Food antibacterial treatment machine

A processing machine and food technology, applied in grain processing, irradiation and other directions, can solve the problems of inconvenient sterilization and disinfection, and achieve the effect of avoiding bacterial growth, improving safety and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

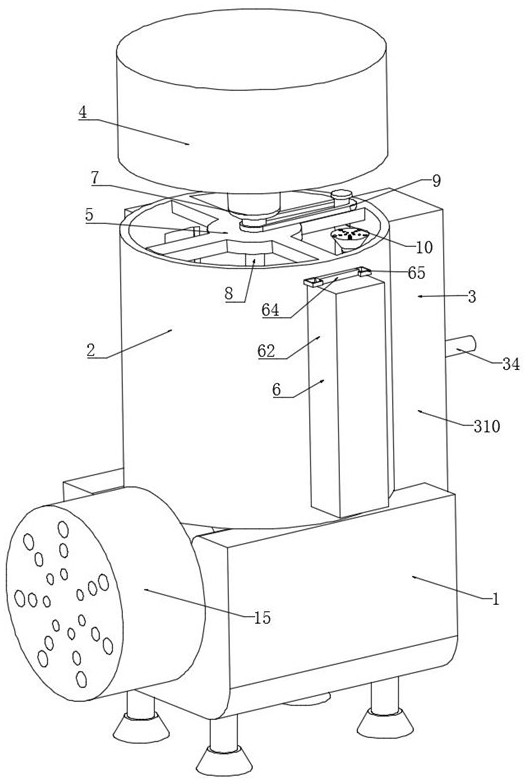

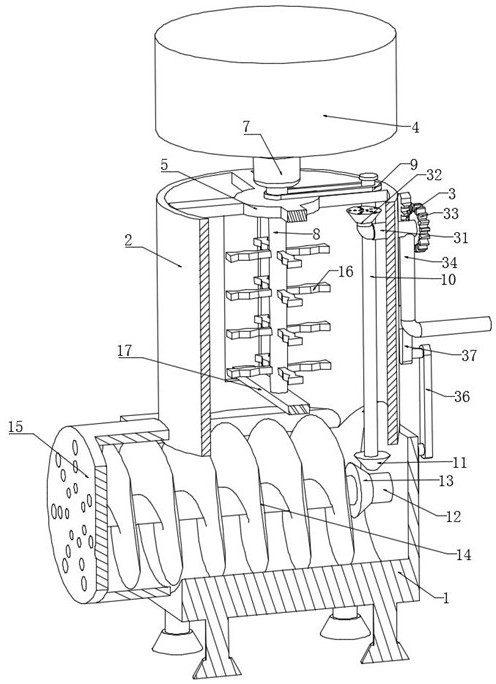

[0028]Embodiment 1: A food antibacterial processing machine, comprising a processing machine 1 and a bucket cover 4, the upper part of the processing machine 1 is fixedly connected with a crushing bucket 2, the right side wall of the grinding bucket 2 is provided with a cleaning mechanism 3, the front and back of the grinding bucket 2 The side walls are all provided with a sterilizing mechanism 6, the upper end surface of the crushing barrel 2 is fixedly connected with a cross support plate 5, and the upper end surface of the cross support plate 5 is fixedly connected with a drive motor 7, and the output shaft of the drive motor 7 runs through the cross support plate 5. The lower end surface is fixedly connected with a rotating shaft 8, and the outside of the rotating shaft 8 is evenly and fixedly connected with a crushing blade 16. The right cavity wall of the processor 1 is rotatably connected with a transmission shaft 12, and the outer wall of the transmission shaft 12 is fix...

Embodiment 2

[0029] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the cleaning mechanism 3 includes a rotating cylinder 31, a nozzle 32, a gear 33, a water distribution pipe 34, a crank 35, a connecting rod 36, a transmission rod 37, a sleeve 38, and a rack 39 and the protective shell 310, the right cavity wall of the crushing barrel 2 is connected with a rotating cylinder 31 through rotation, the left end of the rotating cylinder 31 is connected with a nozzle 32, and the lower part of the rotating cylinder 31 is connected with a water distribution pipe 34, which is a hose. One end of the shaft 12 penetrating through the right chamber wall of the processing machine 1 is fixedly connected with a crank 35, and the right end surface of the crank 35 is connected with a connecting rod 36 through a pin shaft, and the upper end of the connecting rod 36 is connected with a transmission rod 37 through a pin shaft, and the transmission rod 37 The upper end of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com