A kind of quartz fiber reinforced quartz-based composite material and its manufacturing method

A composite material and quartz fiber technology, which is applied in the field of high-temperature-resistant wave-transparent composite material preparation, achieves the effects of simple equipment, wide range of raw materials, and improved densification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for manufacturing a quartz fiber reinforced quartz-based composite material, comprising the following steps:

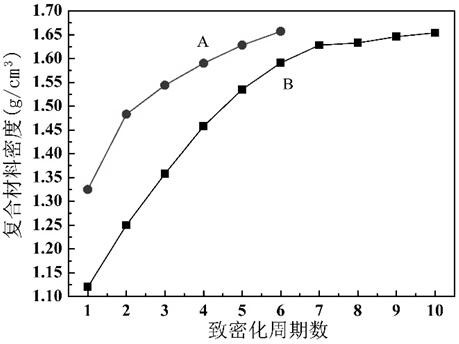

[0042] 1) Preparation of fiber prefabricated parts: Quartz fiber slabs are prepared as prefabricated parts by 2.5D weaving method, the fiber volume fraction is 35%, and the length, width and height are 100mm×100mm×20mm; SiO 2f / SiO 2 The density of the composite material flat plate is required to be 1.65g / cm 3 ;

[0043] Soak the quartz fiber preform in acetone for 10 hours each time, and then dry it in an oven at 100°C for 2 hours to remove the wetting agent and impurities on the surface of the fiber. Repeat "soaking-drying" 3 times, each time Soak and replace with new acetone;

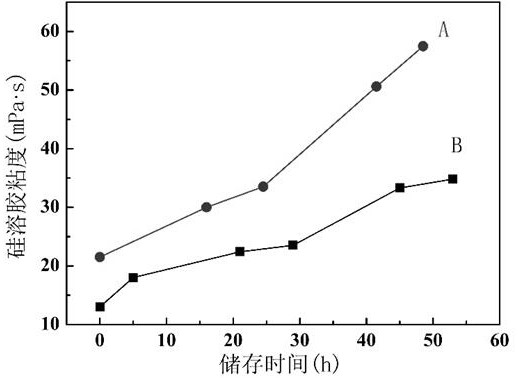

[0044] 2) Pour 2 kg of commercially available acidic silica sol with a solid content of 25%, pH = 2, and a viscosity of less than 10 mPa·s into the flask matched with the rotary evaporator, connect the flask to the rotary evaporator, and evacuate to 6×10 -2 MPa, check the...

Embodiment 2

[0052] A method for manufacturing a quartz fiber reinforced quartz-based composite material, comprising the following steps:

[0053] 1) Preparation of fiber preforms:

[0054] The quartz fiber plate is prepared as a prefabricated part by laying up and suturing, the fiber volume fraction is 50%, and the length, width and height are 100mm×100mm×20mm; SiO 2f / SiO 2 The density of the composite material flat plate is required to be 1.75g / cm 3 ;

[0055] Soak the quartz fiber preform in acetone for 10 hours each time, and then dry it in an oven at 100°C for 2 hours to remove the wetting agent and impurities on the surface of the fiber. Repeat "soaking-drying" 3 times, each time Soak and replace with new acetone;

[0056] 2) Pour 2kg of commercially available acidic silica sol with a solid content of 20%, pH = 4, and a viscosity of less than 10mPa·s into the flask matched with the rotary evaporator, connect the flask to the rotary evaporator, and evacuate to 6×10 -2 MPa, check...

Embodiment 3

[0064] A method for manufacturing a quartz fiber reinforced quartz-based composite material, comprising the following steps:

[0065] 1) Preparation of fiber prefabricated parts: Quartz fiber slabs were prepared as prefabricated parts by 2D puncture, the fiber volume fraction was 45%, and the length, width and height were 100mm×100mm×20mm; SiO 2f / SiO 2 The density requirement of the composite plate is 1.70g / cm 3 ;

[0066] Soak the quartz fiber preform in acetone for 10 hours each time, and then dry it in an oven at 100°C for 2 hours to remove the wetting agent and impurities on the surface of the fiber. Repeat "soaking-drying" 3 times, each time Soak and replace with new acetone;

[0067] 2) Pour 2 kg of commercially available acidic silica sol with a solid content of 23%, pH = 3, and a viscosity of less than 10 mPa·s into the flask matched with the rotary evaporator, connect the flask to the rotary evaporator, and evacuate to 6×10 -2 MPa, check the air tightness, under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com