Sludge Treatment Equipment

A sludge treatment and equipment technology, applied in the field of sludge treatment equipment, can solve the problems of difficult control of the amount of treatment liquid entering, shortened service life of mechanical valves, accumulation of sediments, etc. The effect of liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

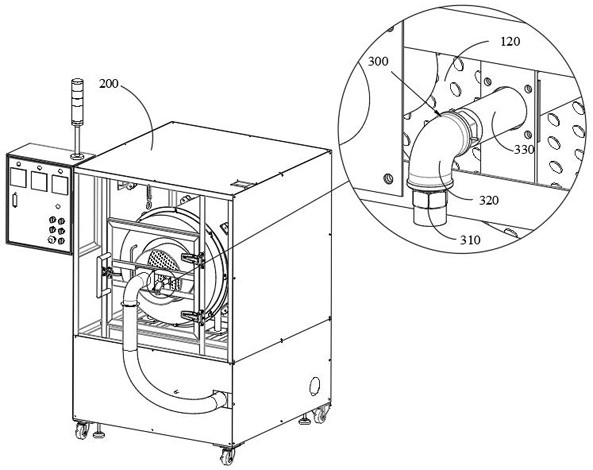

[0055] see figure 1 , this embodiment provides a sludge treatment equipment including a housing 200, a treatment liquid feeding device 300, and a sludge treatment system; the sludge treatment system is arranged in the housing 200; the treatment liquid feeding device The device 300 communicates with the inner cavity of the centrifugal cylinder 120 of the sludge treatment system after passing through the housing 200; the treatment liquid feeding device includes a treatment liquid interface 310, a pneumatic liquid inlet valve 320 and a liquid inlet pipe 330 The pneumatic liquid inlet valve 320 is connected between the processing liquid interface 310 and the liquid inlet pipe 330 ;

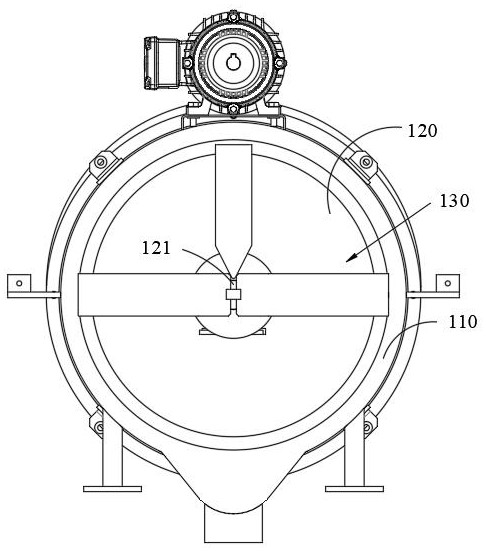

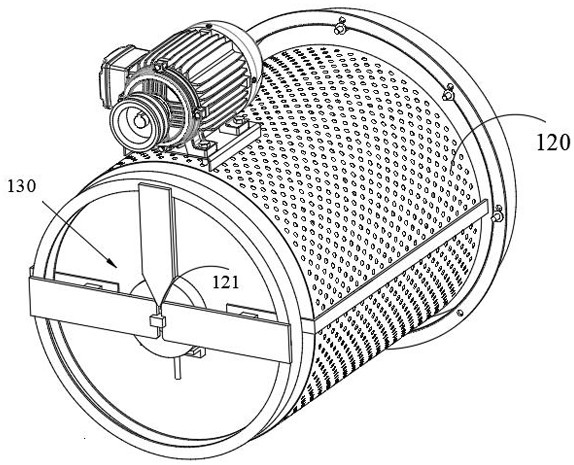

[0056] see figure 2 and image 3 , the present embodiment 1 provides a sludge treatment system, including a receiving cylinder 110, a centrifugal cylinder 120 and a cleaning device 130; the centrifugal cylinder 120 is sleeved in the receiving cylinder 110; the cleaning device 130 sets It is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com