Shore hardness testing device and testing method

A Shore hardness and testing device technology, which is applied in the direction of measuring devices, testing material hardness, strength characteristics, etc., can solve the problems of test differences, reduce the authenticity of hardness tests, and low test efficiency

Active Publication Date: 2021-10-15

WUXI ENERGY NEW MATERIALS TECH CO LTD

View PDF18 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The test method is manually operated, and the test efficiency is low; and due to the different hand-held operations of the testers, there are large differences in the test, which reduces the authenticity of the hardness test

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

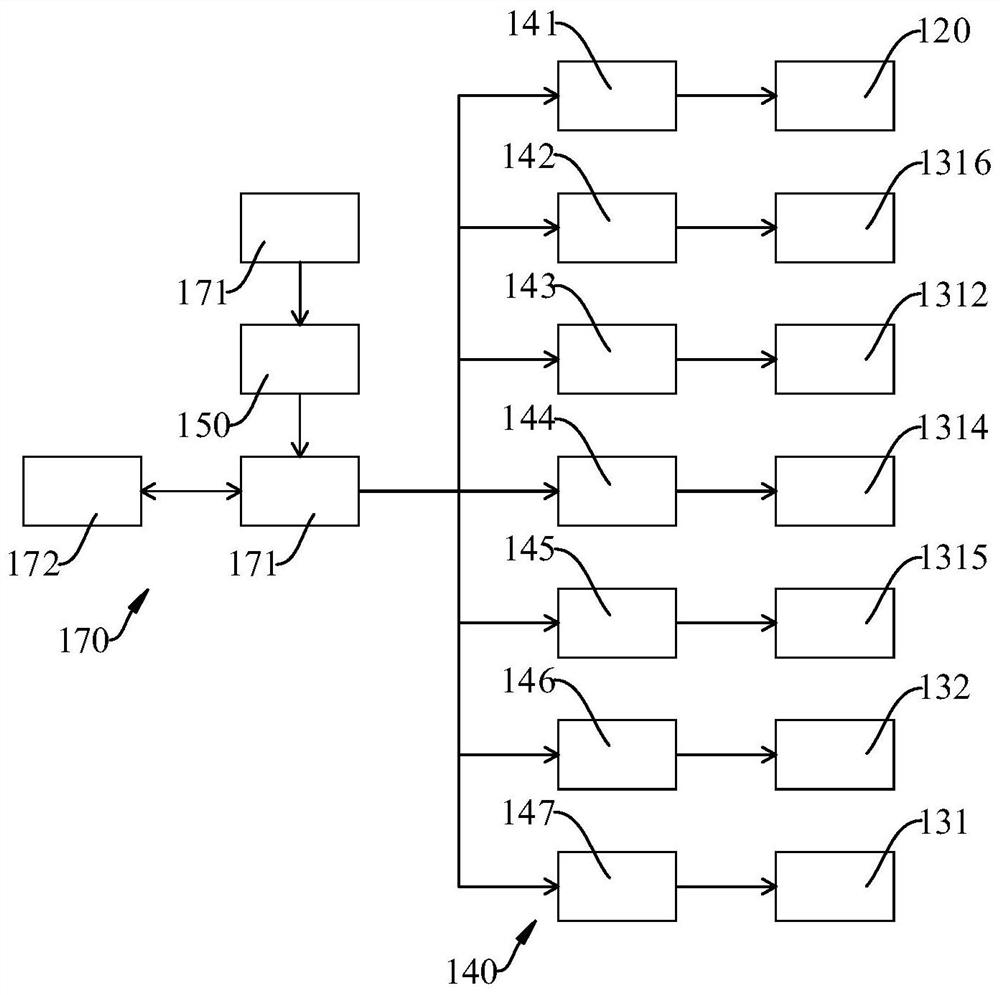

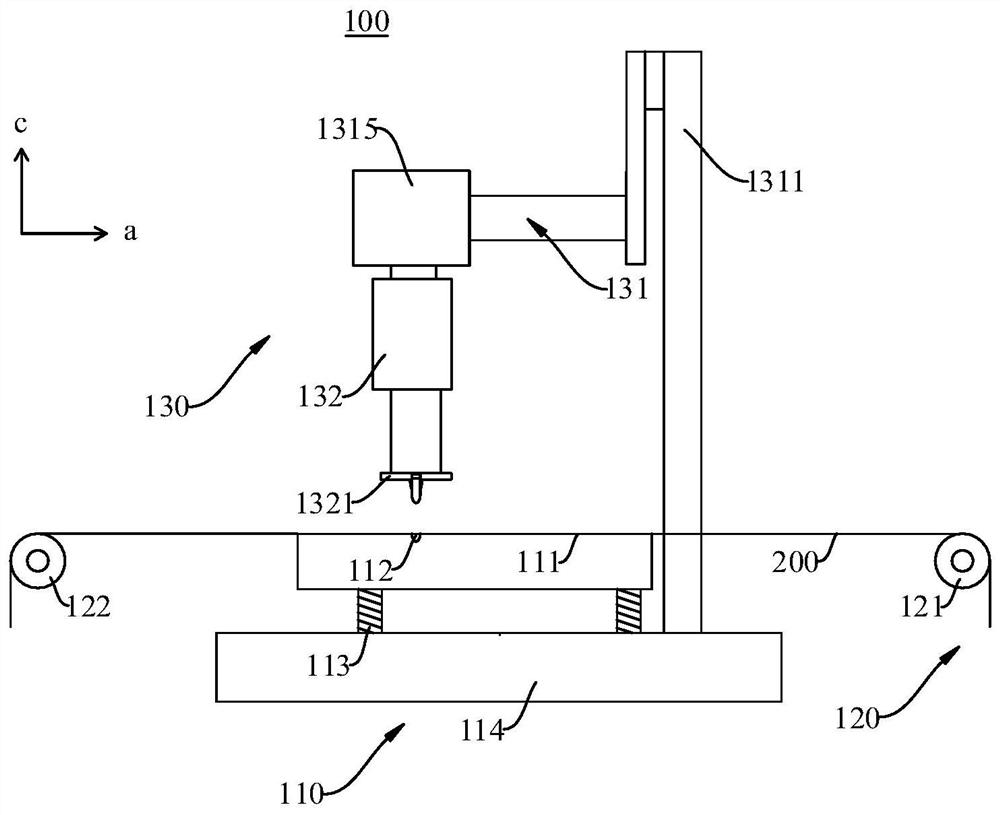

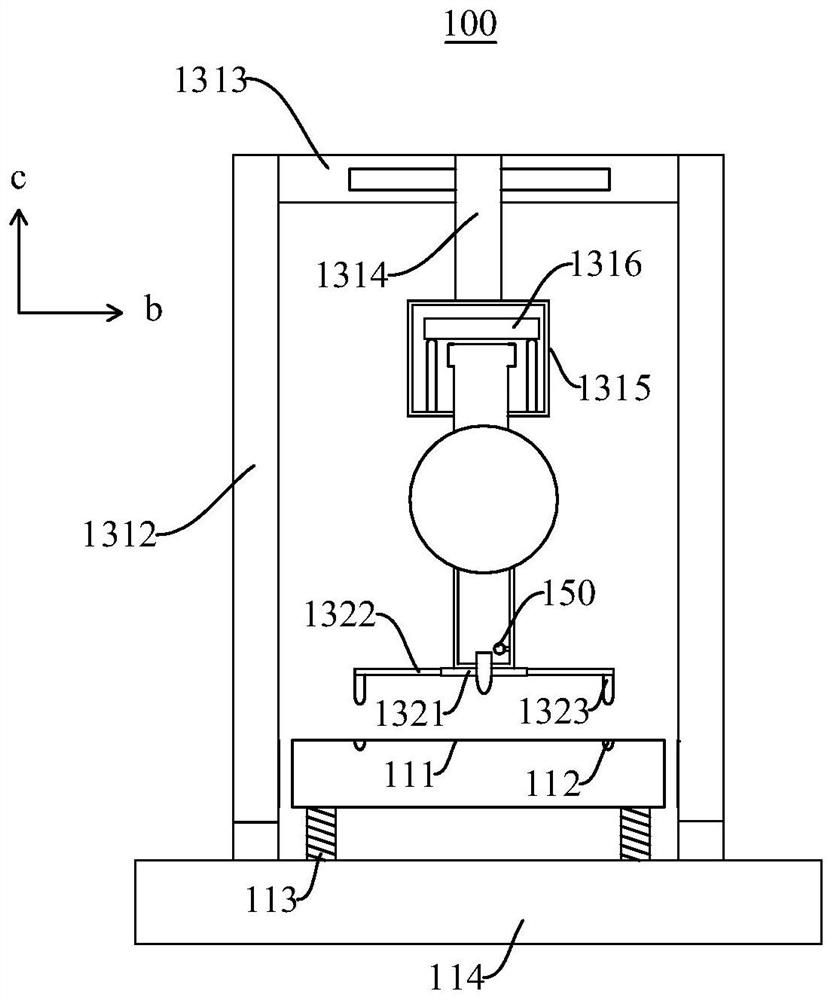

[0051] First, see Figure 1 ~ Figure 4 , the embodiment of the present application provides a Shore hardness testing device 100 , including: a testing platform 110 , a winding and unwinding unit 120 , a hardness testing unit 130 , a power unit 140 , a data acquisition unit 150 and a control unit 170 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a shore hardness testing device and a shore hardness testing method and belongs to the technical field of material performance testing. The device comprises a test platform, a winding and unwinding unit, a hardness testing unit, a power unit, a first driving structure control unit, a second driving structure, a data acquisition unit and a control unit, wherein the top of which is provided with a test tabletop; the winding and unwinding unit is provided with a winding assembly and an unwinding assembly which are located on two sides of the test table board in the first preset direction respectively; the hardness testing unit comprises a testing frame and a shore durometer; and the shore durometer is arranged corresponding to the test table board and is movably connected with the test frame along the direction vertical to the test table board; the power unit comprises a first driving structure and a second driving structure; the first driving structure is used for driving the winding and unwinding unit to perform winding and unwinding actions; the second driving structure is used for driving the shore durometer to be close to the test table board for testing; the data acquisition unit is used for collecting test data of the shore durometer; and the control unit is in communication connection with the power unit. The method is carried out by adopting the device, continuous and automatic testing can be realized, testing efficiency is relatively high, and testing accuracy is relatively high.

Description

technical field [0001] The present application relates to the technical field of material performance testing, in particular, to a Shore hardness testing device and testing method. Background technique [0002] Hardness is one of the most important quality characteristics of EVA foam cushioning materials, and it is an important indicator to characterize its cushioning performance. In the prior art, when testing the hardness of the EVA foam cushioning material, a manual hand-held Shore durometer is usually pressed on the surface of the EVA foam cushioning material, and the reading is recorded within 1 second to record the hardness value. The test method is manually operated, and the test efficiency is low; and due to the different hand-held operations of the testers, there are large differences in the test, which reduces the authenticity of the hardness test. Contents of the invention [0003] The purpose of this application is to provide a Shore hardness testing device an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/42G01N3/02

CPCG01N3/42G01N3/02G01N2203/0019G01N2203/0076G01N2203/0641

Inventor 邱长泉杨振誉刘德川于斌施蕾张大心蒋继芳茆中艳尹春梅刘海玲虞少波程跃

Owner WUXI ENERGY NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com