EGR cooler cooling temperature control device and method

An EGR cooler, cooling temperature technology, applied in the charging system, machine/engine, engine components, etc., can solve the problems of inability to accurately and automatically control the exhaust gas temperature, poor reliability of the temperature control device, and poor control of the cooling temperature, etc. To achieve the effect of convenient installation, use and replacement, low cost, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific description will be given below in conjunction with specific embodiments.

[0033] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

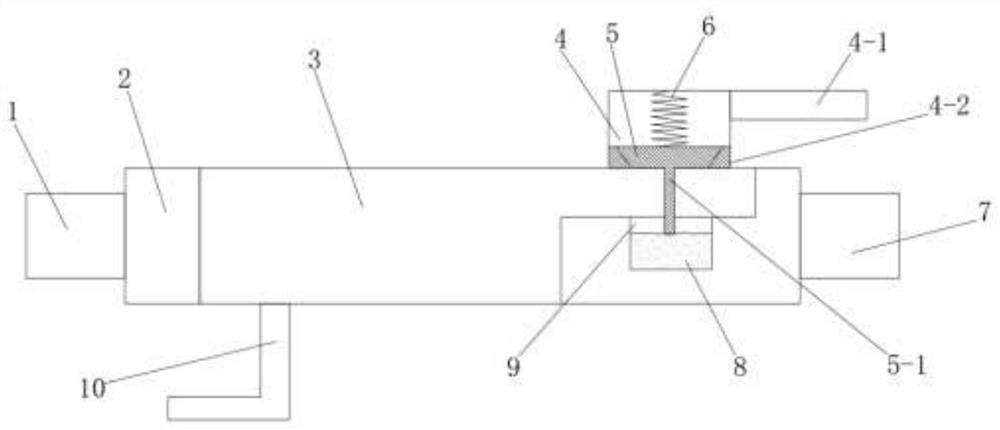

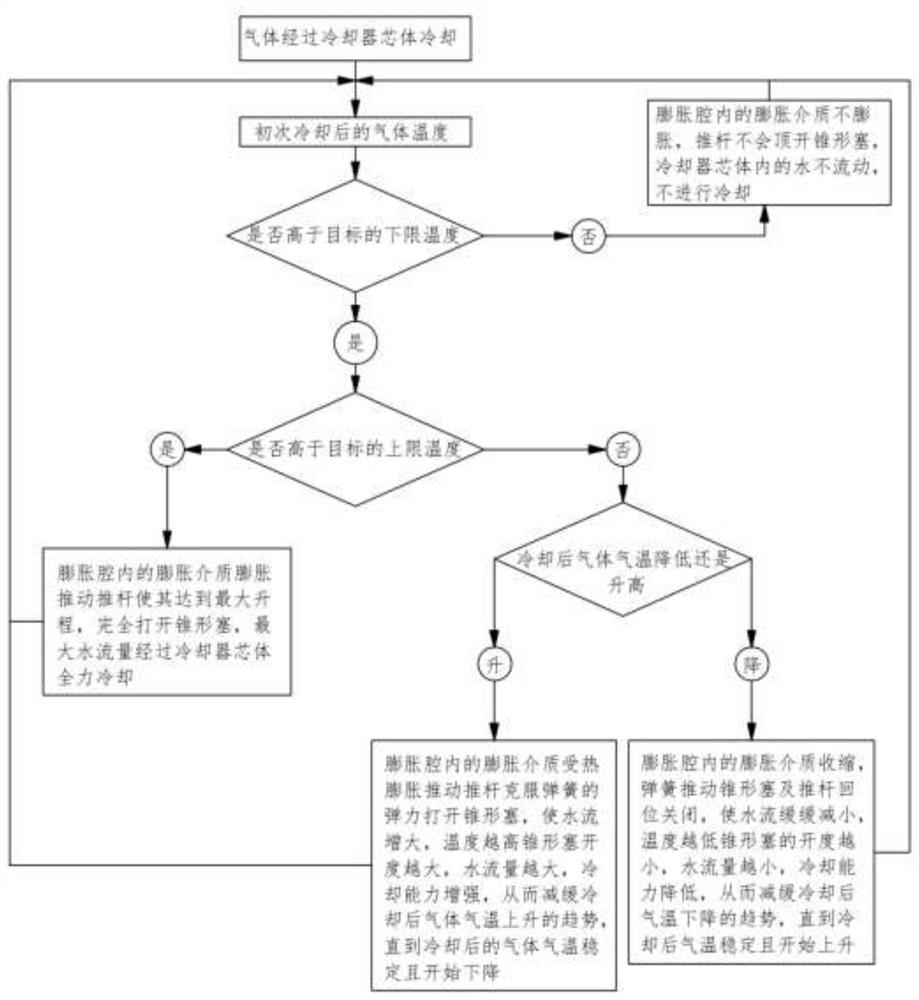

[0034] like figure 1 As shown, a cooling temperature control device for an EGR cooler, a cooler shell 2 and a cooler core 3, the left end of the cooler shell 3 is provided with an air inlet 1, and the right end is provided with an air outlet 7, the cooler The shell 2 is provided with an air conditioner core 3, and the bottom of the cooler shell 2 is provided with a round hole, and a water inlet pipe 10 is arranged in the round hole, and the water inlet pipe 10 is connected with the bottom of the cooler core 3, and the cooler core 3 is provided with a temperature control device, the temperature control device includes a sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com