Prefabricated part connecting device, prefabricated part assembly and assembling method

A technology of prefabricated components and connecting devices, which is applied in the construction of buildings, construction, and the processing of building materials, can solve the problems of complicated connection operations, and achieve the effects of reliable connection, low cost and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

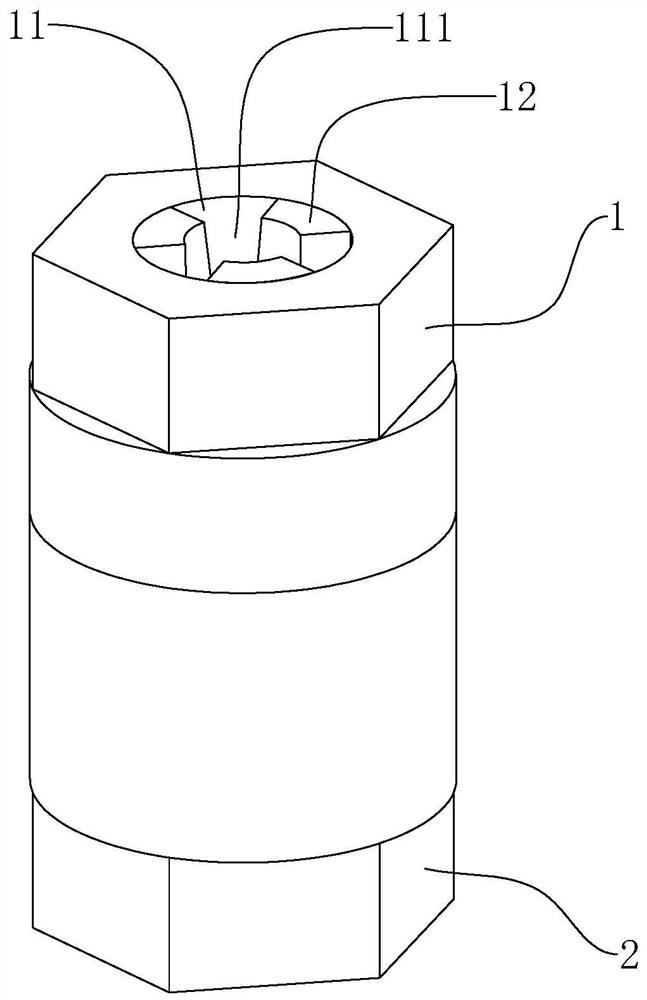

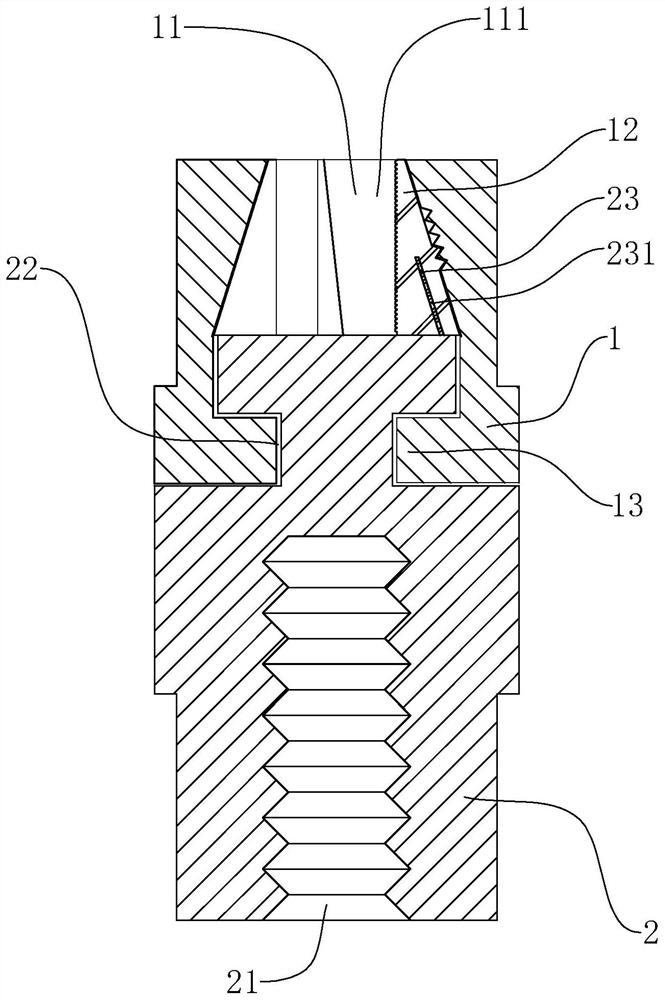

[0046] refer to figure 1 , Embodiment 1 of the present application discloses a prefabricated component connection device, including a clamping part 1 and a locking part 2, and the prefabricated component connection device is mainly used for vertical connection of prefabricated components.

[0047] refer to figure 2 , the lower surface of the clamping piece 1 abuts against the upper surface of the locking piece 2, and the clamping piece 1 is used to clamp the overhanging steel bar of the upper component, so that the connecting device is fixedly connected with the upper component; the locking piece 2 can pass through The outstretched steel bars of the lower component are locked in a thread fit manner, so that the connecting device is fixedly connected with the lower component.

[0048] refer to figure 1 , in this embodiment, the lower part of the locking member 2 is a regular hexagonal prism, which is convenient for screwing operation during screw connection. In other embodim...

Embodiment 2

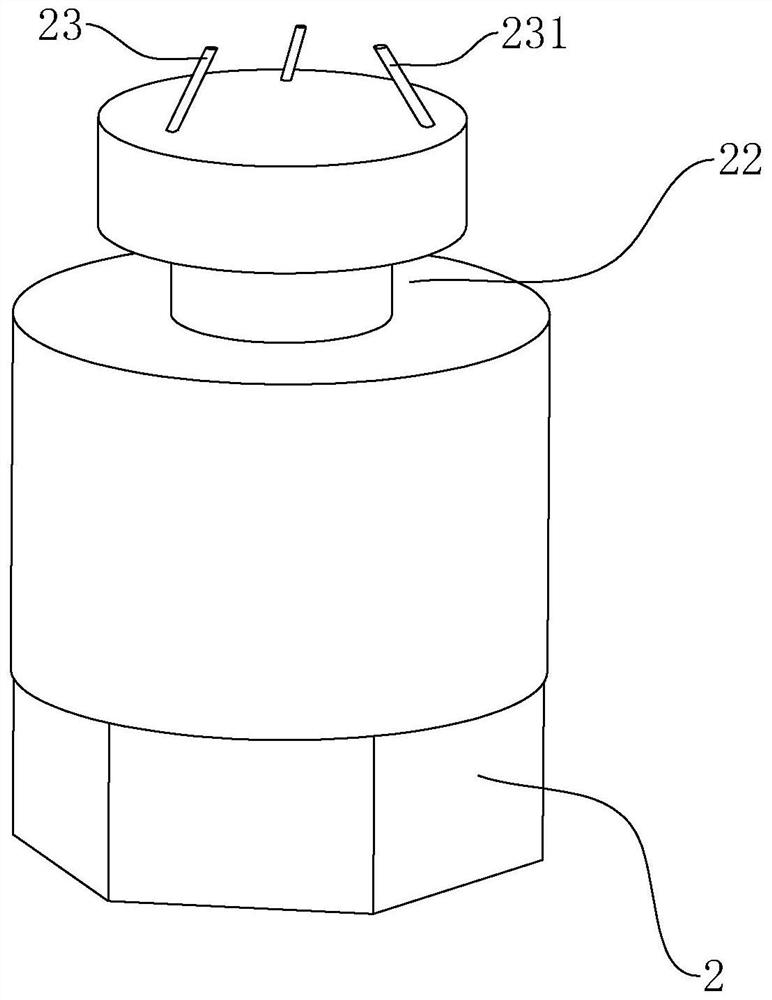

[0057] refer to Figure 5 and Image 6 The difference between this embodiment and Embodiment 1 is that the upper surface area of the accommodating groove 11 is larger than the lower surface area, the inclination direction of the side wall of the accommodating groove 11 changes, and the surface of the clamping block 12 matched with the side wall of the accommodating groove 11 The direction of inclination also changes accordingly; and the upper part of the fixed column 231 is uniformly inclined to the direction away from the axis of the mounting hole 21. Correspondingly, the inclination direction and angle of inclination of the oblique hole 121 need to be consistent with the fixed column 231, so it also follows the direction of the fixed column. 231 is changed; and in this embodiment, the initial position of the clamping block 12 is at the upper part of the accommodating groove 11 , and the upper surface of the clamping block 12 is flush with the upper surface of the clamping ...

Embodiment 3

[0060] refer to Figure 7 and Figure 8 , The difference between this embodiment and Embodiment 1 is that the depth of the locking groove 22 gradually increases along the direction approaching the mounting hole 21 . The design of the locking groove 22 in this embodiment can reduce the contact area between the locking member 2 and the positioning portion 13 compared with the first embodiment, and the frictional force is correspondingly reduced, which is beneficial to the rotation of the clamping member 1 .

[0061] refer to Figure 9 , the present application discloses a prefabricated component assembly, including a first component 3, a second component 4, and the prefabricated component connecting device as in Embodiment 1. The first component 3 is located on the upper part of the entire assembly, and the bottom of the first component 3 has a partially protruding first steel bar 31. The integrity with the first member 3 is strong, and the force is continuous. The first ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com