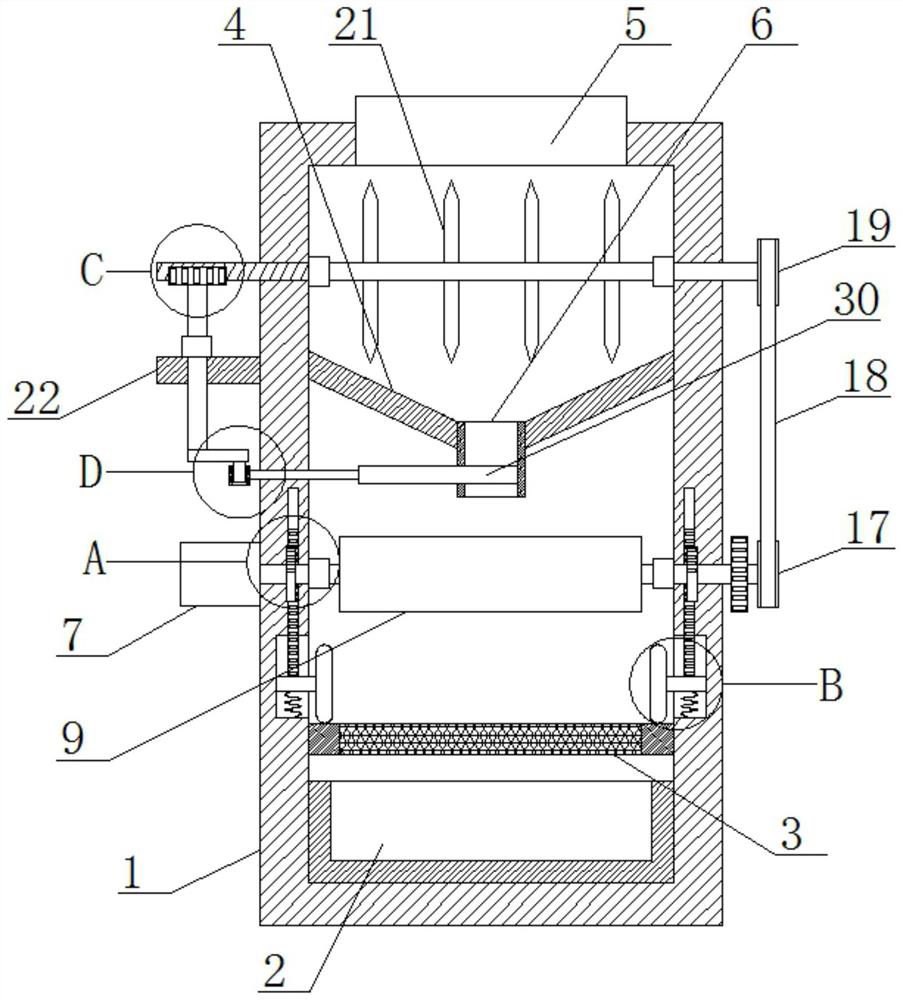

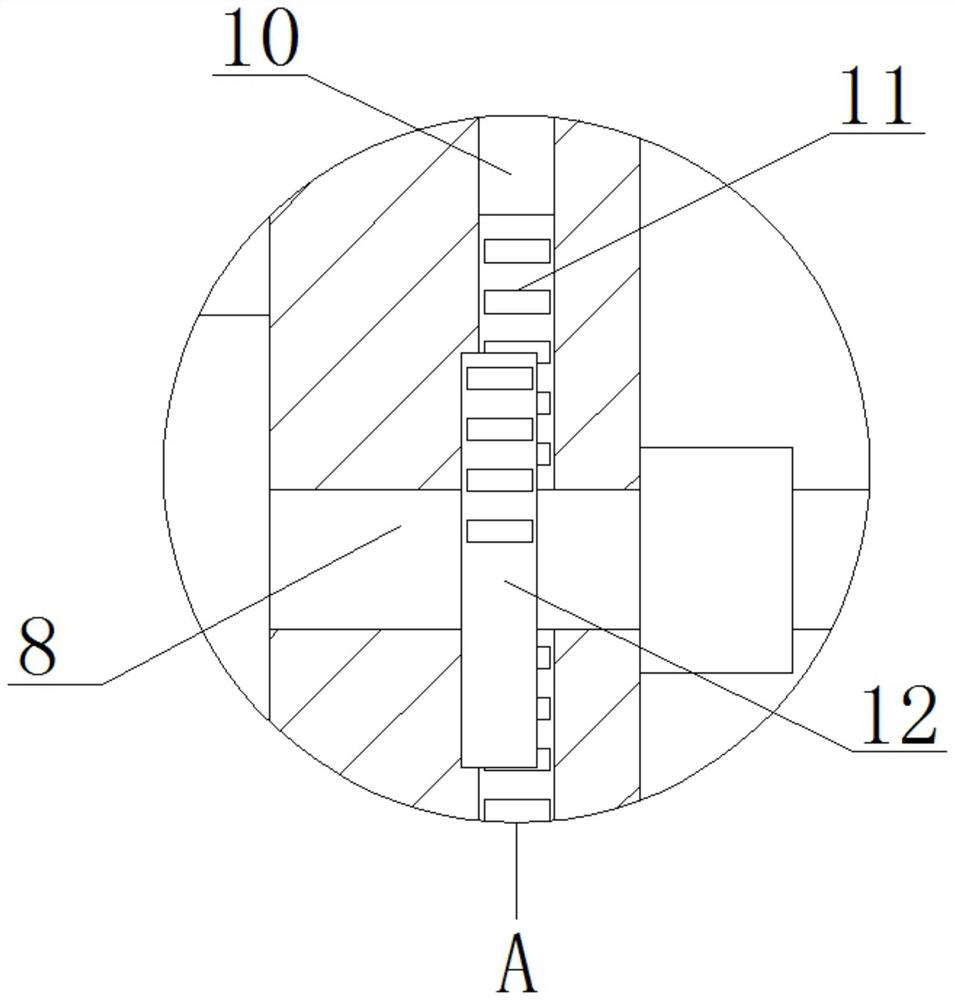

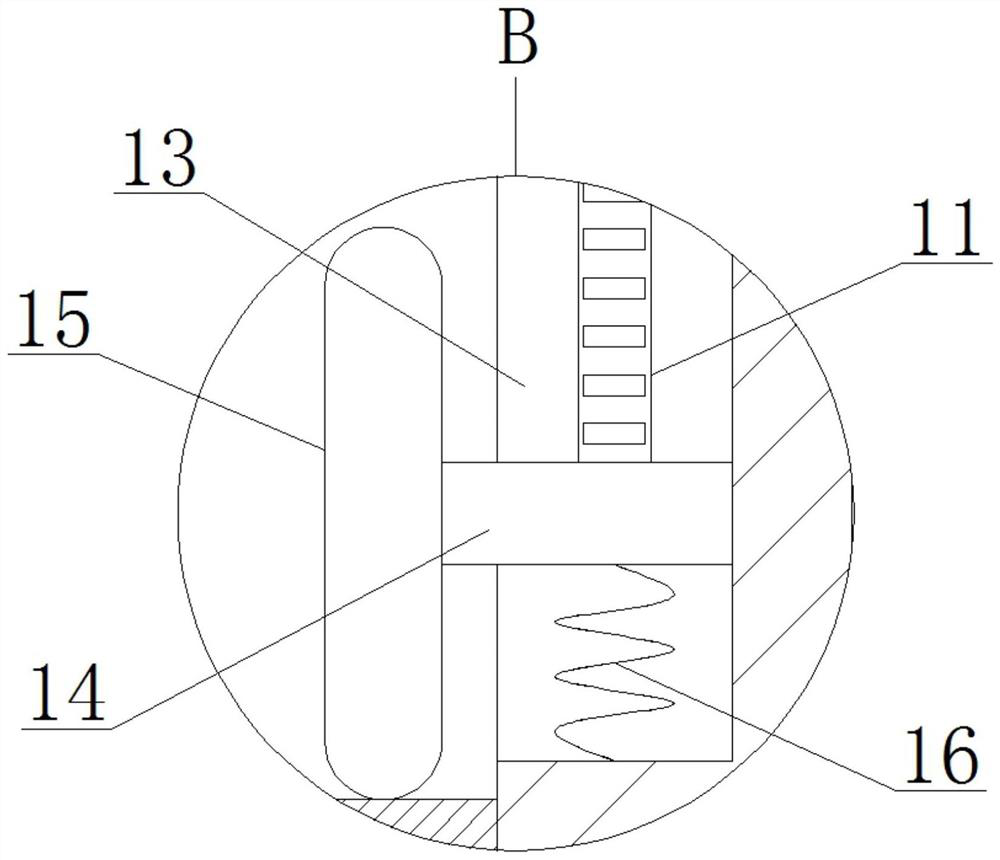

[0029] refer to Figure 1-7 , a crushing and grinding device for drug production, comprising a housing 1, the top of the housing 1 is provided with a feed inlet 5, a collection box 2 is placed on the inner wall of the bottom of the housing 1, and a sieve plate 3 is fixedly installed in the housing 1, A funnel 4 is fixedly installed in the housing 1, and a discharge port 6 is opened at the bottom of the funnel 4. Two symmetrical first through holes are opened on both sides of the housing 1, and the same A first rotating shaft 8, the outer sides of the two first rotating shafts 8 are fixedly provided with grinding rollers 9, and the two grinding rollers 9 are meshed, and the inner walls of both sides of the housing 1 are provided with first chute 13, and the two second The top inner wall of a chute 13 is provided with a mounting groove 10, and the two mounting grooves 10 communicate with the two first through holes respectively, and a rack 11 is slidably installed in the two mou...

Embodiment 2

[0038] refer to Figure 1-7, a crushing and grinding device for drug production, comprising a housing 1, the top of the housing 1 is provided with a feed inlet 5, a collection box 2 is placed on the inner wall of the bottom of the housing 1, and a sieve plate is fixed and installed in the housing 1 by bolts 3. A funnel 4 is fixedly installed in the housing 1 by welding. The bottom of the funnel 4 is provided with a discharge port 6. Both sides of the housing 1 are provided with two symmetrical first through holes. The same first rotating shaft 8 is installed in rotation, and the outer sides of the two first rotating shafts 8 are fixedly sleeved with grinding rollers 9 through welding, and the two grinding rollers 9 are engaged with each other. Slot 13, the top inner walls of the two first chute 13 are provided with installation grooves 10, the two installation grooves 10 communicate with the two first through holes respectively, racks 11 are slidingly installed in the two inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com