Preparation method of diatomite tailing thermal insulation coating

A technology for thermal insulation coatings and diatomite tailings, which is applied in fire-resistant coatings, coatings, etc., to achieve significant social benefits, overcome ecological problems, and achieve high-value utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

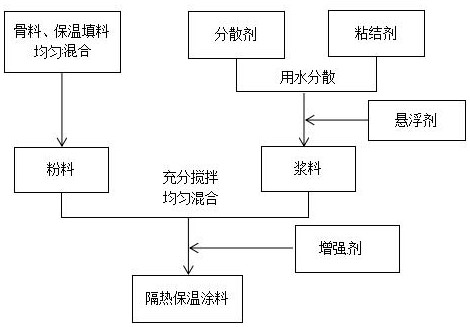

Method used

Image

Examples

Embodiment 1

[0016] Mix 60 parts of 100-mesh diatomite tailings, 30 parts of bauxite, and 10 parts of floating beads to make mixed aggregate powder. After dispersing 8 parts of phosphoric acid, 4 parts of attapulgite, and 0.5 parts of sodium hexametaphosphate with water, add 0.5 parts of reinforcing agent, appropriate amount of water and mixed aggregate powder, and mix uniformly to form a paste coating. Algae tailings thermal insulation coating.

[0017] Diatom tailings thermal insulation coating also has good physical and chemical properties: after the coating is naturally dried, the surface appearance is good and there is no crack; The suspension rate of the paint is 97.5%; the relative viscosity is 1.56; the surface dry time and solid dry time of the paint are 30min and 147min respectively. The thermal insulation coating prepared from diatom tailings thermal insulation coating has good heat resistance: when the service temperature is 285°C and the coating thickness is 8mm, the best hea...

Embodiment 2

[0019] Mix 100 parts of diatomite tailings over 100 meshes, 50 parts of calcined kaolin and 15 parts of floating beads to make mixed aggregate powder. After dispersing 15 parts of aluminum dihydrogen phosphate, 8 parts of bentonite, and 1 part of sodium hexametaphosphate with water, add 1 part of reinforcing agent, an appropriate amount of water and mixed aggregate powder, and stir evenly to form a paste coating, which is prepared after packaging. Diatom tailings insulation coating.

[0020] Diatom tailings thermal insulation coating also has good physical and chemical properties: after the coating is naturally dried, the surface appearance is good and there is no crack; The suspension rate of the paint is 97.8%; the relative viscosity is 1.58; the surface dry time and hard dry time of the paint are 31min and 150min respectively. The thermal insulation coating prepared from diatom tailings thermal insulation coating has good heat resistance: when the service temperature is 28...

Embodiment 3

[0022] Mix 100 parts of diatomite tailings over 100 meshes, 50 parts of calcined kaolin and 15 parts of floating beads to make mixed aggregate powder. Add 15 parts of water glass, 8 parts of bentonite, and 1 part of sodium hexametaphosphate to disperse evenly with water, add 1 part of reinforcing agent, appropriate amount of water and mixed aggregate powder, and stir evenly to form a paste coating, which is prepared into diatoms after packaging Tailings insulation coating.

[0023] Diatom tailings thermal insulation coating also has good physical and chemical properties: after the coating is naturally dried, the surface appearance is good and there is no crack; The suspension rate of the paint is 98.0%; the relative viscosity is 1.58; the surface dry time and hard dry time of the paint are 31min and 150min respectively. The thermal insulation coating prepared from diatom tailings thermal insulation coating has good heat resistance: when the service temperature is 285°C and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

| suspension rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com