Compressed air energy storage lining cavern sealed by integral rubber capsule

A technology of compressed gas energy storage and rubber bladder, which is applied in the fields of adjustable capacity gas storage tanks, gas processing/storage effects, gas/liquid distribution and storage, etc., to achieve high economic benefits, good sealing effects, and low risks and costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

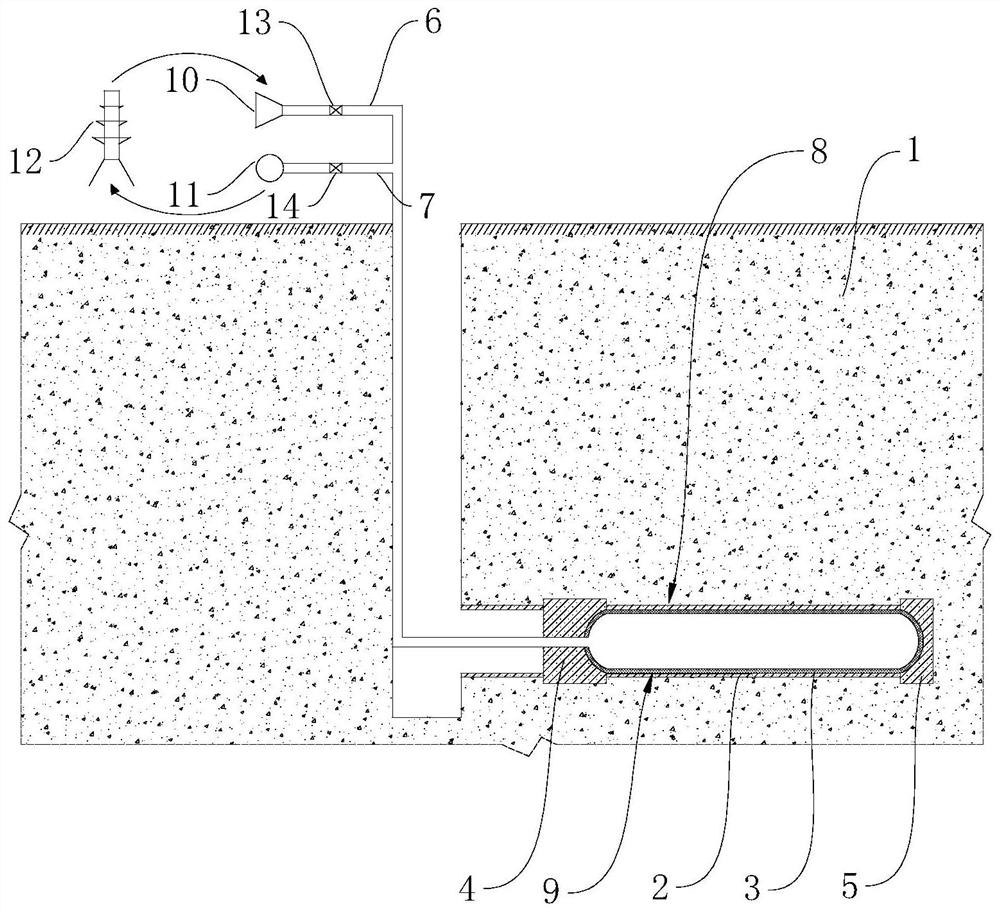

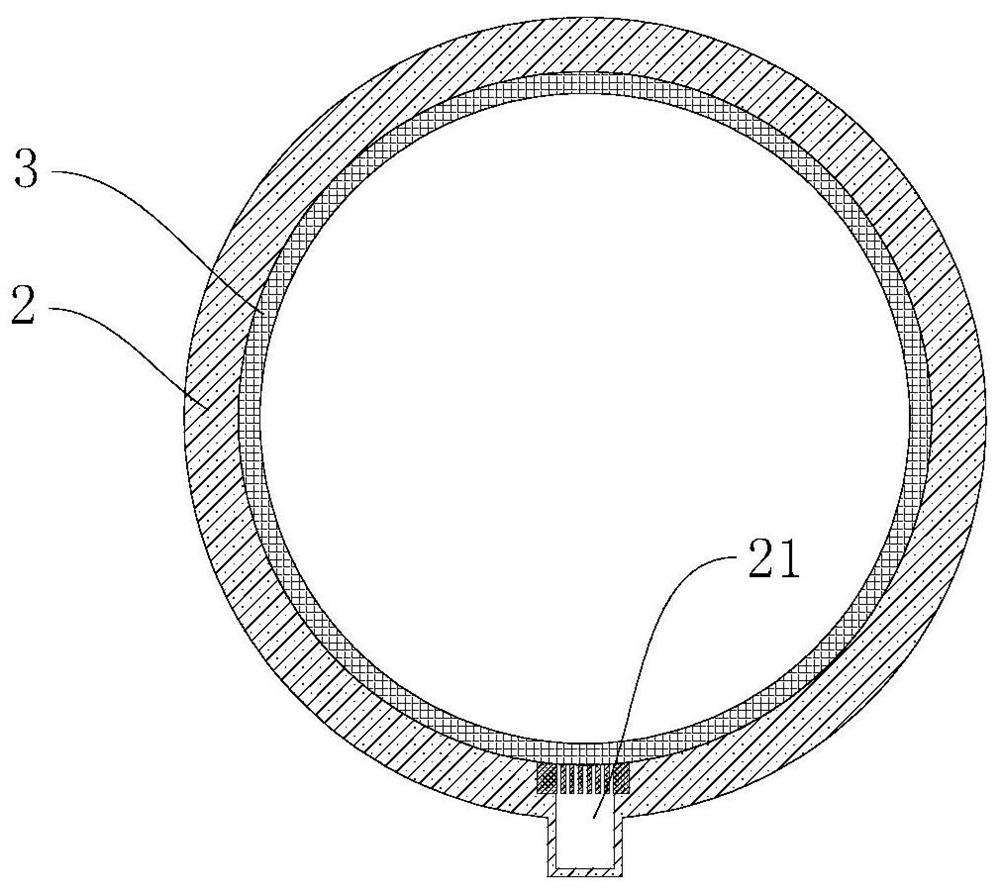

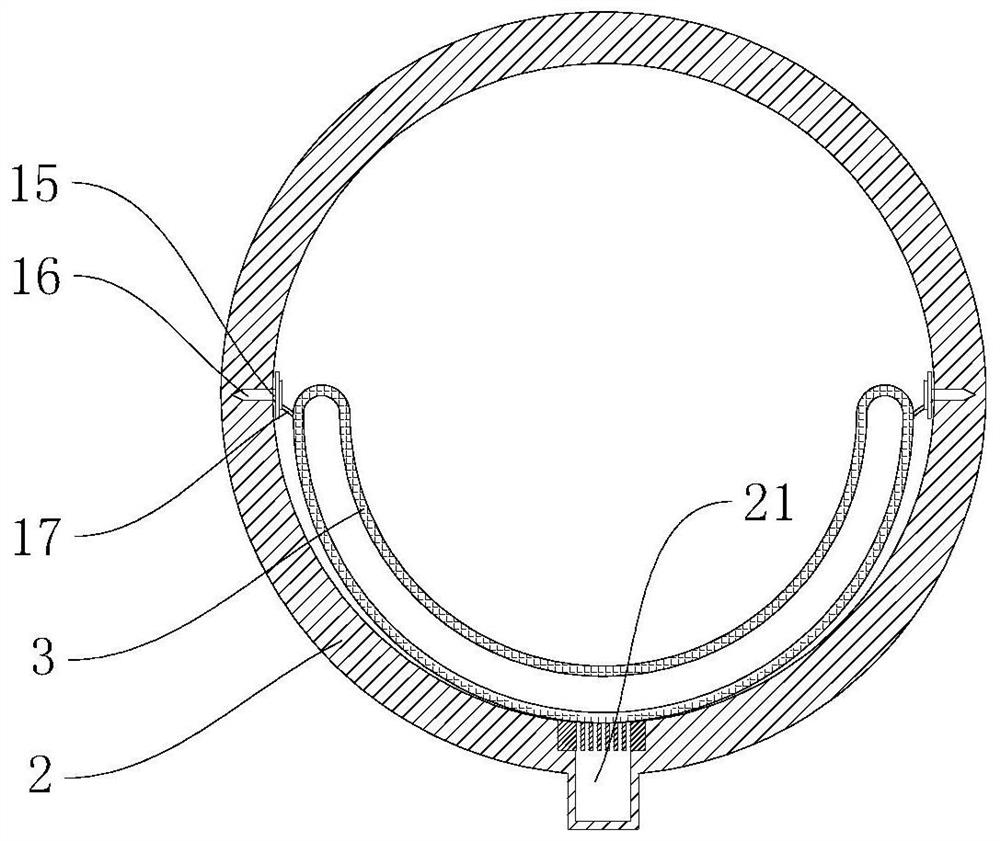

[0024] The compressed air energy storage liner cavity sealed by the integral rubber bag of embodiment 1, such as Figure 1 to Figure 3 As shown, it includes the compressed gas storage lining cavern 8, the integral rubber bladder 3 and the drainage ditch 21. The compressed gas storage lining cavern 8 is excavated in the surrounding rock 1 with good integrity, and the integral rubber bladder 3 is set In the compressed gas storage lined cavern 8, the drainage ditch 21 is excavated at the bottom of the compressed gas storage lined cavern 8, and the integral rubber bag 3 is used for sealing the compressed gas storage lined cavern 8, and the integral rubber bag 3 When inflated, it is closely attached to the lining wall of the compressed gas storage lining cave 8; during the inflation process, the integral rubber bag 3 is closely attached to the lining wall of the compressed gas storage lining cave 8, and the internal pressure is transmitted to the surrounding rock 1 , the reaction o...

Embodiment 2

[0029] The difference between the compressed air energy storage liner cavity sealed by the integral rubber bag of Example 2 and Example 1 is that in Example 2, as Figure 4 As shown, the inner wall of the reinforced concrete layer 2 is laid with a layer of geotextile layer 18, and the geotextile layer 18 is fixed on the inner wall of the reinforced concrete layer 2 by a number of cement nails 19, and each cement nail 19 and the geotextile layer 18 are compacted and arranged There are spacers 20.

[0030] After the construction of the above-mentioned compressed air energy storage lining cavern, during the inflation process, the air compressor 10 uses the surplus electric energy in the power grid 12 to compress the air in the atmosphere, and the compressed gas enters the integral rubber bag 3 along the intake pipe 6, and the overall The rubber bladder 3 expands under the action of gas pressure. When the integral rubber bladder 3 is fully inflated, the integral rubber bladder 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com